Common Challenges Equipment Manufacturers Face

We understand the critical issues that disrupt your production schedules and compromise machine performance. Here are the most frequent problems our clients encounter before partnering with us.

Unstable Lead Times

Unpredictable delivery schedules delay project timelines and frustrate customers waiting for equipment installations and upgrades.

Accuracy Deviations

Inconsistent precision levels cause positioning errors that affect final product quality and increase rejection rates in manufacturing processes.

Poor Compatibility

Guides that don't integrate seamlessly with existing systems require costly redesigns and extended installation timeframes.

Weak Mounting Systems

Inadequate fixing methods lead to vibration issues and reduced stability during high-speed operations and heavy load applications.

Noise & Rough Movement

Excessive noise and jerky motion compromise equipment performance and create uncomfortable working environments for operators.

Limited Technical Support

Suppliers who lack engineering expertise can't provide proper guidance on selection, installation, and troubleshooting critical application issues.

Ready to solve these challenges with precision-engineered solutions?

Discuss Your RequirementsSuperior Performance Features That Drive Results

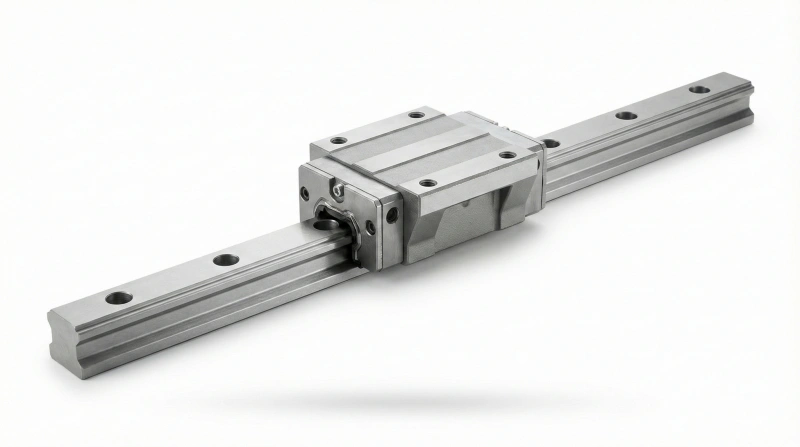

Our SGR Linear Guides deliver measurable advantages that translate directly into improved machine performance, reduced maintenance costs, and enhanced production efficiency for your business.

High Precision Guarantee

Achieve positioning accuracy within ±0.01mm through precision-ground rail surfaces and matched tolerances that ensure consistent performance across thousands of cycles.

Heavy Duty Options

Support loads exceeding 3000N with reinforced block structures and wider rail profiles designed specifically for demanding industrial applications and continuous operation.

Low Noise Operation

Experience whisper-quiet motion below 60dB through optimized ball circulation paths and advanced lubrication systems that minimize friction and vibration.

Custom Travel Lengths

Match your exact specifications with rail lengths from 100mm to 6000mm without compromise, eliminating the need for workarounds or modified designs.

Superior Wear Resistance

Extend service life beyond 50km of travel distance using hardened steel construction and protective coatings that resist corrosion and abrasive contamination.

High Repeatability

Maintain positioning consistency within ±0.005mm over extended production runs through precise preload control and optimized ball-to-raceway contact geometry.

Why Equipment Manufacturers Choose Us

We deliver more than components – we provide complete solutions backed by engineering expertise, quality assurance, and reliable partnership that your production schedule depends on.

Reliable Delivery System

Never miss a deadline with our streamlined production scheduling that guarantees standard items ship within 7-10 business days and custom configurations within 15 working days.

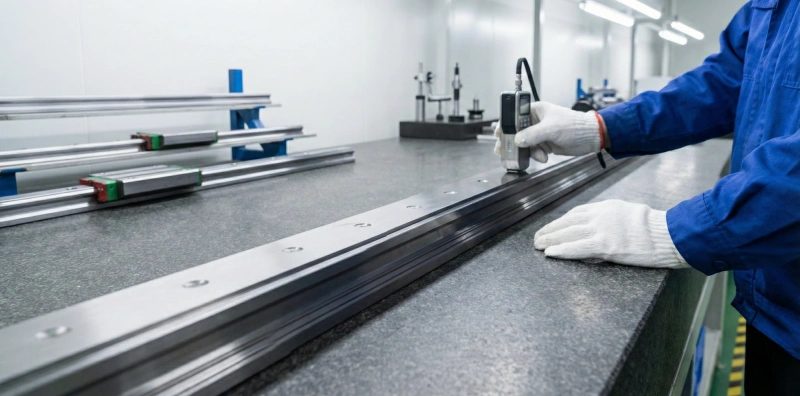

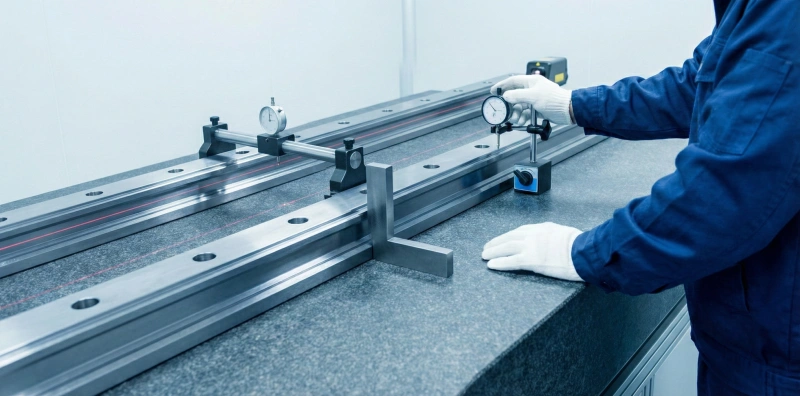

100% Full Inspection

Every guide undergoes complete dimensional verification, straightness measurement, and motion smoothness testing before packaging to ensure zero defects reach your facility.

One-on-One Engineering Support

Communicate directly with experienced mechanical engineers who understand load calculations, mounting configurations, and application-specific requirements for optimal selection.

Universal Compatibility Design

Integrate seamlessly with major industry standards including ISO 9001 dimensions and mounting hole patterns that match leading brands for easy retrofitting.

Factory Direct Pricing

Reduce component costs by 20-35% compared to distributor pricing while maintaining premium quality through efficient manufacturing and direct-to-customer logistics.

Global Client Portfolio

Join manufacturers across North America, Europe, and Asia who trust our guides in CNC machines, automation equipment, and precision instruments operating in their facilities today.

Partner with a supplier who understands your technical challenges.

Request Technical ConsultationHot Products - Featured SGR Linear Models

Industry-proven configurations engineered for reliable performance across diverse automation applications. Each model offers customizable travel lengths to match your specific machine design requirements.

Can't find your required size? We manufacture custom configurations to exact specifications.

Request Custom ConfigurationTechnical Specifications

Detailed dimensional and performance parameters for precise system integration

| Model of guide | Assembly Height & Width | Guide Rail SGR | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H | W | W1 | H2 | DP | P | shaft diameter | weight/meter | T | m1 | m | |

| SGR10 | 23 | 28 | 28 | 17 | 6 | 60 | 6 | 1.2 | 8 | 8 | 4.5 |

| SGR15N | 32 | 38 | 38 | 18.5 | 6 | 120 | 6 | 1.3 | 8 | 8 | 4.5 |

| SGR15 | 32 | 46 | 46 | 18.5 | 6 | 120 | 6 | 2.1 | 8 | 8 | 4.5 |

| SGR20N | 36 | 47 | 47 | 22.5 | 6 | 120 | 8 | 2.5 | 9 | 9.5 | 5.5 |

| SGR20 | 36 | 60 | 60 | 22.5 | 6 | 120 | 8 | 3.5 | 9 | 9.5 | 5.5 |

| SGR25 | 44 | 69 | 69 | 26 | 7 | 120 | 10 | 4.5 | 10 | 11 | 6.5 |

| SGR35 | 55 | 100 | 90 | 35 | 8.5 | 160 | 12 | 7 | 12 | 14 | 8.5 |

| Model of slider | Slider Block SGB | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| H1 | L | B | L1 | S | No.of wheel | safe loading(N) | weight(KG/pc) | ||

| SGB10 | -3UU | 11 | 47 | 18.16 | 18 | M4 | 3 | 320 | 0.12 |

| SGB15N | -3UU | 12 | 60 | 26 | 26 | M5 | 3 | 490 | 0.12 |

| -4UU | 80 | 4 | 700 | 0.15 | |||||

| -5UU | 100 | 5 | 980 | 0.19 | |||||

| SGB15 | -3UU | 12 | 60 | 32 | 36 | M5 | 3 | 490 | 0.15 |

| -4UU | 80 | 4 | 700 | 0.15 | |||||

| -5UU | 100 | 5 | 980 | 0.18 | |||||

| SGB20N | -3UU | 12 | 81 | 38 | 30 | M6 | 3 | 700 | 0.2 |

| -4UU | 108 | 4 | 1000 | 0.3 | |||||

| -5UU | 135 | 5 | 1400 | 0.4 | |||||

| SGB20 | -3UU | 12 | 81 | 50 | 40 | M6 | 3 | 700 | 0.2 |

| -4UU | 108 | 4 | 1000 | 0.3 | |||||

| -5UU | 135 | 5 | 1400 | 0.4 | |||||

| SGB25 | -3UU | 16.5 | 100 | 57 | 45 | M8 | 3 | 1260 | 0.5 |

| -4UU | 133 | 4 | 1800 | 0.7 | |||||

| -5UU | 166 | 5 | 2600 | 0.8 | |||||

| SGB35 | -3UU | 18 | 140 | 82 | 62 | M10 | 3 | 2800 | 1.2 |

| -4UU | 185 | 4 | 4000 | 1.5 | |||||

| -5UU | 230 | 5 | 5500 | 1.9 | |||||

Proven Performance Across Industries

Our SGR Linear Guides deliver reliable motion control in demanding production environments worldwide. From precision manufacturing to automated assembly, equipment manufacturers trust our guides for critical positioning applications.

How to Select the Right SGR Model

Making informed selection decisions ensures optimal performance and longevity. Consider these four critical factors to match guide specifications with your application requirements and operating environment.

Speed Requirements

Operating velocity directly impacts guide selection and preload configuration. Higher speeds demand lighter preload to reduce friction heat generation while maintaining smooth motion quality.

- Low Speed (<0.5m/s): Medium or heavy preload for maximum rigidity

- Medium Speed (0.5-2m/s): Light to medium preload balances stiffness and smoothness

- High Speed (>2m/s): Light preload minimizes friction and heat generation

- Consider lubrication system for continuous high-speed operation

Load Capacity Analysis

Accurate load calculation prevents premature failure and ensures rated service life. Account for static weight, dynamic acceleration forces, and moment loads in all directions.

- Light Load (<30% capacity): Standard blocks provide adequate safety margin

- Medium Load (30-60% capacity): Consider dual blocks for improved stability

- Heavy Load (>60% capacity): Select larger rail size or wide-body blocks

- Apply 2-3x safety factor for shock loads and irregular duty cycles

Installation Space

Available mounting space constrains guide and block dimensions. Measure clearances carefully to ensure proper installation and maintenance access without machine redesign.

- Compact Space: Low-profile blocks reduce overall height requirements

- Standard Space: Flange blocks offer balanced dimensions and load capacity

- Unrestricted Space: Wide-body blocks maximize load and moment resistance

- Verify mounting hole patterns match existing machine structure

Operating Environment

Environmental conditions significantly affect guide performance and service life. Select appropriate sealing, materials, and protective features to match exposure conditions.

- Dusty Conditions: Enhanced seals and dust covers protect internal components

- High Temperature (>80°C): Special lubricants and material treatments required

- Corrosive Environment: Stainless steel construction and protective coatings

- Cleanroom Applications: Low-particle-emission designs with compatible lubricants

Still unsure which configuration best suits your application requirements?

Get Expert Selection AdviceSGR Linear vs. Traditional Linear Guide

Understanding key differences helps you make informed decisions about guide technology selection. This comparison highlights performance characteristics, cost factors, and application suitability for different linear motion requirements.

| Comparison Factor | SGR Linear Guide | Traditional Slide Guide |

|---|---|---|

| Positioning Accuracy | ±0.003-0.005mm Consistent over time |

±0.02-0.05mm Degrades with wear |

| Initial Cost | Higher upfront investment 20-40% more expensive |

Lower initial purchase Budget-friendly option |

| Installation Complexity | Straightforward mounting Standard hole patterns |

Complex alignment Requires skilled labor |

| Maintenance Requirements | Low maintenance Lubrication every 500-1000km |

Frequent adjustment Regular cleaning and lubrication |

| Application Range | Universal compatibility All automation types |

Limited to simple motion Low-speed applications |

| Service Life | 50,000+ km travel 5-10 years typical |

10,000-20,000 km 2-4 years typical |

| Total Cost of Ownership | Lower long-term cost Reduced downtime |

Higher lifetime cost Frequent replacement |

Key Advantage Summary

SGR Linear Guides deliver superior precision, longer service life, and lower total ownership costs despite higher initial investment. The self-lubricating design and maintenance-free operation significantly reduce labor costs and production downtime. For applications requiring consistent accuracy over extended periods, the performance advantages justify the price premium through improved product quality and reduced replacement frequency.

Flexible Customization Capabilities

Our manufacturing flexibility ensures perfect integration with your equipment design. Specify exact dimensions, materials, and features to eliminate costly modifications and accelerate your time-to-market.

Travel Length Customization

Specify any rail length from 100mm to 6000mm in 1mm increments, matching your exact stroke requirements without compromise or workarounds that complicate machine design.

Rail Width Options

Choose from standard sizes or specify custom widths to optimize load capacity and footprint for your application, ensuring proper safety factors and mechanical performance.

Mounting Hole Pattern

Modify block mounting holes to match existing machine structures, eliminating adapter plates and reducing assembly complexity while maintaining structural integrity.

Material Selection

Select from carbon steel, stainless steel 304/316, or specialized alloys based on environmental conditions including corrosion resistance and temperature requirements.

Heavy-Duty Reinforcement

Upgrade to reinforced block structures with additional ball rows and thicker walls for extreme load applications exceeding standard capacity ratings by up to 50%.

Environmental Protection

Add dust covers, enhanced seals, corrosion-resistant coatings, or high-temperature lubricants to protect guides in challenging industrial environments and extend service life.

Every customization is engineered to enhance performance and simplify integration.

Submit Custom RequirementsTransparent OEM / ODM Workflow

Our systematic 10-step process ensures accurate specifications, rigorous quality verification, and on-time delivery for every custom order. Clear communication at each stage eliminates surprises and delays.

Requirements Consultation

Share your specifications, application details, and technical requirements through our contact form.

Drawing Confirmation

Receive detailed technical drawings showing all dimensions, tolerances, and specifications for approval.

Quotation Delivery

Get comprehensive pricing including unit costs, tooling fees, and estimated delivery timeline.

Sample Production

Receive physical prototypes manufactured to exact specifications for validation of design.

Client Approval

Review samples, test reports, and dimensional inspection data. Approve for mass production.

Batch Manufacturing

Full-scale production begins using approved specifications and validated process parameters.

Precision Testing

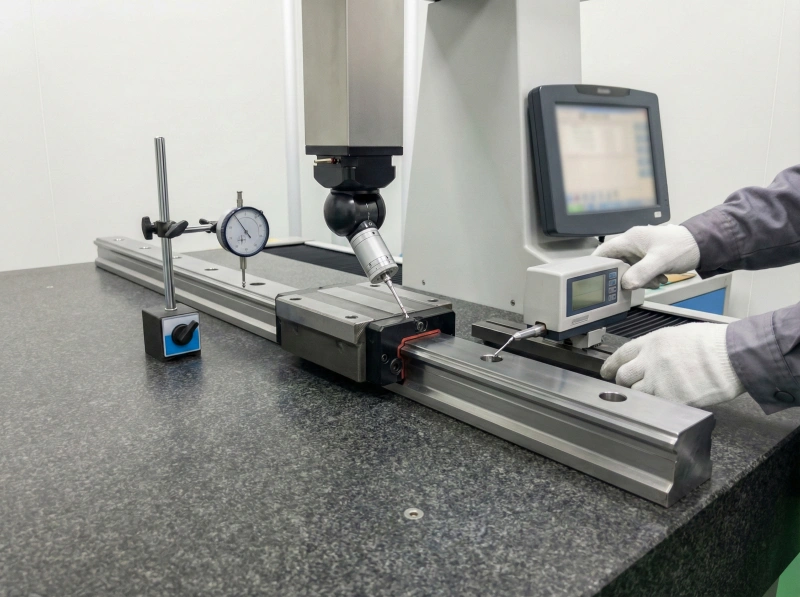

CMM inspection verifies dimensional accuracy, straightness, and surface finish.

Quality Verification

100% inspection of critical dimensions plus statistical sampling ensures consistent quality.

Professional Packaging

Individual protection with rust-prevention oil and export-grade wooden crates.

Logistics & Support

Shipment via express or freight with full tracking and technical after-sales support.

Every step minimizes risk and maximizes first-time-right production success.

Initiate Custom ProjectPrecision Manufacturing Process

Advanced CNC machining and rigorous quality control at every production stage ensure dimensional accuracy, surface quality, and performance consistency that meet international standards.

Material Cutting

High-carbon chromium bearing steel bars cut to precise lengths with automated saws, ensuring minimal material waste and consistent starting dimensions for subsequent machining operations.

CNC Precision Machining

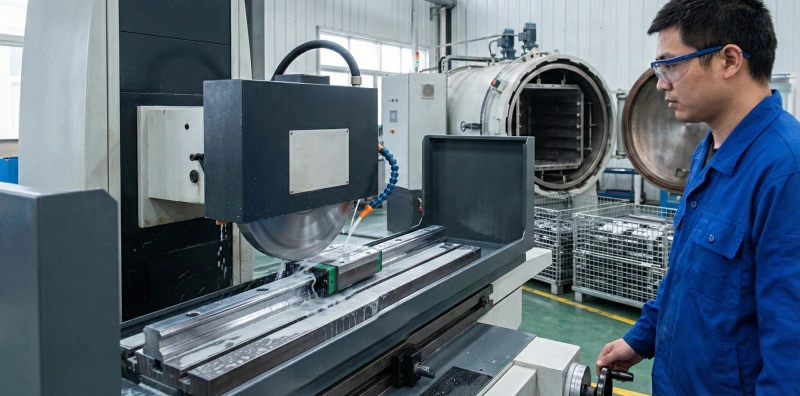

Multi-axis CNC centers machine rail profiles and block cavities to micron-level tolerances, with automated tool compensation ensuring consistent dimensions across production batches.

Heat Treatment & Grinding

Vacuum heat treatment achieves 58-62 HRC hardness, followed by precision surface grinding to 0.2μm Ra finish and straightness within 0.01mm per 300mm length.

Component Assembly

Precision ball bearings assembled into blocks in cleanroom environment, with controlled preload applied according to specifications and lubrication properly distributed.

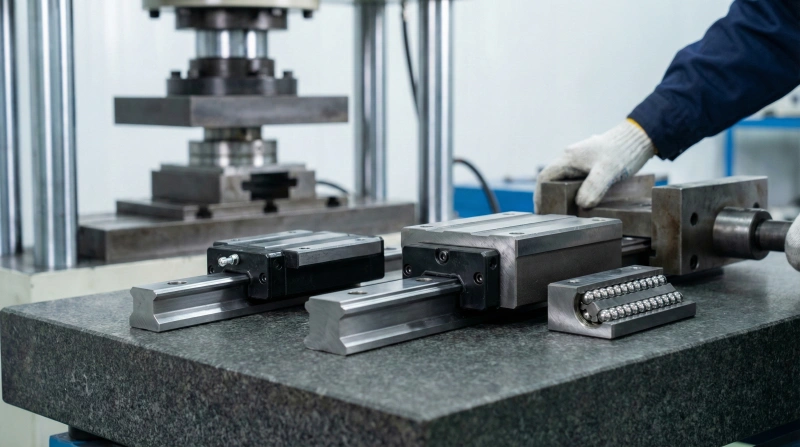

Performance Testing

Assembled guides undergo motion smoothness testing, load capacity verification, and noise level measurement to confirm performance meets rated specifications.

Final Inspection & Packaging

Complete dimensional verification, visual inspection for surface defects, anti-rust treatment application, and secure packaging with protective materials for safe transit.

Comprehensive Quality Assurance System

Multi-stage inspection protocols and precision measurement equipment ensure every guide meets stringent quality standards. Our zero-defect approach prevents problems before they reach your facility.

Incoming Material Inspection

Raw material verification includes chemical composition analysis, hardness testing, and dimensional checks to ensure only qualified steel enters production lines.

Hardness Verification

Post-heat-treatment hardness testing at multiple points confirms uniform 58-62 HRC across entire rail length, guaranteeing wear resistance and load capacity.

Motion Smoothness Test

Every assembled guide undergoes full-stroke motion testing to detect binding, rough spots, or inconsistent resistance that could affect equipment performance.

Dimensional Accuracy Check

CMM measurement verifies all critical dimensions including width, height, mounting hole positions, and block dimensions against engineering drawings.

Geometric Tolerance Inspection

Straightness, parallelism, and perpendicularity measurements ensure rails meet precision specifications required for accurate positioning systems.

Final Random Sampling

Statistical sampling from finished batches undergoes comprehensive re-testing to validate consistent quality throughout entire production run.

Experience the confidence that comes from partnering with a quality-focused manufacturer.

Request Quality DocumentationRequest Your SGR Linear Quote Today

Connect with our technical team to discuss your specific requirements. We provide application-specific recommendations, load calculations, and competitive pricing tailored to your project needs.

Professional Engineering Support: Our experienced mechanical engineers review every inquiry to ensure optimal guide selection, proper sizing, and technical compatibility with your equipment design.