High-Rigidity SHF Shaft Holder

Essential components for linear motion systems, ensuring stable and reliable shaft fixation for precision equipment worldwide

Common Challenges with Standard Shaft Holders

Understanding the critical issues that affect your linear motion system performance and equipment reliability

Poor Coaxial Accuracy

Many market SHF holders suffer from coaxial deviation that causes shaft wobbling, reducing equipment stability and accelerating bearing wear in your precision systems.

Limited Compatibility

Incompatible dimensions force you to modify shafts or accept loose fits, leading to vibration issues and compromised motion accuracy in your automation equipment.

Wrong Material Selection

Aluminum holders that bend under load or steel holders that add excessive weight create performance problems, requiring costly equipment redesigns and replacements.

Insufficient Clamping Force

Weak mounting holes and thin clamping rings allow shaft slippage during operation, causing positioning errors and potential safety hazards in high-speed applications.

Unreliable Supply Chain

Unpredictable delivery times and inconsistent stock availability disrupt your production schedules, forcing expensive air freight or project delays that cost you customers.

Unclear Technical Specifications

Vague product descriptions and missing dimensional drawings lead to ordering mistakes and costly returns, wasting your engineering team's time on verification and troubleshooting.

Don't let poor quality shaft holders compromise your equipment performance

Get Expert ConsultationWhy YiCheng SHF Shaft Holders Stand Out

Engineered solutions that eliminate common problems and deliver superior performance for demanding industrial applications

±0.02mm Coaxial Precision

CNC-machined with strict tolerance control ensures perfect shaft alignment, eliminating wobble and extending bearing life by reducing uneven load distribution in your motion systems.

Premium Material Options

Choose between 6061/7075 aluminum for lightweight applications or S45C/alloy steel for heavy-duty loads, giving you the perfect balance of strength and weight for your specific requirements.

Universal Shaft Compatibility

Designed to fit both standard and non-standard shaft sizes from Ø8 to Ø60, with custom bore options available, ensuring seamless integration with your existing equipment without modifications.

Reinforced Clamping Design

Thickened clamping ring structure and precision-threaded mounting holes provide superior grip force, preventing shaft slippage even under high-speed operation and shock loads.

Factory-Direct Supply

Stable inventory management and established supply chain ensure consistent product availability with 7-14 day lead times, helping you maintain production schedules and avoid costly project delays.

Complete Technical Documentation

Receive detailed 3D models, 2D drawings with full dimensions, and material certifications for every order, enabling your engineers to design with confidence and avoid specification errors.

Experience the difference that precision engineering makes

Request Technical SpecificationsOur Most Popular SHF Models

Top-selling shaft holders trusted by automation engineers in USA, Europe, and Southeast Asia for reliable performance

SHF12

Enhanced clamping force with reinforced ring design delivers 30% stronger grip than standard models, perfect for high-speed CNC routers and laser cutting equipment that demand zero shaft movement.

Request Quote

SHF16

Superior coaxial accuracy within ±0.015mm ensures perfect alignment for precision automation systems, reducing bearing wear by up to 40% and extending equipment service life significantly.

Request Quote

SHF20

Premium alloy steel construction handles heavy loads and high-impact applications while maintaining lightweight efficiency for gantry systems and industrial robots operating in demanding environments.

Request Quote

SHF8

Lightweight aluminum design ideal for compact 3D printers and small-scale automation where space is limited but precision cannot be compromised, weighing only 18 grams without sacrificing stability.

Request Quote

SHF10

High stock availability with 3-day shipping ensures your production schedule stays on track, featuring versatile material options suitable for both lightweight plotters and medium-duty linear actuators.

Request Quote

SHF25

Industrial-grade performance with hardened steel construction and precision-ground surfaces delivers exceptional durability for heavy-duty CNC machines and hydraulic presses operating under continuous high stress.

Request QuoteReady to order your SHF shaft holders?

Get Bulk PricingTechnical Specifications

Detailed dimensional and performance parameters for precise system integration

| Model | shaft diameter | Size | Weight(g) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| W | L | T | F | G | B | S | |||

| SHF8 | Ф8 | 43 | 10 | 5 | 24 | 20 | 32 | 5.5 | 13 |

| SHF10 | Ф10 | 43 | 10 | 5 | 24 | 20 | 32 | 5.5 | 13 |

| SHF12 | Ф12 | 47 | 13 | 7 | 28 | 25 | 36 | 5.5 | 20 |

| SHF16 | Ф16 | 50 | 16 | 8 | 31 | 28 | 40 | 5.5 | 27 |

| SHF20 | Ф20 | 60 | 20 | 8 | 37 | 34 | 48 | 7 | 40 |

| SHF25 | Ф25 | 70 | 25 | 10 | 42 | 40 | 56 | 7 | 60 |

| SHF30 | Ф30 | 80 | 30 | 12 | 50 | 46 | 64 | 9 | 110 |

| SHF35 | Ф35 | 92 | 35 | 14 | 58 | 50 | 72 | 12 | 380 |

| SHF40 | Ф40 | 102 | 40 | 16 | 67 | 56 | 80 | 12 | 510 |

| SHF50 | Ф50 | 122 | 50 | 19 | 83 | 70 | 96 | 14 | 890 |

| SHF60 | Ф60 | 140 | 60 | 23 | 95 | 82 | 112 | 14 | 1500 |

How to Select the Right SHF Size

Follow our engineering-proven selection process to choose the perfect shaft holder that optimizes your linear motion system performance

Proper shaft holder selection directly impacts your equipment's precision, longevity, and maintenance costs. Our three-step process ensures you get the exact specifications your application demands.

Match Shaft Diameter

Select the SHF model that corresponds exactly to your linear shaft diameter. The bore size must match perfectly—even 0.1mm deviation can cause misalignment issues. Measure your shaft with calipers to ensure accuracy before ordering.

Choose Material by Load

Aluminum alloys (6061/7075) work perfectly for lightweight systems under 50kg load, offering excellent weight-to-strength ratio. For heavy-duty applications exceeding 100kg or high-impact environments, specify hardened steel or alloy steel construction to prevent deformation.

Verify Mounting Space

Check that your equipment has sufficient clearance for the holder's mounting hole pattern and overall dimensions. Pay special attention to hole spacing—standard patterns work for most applications, but custom configurations are available if your base plate has non-standard mounting.

📊 Quick Selection Reference Chart

| Application Type | Recommended SHF Model | Material Choice | Key Consideration |

|---|---|---|---|

| 3D Printers / DIY CNC | SHF8, SHF10 | Aluminum 6061 | Lightweight, sufficient rigidity |

| Laser Cutters / Plotters | SHF12, SHF16 | Aluminum 7075 | High precision, moderate speed |

| CNC Routers / Mills | SHF16, SHF20 | S45C Steel | Vibration resistance, durability |

| Industrial Robots | SHF20, SHF25 | Alloy Steel | Heavy loads, continuous operation |

| Gantry Systems | SHF25, SHF30 | Alloy Steel | Long span support, high load |

| Heavy Machinery | SHF35, SHF40, SHF50 | Hardened Steel | Extreme loads, shock absorption |

Not sure which model fits your specific application?

Get Free Selection ConsultationUnderstanding SHF Shaft Holders

Learn how SHF components work in linear motion systems and why they're essential for precision equipment reliability

SHF (Shaft Holder Fixed-end) components are precision-machined support units designed to secure linear shafts at fixed mounting points in motion control systems. Unlike bearing blocks that allow movement, SHF holders provide rigid shaft fixation to maintain alignment and prevent axial displacement during operation.

Fixed-End Support Function

SHF holders are installed at the stationary end of linear shaft systems to anchor the shaft securely. This fixed-point support prevents shaft rotation and axial movement while allowing smooth linear bearing travel along the shaft length.

Critical Role in Alignment

By maintaining precise coaxial alignment between parallel shafts, SHF holders ensure that linear bearings experience even load distribution, reducing friction, wear, and premature failure in your motion systems.

Difference from SK and SC Types

While SK holders use side-clamping for easy adjustment and SC types feature open structures for quick shaft installation, SHF holders provide superior clamping force through their closed-ring design, making them ideal for high-precision and high-load applications.

Why Linear Systems Need SHF

Without proper shaft fixation, linear motion systems suffer from shaft wandering, misalignment-induced binding, and accelerated bearing wear. SHF holders eliminate these issues by providing the rigid anchor point that precision equipment demands.

SHF Installation in Linear Motion Systems

Need help selecting the right shaft holder for your application?

Talk to Our EngineersWhy Leading Companies Choose YiCheng

Over a decade of manufacturing excellence delivering precision shaft holders to automation engineers worldwide

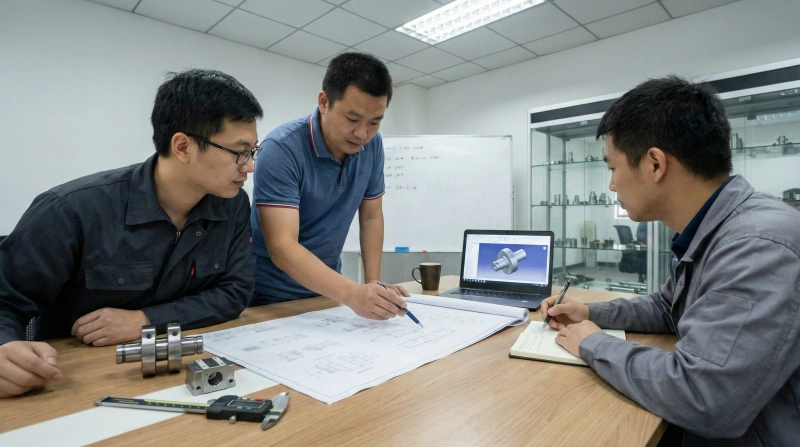

Expert Mechanical Engineering

Our in-house team of mechanical engineers understands the complexities of linear motion systems, providing expert guidance on component selection, system design, and troubleshooting to optimize your equipment performance.

Deep Equipment Knowledge

We don't just manufacture components—we understand how they integrate into complete automation systems. Our technical consultation helps you avoid costly mistakes and ensures compatibility with your existing equipment.

Custom Engineering Solutions

Need non-standard dimensions, special materials, or modified mounting configurations? Our engineering team designs and manufactures custom shaft holders tailored to your exact specifications without minimum order quantities.

Factory-Direct Reliability

As the manufacturer, we control every aspect of production—from raw material selection to final inspection—ensuring consistent quality and stable supply. Our established inventory management keeps your production schedules on track.

Complete Component Portfolio

Source all your linear motion components from one trusted supplier—linear shafts, guide rails, ball screws, linear bearings, and shaft holders. Streamline procurement, reduce lead times, and ensure perfect component compatibility.

Proven International Track Record

Ten years of successful exports to USA, UK, Germany, and Southeast Asian markets. Our components meet international quality standards and are trusted by automation engineers in the world's most demanding industrial environments.

Join hundreds of satisfied customers worldwide

Start Your PartnershipOEM/ODM Manufacturing Capabilities

From concept to production, we turn your custom shaft holder requirements into precision-engineered reality through our 6-step process.

Requirements Discussion

Share your specifications, application details, and performance needs with our engineering team to define the project scope.

Drawing & Sample Review

We provide detailed CAD technical drawings and 3D models for your verification and engineering approval.

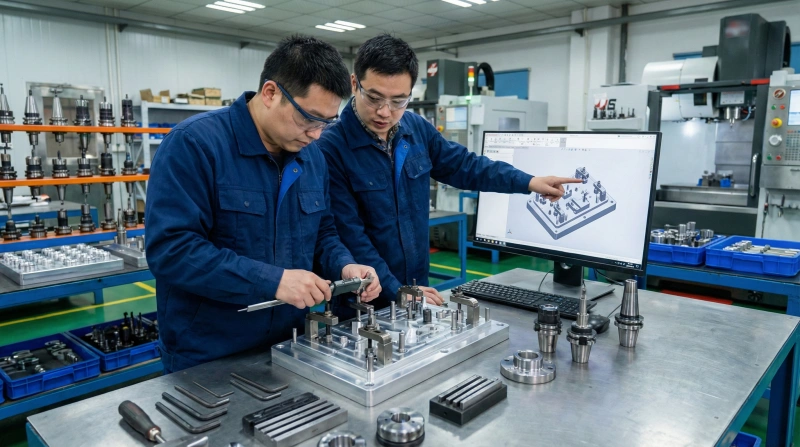

Tooling & Engineering

Custom mold design and fixture development specifically engineered for your non-standard component production.

Batch Production

High-precision 5-axis CNC machining delivers consistent quality across your entire production run with strict tolerances.

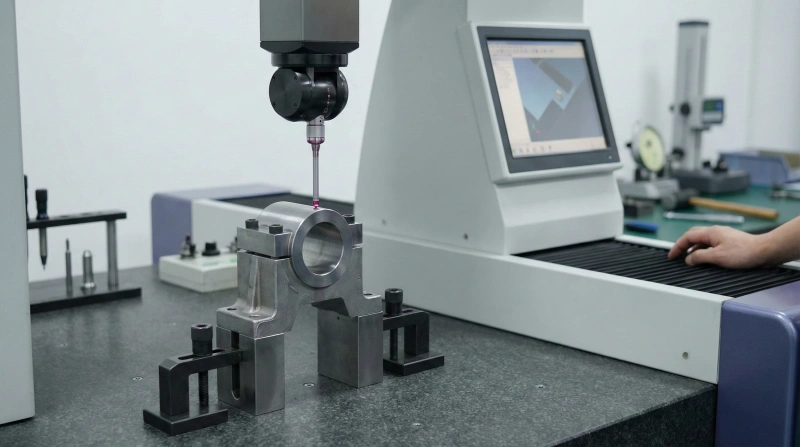

Quality Control

Rigorous multi-point inspection using CMM and gauges ensures every component meets your specifications exactly.

Secure Packaging

Professional custom packaging and global logistics ensuring your components arrive safely and on schedule.

Rigorous Quality Control Process

Six-stage inspection system ensures every SHF shaft holder meets international precision standards before shipment

Raw Material Inspection

Every batch of aluminum alloy and steel undergoes spectrometer testing to verify composition meets ASTM standards. Material certificates are maintained for full traceability.

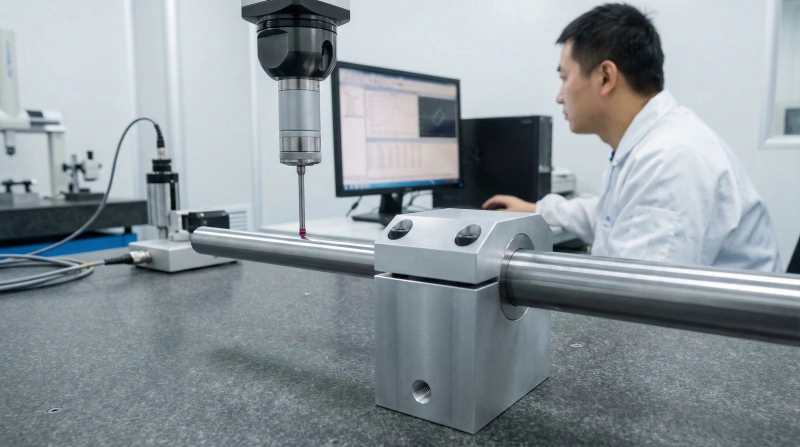

Precision Dimensional Check

CMM verification confirms bore diameter, mounting hole positions, and overall dimensions match specifications within ±0.01mm tolerance.

Coaxial Accuracy Testing

Precision runout gauges measure coaxial deviation to guarantee ±0.02mm alignment accuracy, preventing shaft wobble.

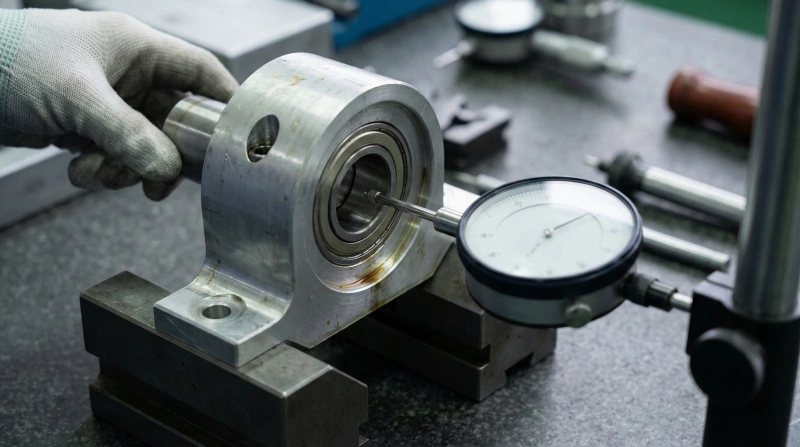

Thread Quality Verification

All mounting screw threads undergo go/no-go gauge testing to confirm proper thread depth, pitch, and tolerance.

Surface Treatment Inspection

Coating thickness gauges and adhesion tests verify anodizing, zinc plating, or black oxide finishes meet corrosion resistance requirements.

Functional Clamping Test

Sample units undergo practical installation and clamping force testing with actual linear shafts and torque verification.

🏆 Quality Certifications & Standards Compliance

- ISO 9001:2015 Quality Management

- ISO 14001:2015 Environmental

- RoHS Compliance Certified

- REACH Regulation Compliant

- CE Marking for EU Markets

- Material Test Certificates Available

Trusted Across Industries Worldwide

SHF shaft holders deliver precision performance in diverse automation equipment from manufacturing floors to research laboratories

Automated Transfer Equipment

Conveyor systems, pick-and-place robots, and material handling equipment rely on SHF holders to maintain precise shaft alignment during high-speed continuous operation, reducing downtime and maintenance costs significantly.

3D Printers & Additive Manufacturing

FDM printers and SLA machines demand ultra-precise linear motion for consistent layer quality. Our lightweight aluminum SHF holders provide rigid shaft support without adding unnecessary mass to moving gantries.

CNC Machining Centers

Multi-axis CNC mills and routers require unwavering shaft stability under cutting forces. Heavy-duty steel SHF holders absorb vibration and maintain positioning accuracy even when machining hard materials like steel and titanium.

Woodworking Machinery

Panel saws, edge banders, and CNC routers depend on reliable linear motion systems. SHF holders withstand dust, debris, and continuous operation while maintaining the precision needed for furniture-grade surface finishes.

Precision Inspection Equipment

Coordinate measuring machines and optical inspection systems require exceptional coaxial accuracy for repeatable measurements. Our ±0.02mm tolerance SHF holders ensure measurement integrity across thousands of inspection cycles.

Industrial Robot Systems

Collaborative robots and automated assembly lines need robust linear actuators that perform reliably in 24/7 production environments. Alloy steel SHF holders handle dynamic loads and provide the longevity these critical systems demand.

Curious how SHF holders can improve your specific equipment?

Discuss Your ApplicationProfessional Packaging Solutions

Multi-layer protection ensures your SHF shaft holders arrive in perfect condition, ready for immediate installation

Precision components deserve precision packaging. Our three-tier protection system prevents damage during international shipping while maintaining organized inventory management for your receiving team.

Individual Protective Sealing

Each SHF holder receives individual plastic bag sealing with foam inserts to prevent scratching and surface damage during handling.

- Anti-static PE bags protect surface finish

- Foam cushioning prevents impact damage

- Model labels for easy identification

- Moisture barrier for sea freight protection

Reinforced Carton Boxing

Individual units nest securely in compartmented cardboard boxes with corner reinforcement to withstand courier handling and stacking.

- Double-wall corrugated cartons

- Internal dividers prevent unit contact

- Specifications printed on exterior

- Stackable design saves warehouse space

Bulk Factory-Direct Packing

Large quantity orders ship in master cartons with pallet wrapping for optimal logistics efficiency without sacrificing product protection.

- Quantity verified before sealing

- Pallet strapping for freight stability

- Waterproof shrink wrap covering

- Customs documentation included

Special packaging requirements for your receiving process?

Request Custom PackagingGet Your Custom Quotation in 12 Hours

Tell us about your shaft holder requirements and our engineering team will respond with detailed specifications and competitive pricing