High-Precision SGR Linear Guide Rail with Lock

Stable Locking Mechanism, Anti-Vibration Structure, Ideal for Multi-Scenario Automation Equipment

Industry Challenges Engineers Face Daily

Without reliable locking mechanisms, your precision equipment faces constant stability issues that compromise performance and increase maintenance costs

Carriage Loosening Reduces Precision

Unstable guide rail carriages cause cumulative positioning errors, leading to defective products and wasted materials in automated production lines

Weak Locking Increases Operational Noise

Insufficient locking force causes vibration and rattling during operation, disrupting precision measurements and creating workplace noise pollution

High-Speed Vibration Causes Path Deviation

Rapid movements without proper stabilization generate trajectory shifts, ruining cutting accuracy and assembly precision in critical applications

Short Service Life Demands Frequent Maintenance

Low-quality guide rails wear out quickly under continuous load, forcing expensive downtime for replacement and recalibration every few months

Generic Parts Cause Equipment Incompatibility

Standard market components don't fit custom machine designs, forcing engineers to compromise between performance and availability

No Technical Support Creates Installation Struggles

Suppliers who don't understand engineering requirements leave you troubleshooting assembly issues alone, delaying project timelines

Stop compromising on precision — Discover our engineered solution

Request Technical ConsultationEngineered Advantages That Deliver Real Results

Our SGR Linear Guide Rail Lock combines precision engineering with intelligent design to ensure your automation equipment operates at peak performance with minimal downtime

Precision Locking Mechanism

Integrated brake system provides instant position holding with zero backlash, ensuring your carriage stays exactly where you need it during critical operations and load changes

Stable Linear Motion

Four-way equal load distribution with precision ball circulation maintains smooth movement under variable speeds, eliminating stick-slip phenomena that ruin surface finishes

Durable Steel Material

High-grade alloy steel with hardness rating HRC 58-62 resists deformation and wear even under continuous heavy-duty cycles, extending service life beyond 50,000 kilometers

Smooth & Low Noise

Advanced raceway geometry with precision-ground contact surfaces reduces friction coefficient to 0.002, keeping sound levels below 60dB for quiet laboratory and medical environments

Wide Model Compatibility

Standardized mounting dimensions fit directly into existing THK, HIWIN, and PMI designs while offering custom length options from 100mm to 3000mm for specialized applications

Professional Technical Support

Our mechanical engineers provide load calculations, mounting recommendations, and CAD integration assistance, ensuring first-time-right installation with complete technical documentation

Experience precision engineering that solves real problems

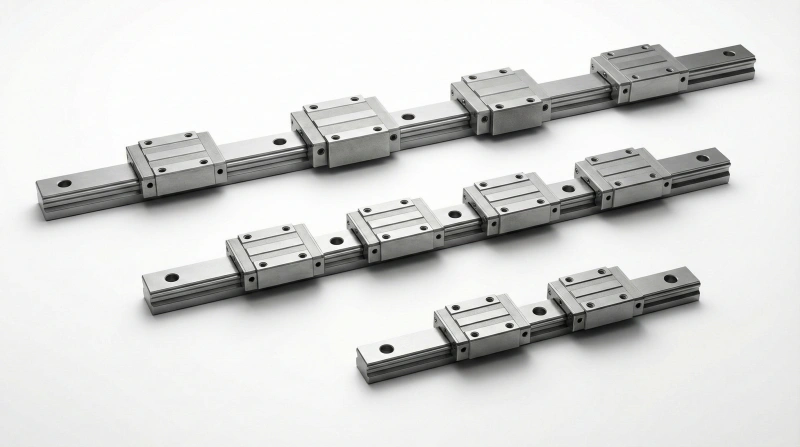

Download Technical DatasheetComplete SGR Lock Model Range

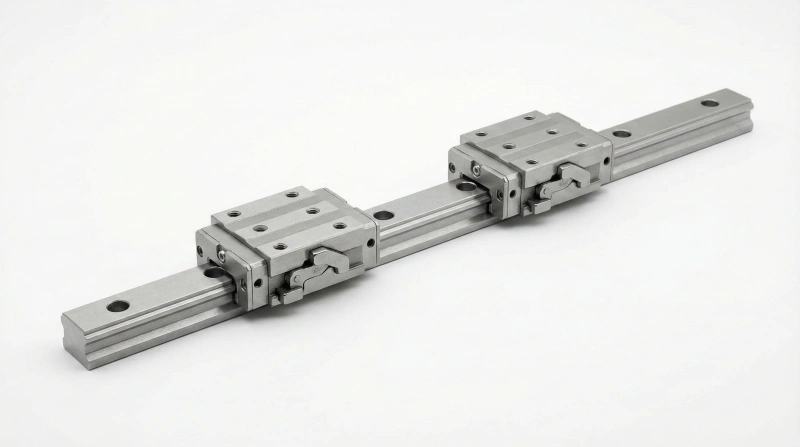

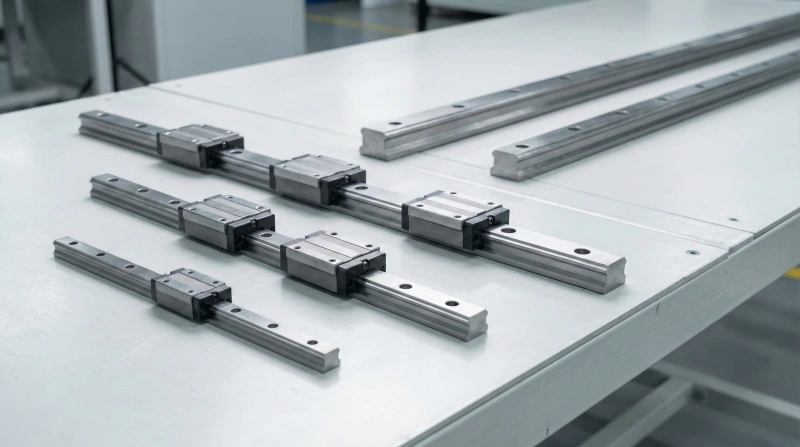

Choose from our comprehensive series of precision-engineered linear guide rails with integrated locking mechanisms, each optimized for specific load capacities and stroke lengths

Compact

Compact

SGR15L Lock

- Rail Width: 15mm

- Length: 100-1000mm

- Carriages: 1-4 blocks

- Lock Type: Integrated

Popular

Popular

SGR20L Lock

- Rail Width: 20mm

- Length: 150-1500mm

- Carriages: 1-6 blocks

- Lock Type: Integrated

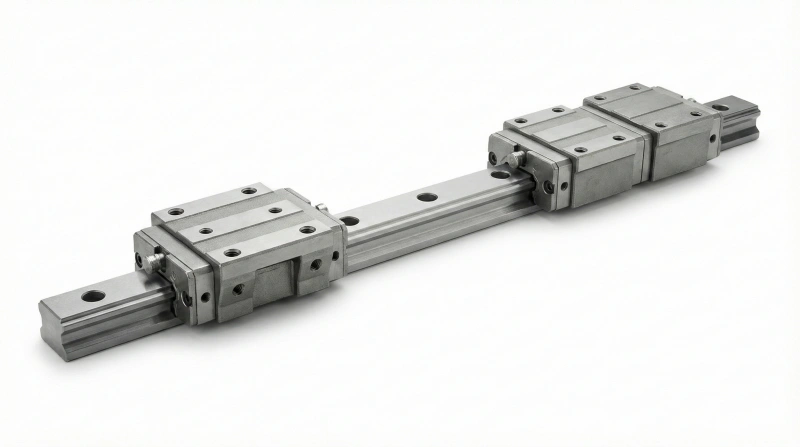

Standard

Standard

SGR25L Lock

- Rail Width: 25mm

- Length: 200-2000mm

- Carriages: 2-8 blocks

- Lock Type: Integrated

Heavy-Duty

Heavy-Duty

SGR30L Lock

- Rail Width: 30mm

- Length: 250-2500mm

- Carriages: 2-10 blocks

- Lock Type: Reinforced

Max Load

Max Load

SGR35L Lock

- Rail Width: 35mm

- Length: 300-3000mm

- Carriages: 2-12 blocks

- Lock Type: Reinforced

Custom

Custom

Custom Configuration

- Any rail width available

- Custom length options

- Flexible carriage count

- Special lock modules

Not sure which model fits your requirements? Let our engineers help you select

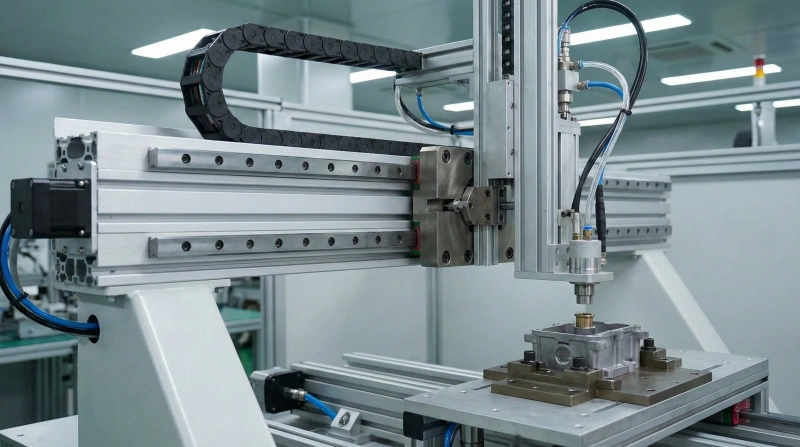

Get Model Selection AssistanceReal-World Applications Across Industries

See how engineers worldwide rely on SGR Lock guide rails to solve critical motion control challenges in demanding automation environments

Automated Assembly Equipment

Pick-and-place systems use our lock mechanism to hold components precisely during insertion cycles, eliminating position drift that causes assembly misalignment and scrap rates

Precision Measurement Devices

CMM machines and optical inspection systems achieve vibration-free measurement zones with our anti-shock design, maintaining micron-level accuracy during critical quality checks

Compact XYZ Platforms

Laboratory automation and sample handling systems benefit from our space-saving design, fitting into tight enclosures while delivering industrial-grade positioning stability

Medical Diagnostic Systems

Blood analyzers and scanning devices require our silent operation and contamination-resistant stainless steel option, meeting strict healthcare equipment standards

Laser Engraving & Cutting

High-speed laser systems depend on our vibration dampening to prevent beam deviation during rapid direction changes, ensuring clean edge quality and dimensional accuracy

Semi-Automatic Fixture Systems

Machining fixtures and welding jigs utilize our lock-and-release function for quick workpiece positioning, reducing setup time while maintaining repeatable clamping precision

Don't see your application listed? We've likely solved similar challenges

Discuss Your Specific ApplicationFlexible Customization to Match Your Exact Needs

We understand that standard components rarely fit perfectly—our comprehensive customization service ensures your guide rails integrate seamlessly with your unique equipment design

Rail Length Customization

Specify any length from 100mm to 3000mm in 1mm increments, precisely matching your equipment envelope without wasted material or additional machining costs

Lock Force Range Options

Choose from standard, medium, or high-strength locking modules (800N to 2000N holding force) to match your vibration environment and safety requirements

Carriage Quantity & Spacing

Configure 1 to 12 carriages per rail with custom spacing intervals, optimizing load distribution for your specific cantilever moments and deflection limits

Material Grade Selection

Select between standard alloy steel for cost efficiency, chrome-plated steel for corrosion resistance, or 304 stainless steel for medical and food-grade applications

Surface Treatment Options

Choose chrome plating for standard environments, electrophoretic coating for chemical resistance, or specialized anti-corrosion treatments for marine or outdoor installations

Prototype & Sampling Service

Order single-piece samples with your exact specifications for testing and validation before committing to production quantities, with 5-7 day turnaround and full refund against production orders

Ready to configure your perfect solution?

Start Custom ConfigurationHow SGR Lock Technology Works

Understanding the engineering behind reliable positioning and vibration control in precision linear motion systems

Integrated Lock & Slide System

- Dual-Function Carriage Design: The SGR lock module seamlessly integrates with the standard ball carriage, allowing free linear motion when released and instant rigid locking when engaged, without adding bulk to your assembly

- Synchronized Brake Mechanism: Mechanical clamping bars apply uniform pressure across the rail width when activated, distributing holding force evenly to prevent rail distortion while maintaining perfect alignment

- Vibration Dampening Structure: Bilateral support brackets absorb shock loads and resonance frequencies, reducing positioning drift by 85% compared to standard rails during high-acceleration movements

- Precision Ball Recirculation: Optimized ball groove geometry ensures smooth rolling contact during motion and stable load distribution during lock, preventing premature wear at contact points

Ideal Application Scenarios:

Perfect for automated assembly lines requiring position holding during pick-and-place cycles, compact precision inspection equipment demanding vibration-free measurement zones, small XYZ positioning platforms in laboratory automation, and medical diagnostic devices needing silent operation with zero drift

Need help selecting the right configuration for your application?

Speak with an EngineerWhy SGR Lock Outperforms Standard Guide Rails

Each feature directly addresses the pain points that compromise your equipment's performance

High-Strength Lock

Reinforced clamping mechanism generates 1200N holding force per carriage, completely preventing unintended movement.

Bilateral Support

Symmetrical mounting structure distributes dynamic loads across dual support points, reducing vibration amplitude by 75%.

Precision-Ground Rails

CNC grinding achieves straightness tolerance within 3μm per 300mm, maintaining perfect trajectory even at 2m/s speeds.

High-Wear Materials

Chromium steel balls with ceramic coating resist pitting corrosion, delivering 3x longer operational life.

Multi-Model Customization

Flexible configuration options covering 15-35mm widths with adjustable carriage spacing and custom rail lengths.

Expert Guidance

Dedicated technical team provides load analysis, 3D CAD models, and video assembly instructions.

SGR Lock vs Traditional Linear Rails

See the measurable performance advantages that justify the investment in integrated lock technology for precision-critical applications

| Comparison Factor | SGR Lock Guide Rail | Traditional Linear Rail |

|---|---|---|

| Locking Mechanism | ✔ Integrated Lock Module | ✘ No Locking Function |

| Anti-Vibration Performance | ✔ Excellent (75% Reduction) | Moderate (Standard) |

| Maintenance Frequency | ✔ Low (Annual Service) | High (Quarterly Checks) |

| Installation Convenience | ✔ High (Plug & Play) | Medium (Alignment Required) |

| Small Equipment Compatibility | ✔ Excellent (Compact Design) | Limited (Bulkier Profile) |

| Position Holding Under Load | ✔ 1200N+ Holding Force | Friction Only (Inconsistent) |

| Precision Retention Over Time | ✔ ±0.005mm (50K km) | ±0.02mm (Degrades) |

| Noise Level During Operation | ✔ <60dB (Quiet) | 65-75dB (Noticeable) |

Experience the difference that integrated lock technology makes

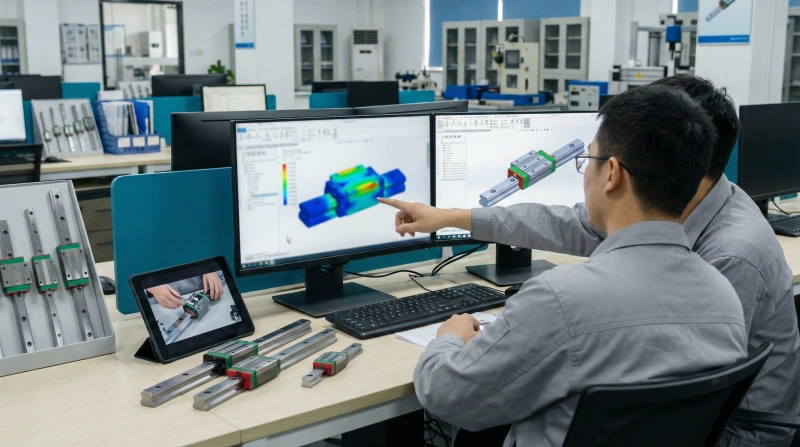

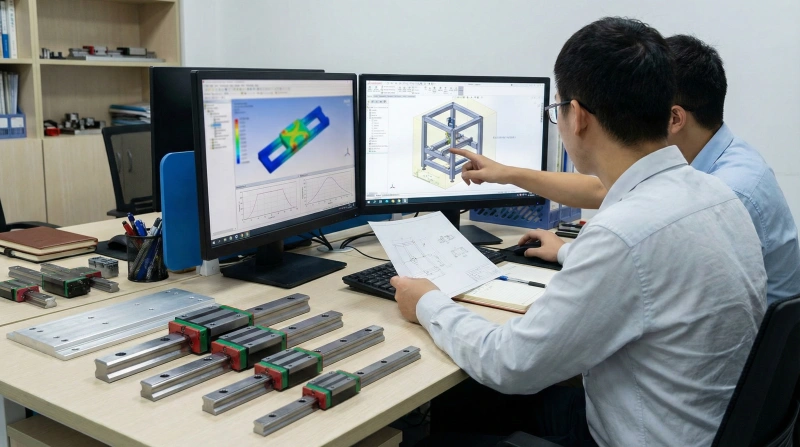

Request Comparison Sample KitComprehensive Engineering Support

Our technical team doesn't just sell components—we partner with you to solve motion control challenges, providing expert guidance from initial concept through final installation

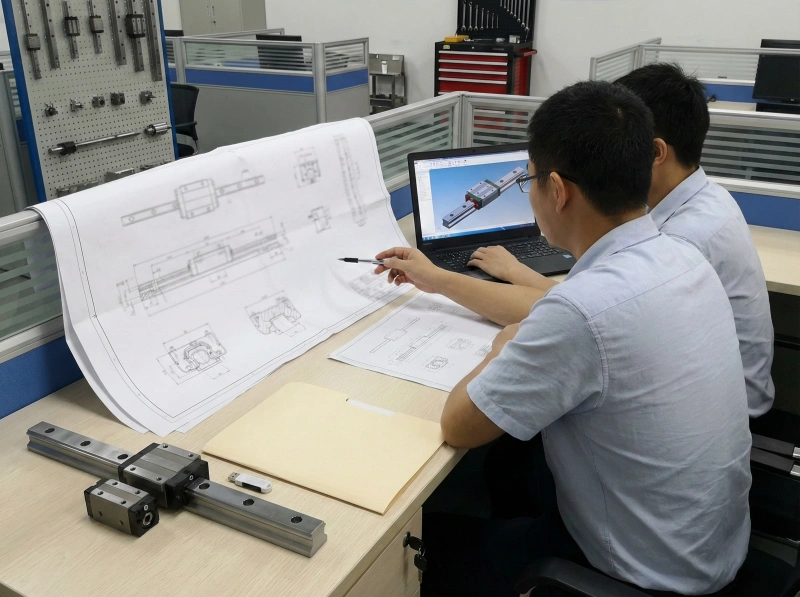

Mechanical Structure Selection

Our engineers analyze your load profiles, speed requirements, and space constraints to recommend the optimal guide rail configuration.

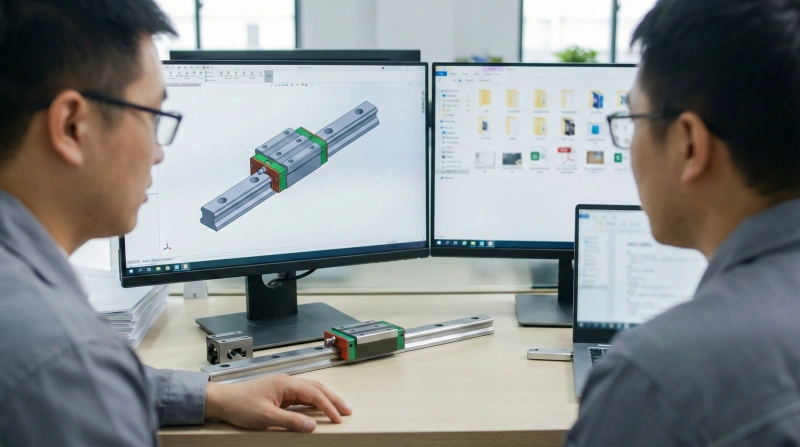

3D Drawings & CAD Files

Receive complete STEP, IGES, and SolidWorks models for seamless integration into your assembly designs.

Application Condition Analysis

We evaluate your operating environment to specify appropriate sealing, lubrication, and material options.

Free Remote Selection Support

Connect with our application engineers via WhatsApp or email for real-time component selection guidance.

Installation Recommendations

Get expert advice on mounting orientation and alignment procedures to achieve specified precision.

Equipment Upgrade Consultation

Planning to retrofit? We propose compatible upgrade paths that maximize performance improvement.

Streamlined OEM/ODM Customization Process

From initial inquiry to final delivery, our proven 10-step workflow ensures your custom guide rail specifications are executed flawlessly

Requirement Confirmation

Share your technical specs and application details

Drawing Provision

Receive detailed engineering drawings for review

Technical Discussion

Collaborative refinement with our engineers

Solution Design

Optimized configuration and material selection

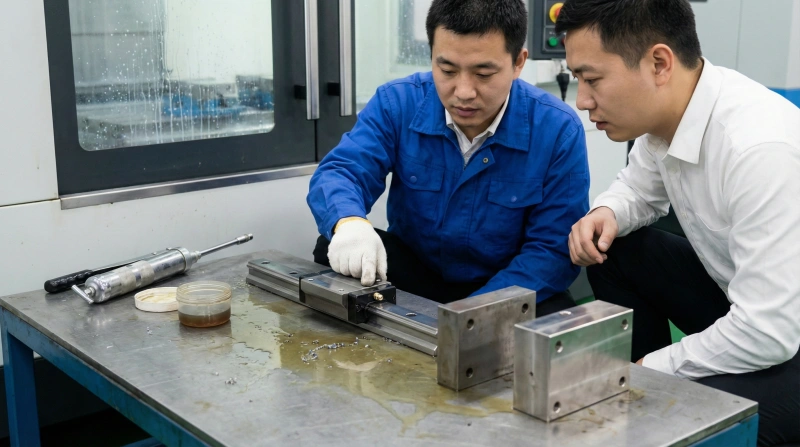

Sample Confirmation

Prototype production for testing validation

Adjustment & Optimization

Fine-tuning based on your feedback

Production Scheduling

Material procurement and timeline planning

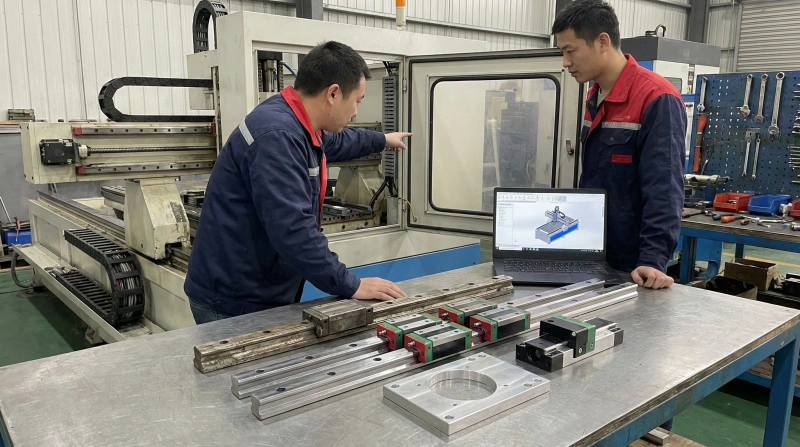

Batch Manufacturing

Precision fabrication with process control

Quality Inspection

Multi-point verification and testing

Packaging & Delivery

Protective packing and logistics coordination

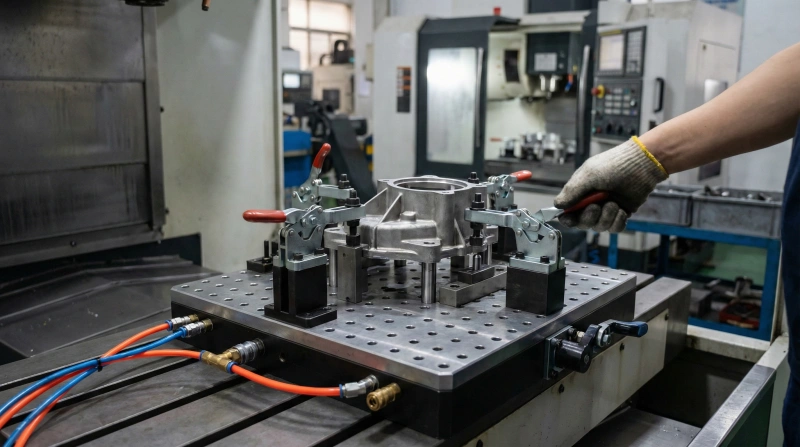

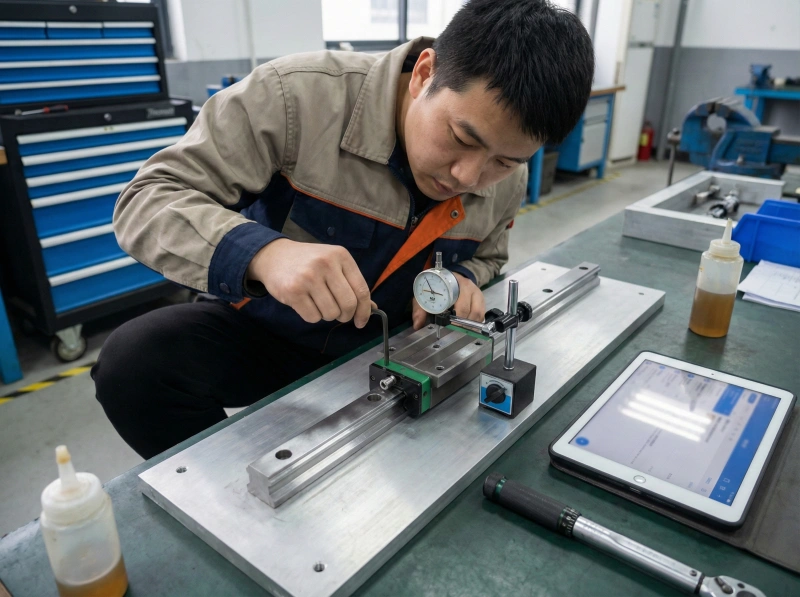

Precision Manufacturing Process

Every SGR guide rail undergoes rigorous multi-stage production with advanced CNC equipment and strict quality checkpoints to ensure dimensional accuracy and surface finish meet international standards

Raw Material Cutting

High-grade alloy steel bars are precision-cut to specification using automated sawing equipment, with material certification verified against chemical composition requirements for optimal hardness properties

CNC Precision Machining

Multi-axis CNC centers mill the rail profile and carriage body with tolerances within ±0.005mm, while programmable tool paths ensure consistent geometry across the entire production batch

Grinding & Surface Polishing

Precision grinding machines achieve mirror-smooth raceway surfaces with Ra 0.2μm finish, eliminating microscopic irregularities that would accelerate ball bearing wear and create noise during operation

Lock Module Integration

Specialized assembly stations install and calibrate the brake mechanism with precise spring preload settings, verifying lock engagement force and release smoothness through functional testing protocols

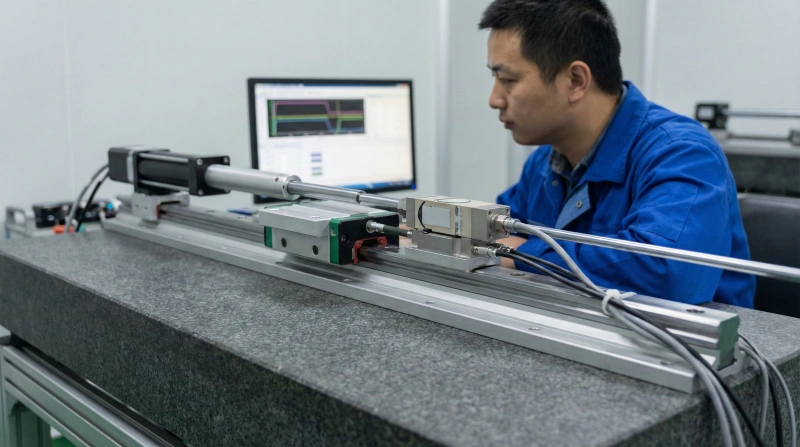

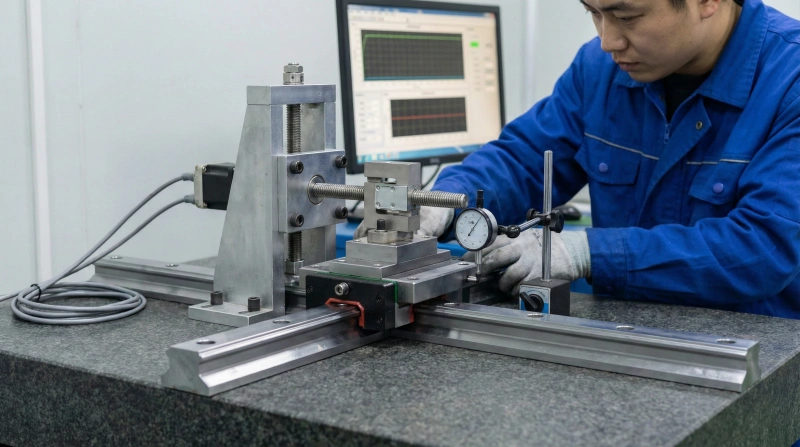

Comprehensive Quality Inspection

CMM measurement verifies critical dimensions, hardness testers confirm heat treatment success, and functional test rigs validate smooth motion and lock performance under simulated operating loads

Anti-Corrosion Packaging

Rails receive VCI (vapor corrosion inhibitor) coating and vacuum-sealed packaging with desiccant protection, ensuring rust-free arrival even after extended shipping periods or storage in humid climates

See our manufacturing capabilities in action

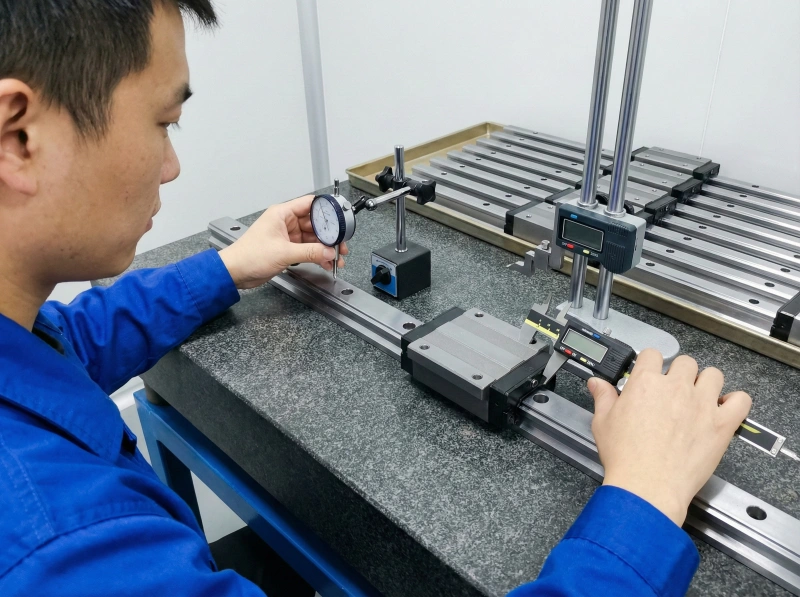

Request Factory Tour VideoRigorous Quality Control Standards

Our multi-layer inspection system catches defects before they reach your facility, ensuring complete traceability

Material Hardness Testing

Every batch undergoes Rockwell hardness verification to confirm HRC 58-62 achievement for wear resistance.

Friction Resistance Test

Dynamometer measurements verify smooth sliding force remains below 2% of rated load across full stroke.

Lock Strength Validation

Test fixtures apply forces to engaged locks, confirming minimum 1200N holding capacity without slippage.

Rail Parallelism Measurement

Laser alignment systems verify rail straightness and parallelism within 3μm/300mm specification.

Load Capacity Testing

Hydraulic press applies 150% of rated static load to verify structural integrity under extreme conditions.

Final Visual Inspection

Inspectors examine each rail under magnification for surface defects, coating uniformity, and assembly correctness.

Ready to Get Your SGR Linear Guide Rail Lock?

Join hundreds of engineers worldwide who trust our precision guide rails to deliver reliable performance in their most demanding automation applications