Common Challenges in Mini Guide Rail Procurement

Are you experiencing these frustrations with your current supplier?

Short Lifespan & Easy Wear

Frequent replacement costs and downtime due to premature wear reduce equipment efficiency and increase maintenance expenses significantly

Unstable Precision

Inconsistent accuracy across batches compromises your product quality and leads to assembly difficulties and customer complaints

Jamming & Rough Operation

Slider blocks that stick or move unevenly create noise issues, affect motion control precision, and damage your equipment reputation

Poor Custom Fit

Standard sizes don't match your equipment design requirements, forcing costly modifications or complete redesigns of your assembly

Small-Batch Supply Difficulties

Most suppliers reject small orders or charge premium prices, making prototyping and small-scale production economically unfeasible

Uncertain Delivery & Poor Communication

Unpredictable lead times and lack of technical support delay your project schedules and leave technical questions unanswered

Stop struggling with unreliable suppliers — discover our proven solution

See How We Solve TheseWhy Choose Our Mini Guide Rail Solutions

Engineered solutions that address every challenge you face

Proven Lifespan Testing System

Every batch undergoes 100,000+ cycle endurance testing with documented performance data, ensuring consistent reliability that extends equipment service life by 40%

±0.01mm Precision Grade

CMM-verified dimensional accuracy with comprehensive QC documentation for every production lot, guaranteeing perfect fitment and eliminating assembly frustration

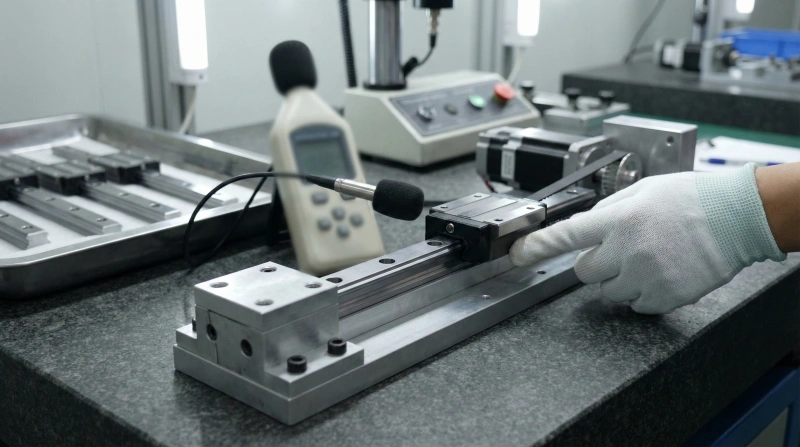

Smoothness Guarantee System

Multi-point friction testing and noise measurement ensure whisper-quiet operation under 45dB, protecting your equipment's premium reputation in the market

Full OEM / ODM Customization

Custom lengths, hole patterns, surface treatments, and slider configurations tailored precisely to your design specs — no compromise on your equipment architecture

Small-Batch Friendly, Fast Delivery

MOQ as low as 10 sets with 3-7 day production cycles for prototypes, enabling rapid product development without inventory risk or excessive capital commitment

Dedicated Engineering Support

One-on-one technical consultation with experienced mechanical engineers who understand motion system design, providing CAD assistance and load calculation support

Experience the difference that precision engineering makes

Request Technical ConsultationMini Guide Rail Product Range

Complete series for every compact motion application

MGN7 Series

Width: 7mm

Rail Length: 50-1000mm

Slider Type: H / C

Applications: Ultra-compact 3D printers, small optical stages, miniature positioning systems

MGN9 Series

Width: 9mm

Rail Length: 100-1500mm

Slider Type: H / C

Applications: Desktop 3D printers, laser engravers, small CNC machines, laboratory equipment

MGN12 Series

Width: 12mm

Rail Length: 150-2000mm

Slider Type: H / C

Applications: Professional 3D printers, pick-and-place machines, medical analyzers

MGN15 Series

Width: 15mm

Rail Length: 200-2500mm

Slider Type: H / C

Applications: Heavy-duty 3D printers, automated assembly lines, precision inspection equipment

MGW Series

Width: 7-15mm

Rail Length: Customized

Slider Type: Wide Block

Applications: Applications requiring enhanced moment load capacity and anti-rotation stability

Custom Solutions

Width: As required

Rail Length: As required

Slider Type: Custom design

Applications: Special projects requiring unique dimensions, mounting patterns, or performance characteristics

Need detailed specifications for your project?

Download Complete Specification Sheet

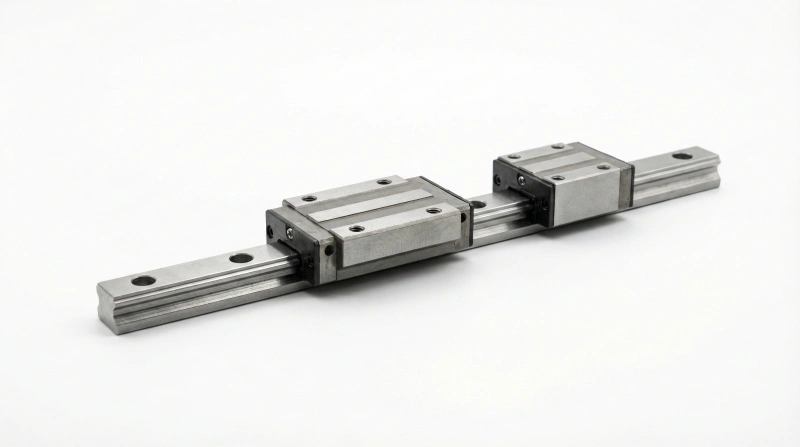

Understanding Mini Guide Rail Working Principles

Master the fundamentals of compact linear motion systems.

Core Structure

Composed of high-hardness steel rails, sliders, and recirculating ball channels. Internal ball circulation converts sliding friction into rolling friction, achieving low resistance and high-precision motion.

Load Bearing

The 4-point contact design absorbs radial, reverse-radial, and lateral loads simultaneously. This ensures stability for high-precision compact equipment under multi-directional forces.

Motion Accuracy

Precision-ground rails combined with high-consistency balls guarantee high repeatability. Ideal for high-speed dispensing, precision handling, and inspection platforms.

Technical Specifications

Detailed dimensional and performance parameters for precise system integration

| Model | Assembly Size | slider size | guide size | weight | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | H1 | N | W | B | B1 | C | L1 | L | G | MXI | H2 | WR | W8 | HR | D | h | d | P | E | slider(g/pc) | guide(kg/meter) | |

| MGN7C MGN7H |

8 | 1.5 | 5 | 17 | 12 | 2.5 | 8 | 13.5 | 22.5 | . | M2*2.5 | 1.5 | 7 | . | 4.8 | 4.2 | 2.3 | 2.4 | 15 | 5 | 10 | 0.22 |

| 13 | 21.8 | 30.8 | 15 | |||||||||||||||||||

| MGN9C MGN9H |

10 | 2 | 5.5 | 20 | 15 | 2.5 | 10 | 18.9 | 28.9 | . | M3*3 | 1.8 | 9 | . | 6.5 | 6 | 3.5 | 3.5 | 20 | 7.5 | 16 | 0.38 |

| 16 | 29.9 | 39.9 | 26 | |||||||||||||||||||

| MGN12C MGN12H |

13 | 3 | 7.5 | 27 | 20 | 3.5 | 15 | 21.7 | 34.7 | . | M3*3.5 | 2.5 | 12 | . | 8 | 6 | 4.5 | 3.5 | 25 | 10 | 34 | 0.65 |

| 20 | 32.4 | 45.4 | 54 | |||||||||||||||||||

| MGN15C MGN15H |

16 | 4 | 8.5 | 32 | 25 | 3.5 | 20 | 26.7 | 42.1 | 4.5 | M3*4 | 3.0 | 15 | . | 10 | 6 | 4.5 | 3.5 | 40 | 15 | 59 | 1.06 |

| 25 | 43.4 | 58.8 | 92 | |||||||||||||||||||

| MGW7C MGW7H |

9 | 1.9 | 5.5 | 25 | 19 | 3 | 10 | 21 | 31.2 | . | M3*3 | 1.85 | 14 | . | 5.2 | 6 | 3.2 | 3.5 | 30 | 10 | 20 | 0.55 |

| 19 | 30.8 | 41 | 29 | |||||||||||||||||||

| MGW9C MGW9H |

12 | 2.9 | 6 | 30 | 21 | 4.5 | 12 | 27.5 | 39.3 | . | M3*3 | 2.4 | 18 | . | 7 | 6 | 4.5 | 3.5 | 30 | 10 | 40 | 1 |

| 23 | 3.5 | 24 | 38.5 | 50.7 | 57 | |||||||||||||||||

| MGW12C MGW12H |

14 | 3.4 | 8 | 40 | 28 | 6 | 15 | 31.3 | 46.1 | . | M3*3.6 | 2.8 | 24 | . | 8.5 | 8 | 4.5 | 4.5 | 40 | 15 | 70 | 1.5 |

| 28 | 45.6 | 60.4 | 105 | |||||||||||||||||||

| MGW15C MGW15H |

16 | 3.4 | 9 | 60 | 45 | 7.5 | 20 | 38 | 54.8 | 5.2 | M4*4.2 | 3.2 | 42 | 23 | 9.5 | 8 | 4.5 | 4.5 | 40 | 15 | 145 | 2.9 |

| 35 | 57 | 73.8 | 215 | |||||||||||||||||||

Application Scenarios

Versatile mini guide rail solutions across diverse industries

Looking for application-specific recommendations?

Consult Our Application EngineersHow to Select the Right Mini Guide Rail

Critical technical factors to consider for optimal performance, stability, and longevity in your equipment.

Load Type Analysis

Determine if the load is radial, reverse-radial, or lateral. Check for moments (yaw/pitch/roll). For off-center loads, wide blocks (MGW) or dual-rail configurations are strongly recommended.

Size & Space Constraints

Common sizes: MGN7, MGN9, MGN12, MGN15. While compact spaces demand smaller rails, always calculate the safety factor (static load rating) to prevent premature fatigue.

Stroke & Speed

Long strokes require strict checking of mounting surface parallelism. High-speed motion (>2m/s) demands enhanced end-seals and more frequent lubrication intervals.

Operating Environment

For dusty, oily, or humid environments (e.g., grinding machines), choose models with reinforced wiper seals and anti-corrosion surface treatments like black chrome or nickel plating.

Mini Guide Rail Lifespan Enhancement Guide

Professional maintenance strategies to maximize service life and performance

Mounting Surface Flatness

Install rails on precision-ground surfaces with flatness tolerance within 0.02mm per 100mm. Surface parallelism between rail mounting positions must not exceed 0.03mm. Poor surface preparation causes uneven load distribution, accelerated wear, and premature failure. Use surface plates or CNC machined bases for critical applications requiring maximum lifespan.

Lubrication Strategy

Apply lithium-based grease (NLGI Grade 2) every 100km of travel or monthly intervals. High-speed applications require synthetic oil lubrication systems with appropriate viscosity ratings. Clean environment operations can extend intervals to 200km. Contaminated environments need protective bellows and frequent relubrication. Proper lubrication reduces friction by 40% and extends L10 lifespan significantly.

Maximum Speed Limits

Respect maximum velocity specifications: MGN7/9 (2m/s), MGN12 (3m/s), MGN15 (4m/s). Exceeding limits causes ball skidding, increased temperature, and rapid raceway wear. High-speed applications demand enhanced lubrication and thermal management. Consider duty cycle and acceleration forces when calculating actual operating speeds for optimal lifespan performance.

Load Distribution Methods

Prevent eccentric loading by maintaining load center alignment with slider centerline. Off-center loads create moment forces that overload ball raceways asymmetrically. Use multiple sliders per rail for heavy or unbalanced loads. Install rails with appropriate spacing to minimize cantilever effects. Proper load distribution prevents premature wear patterns and extends service life by 2-3 times.

Need detailed maintenance procedures for your application?

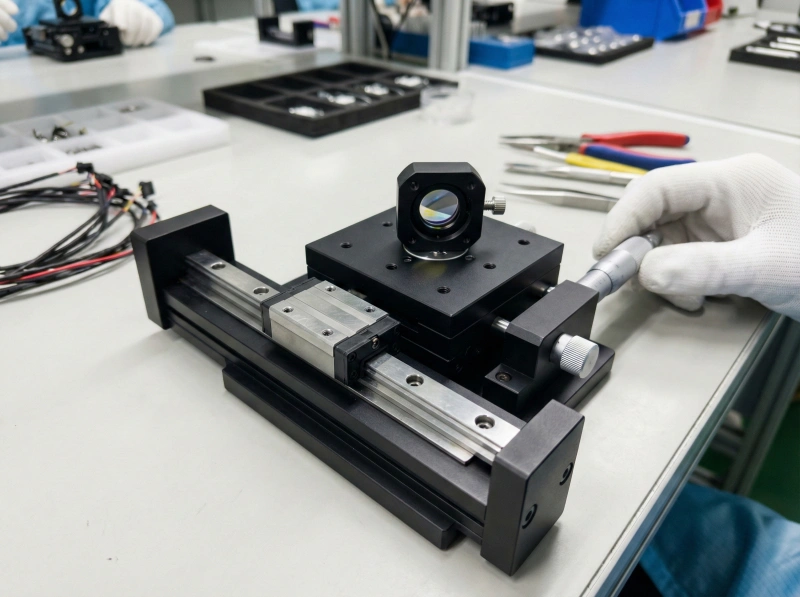

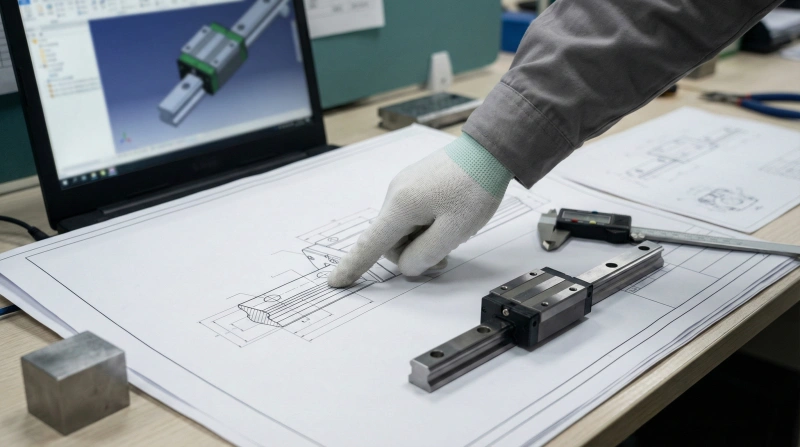

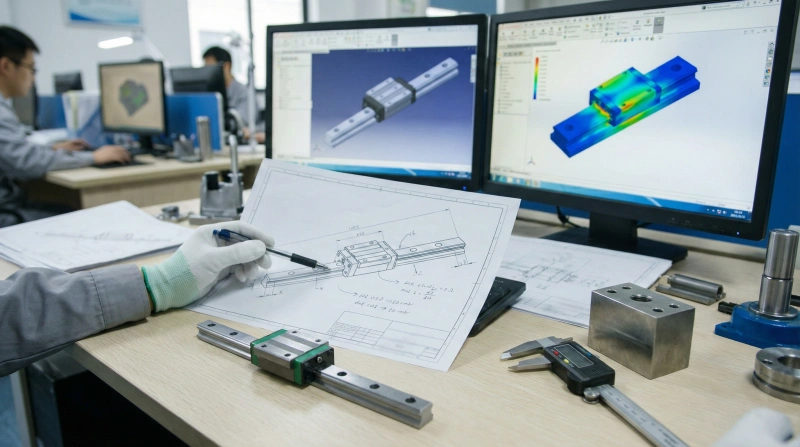

Download Maintenance ManualOEM / ODM Customization Process

Requirements & Drawing

Submit your technical specifications, CAD drawings, and load requirements.

Engineering Analysis

Our engineers perform load calculation, life analysis, and design optimization.

Sampling & Testing

Rapid prototyping followed by dimensional measurement and run-in testing.

Mass Production

High-precision manufacturing on automated CNC lines with strict process control.

Quality Assurance

100% final inspection of dimensions, smoothness, and noise levels before packing.

Delivery & Support

Secure anti-rust packaging, global logistics, and lifetime technical support.

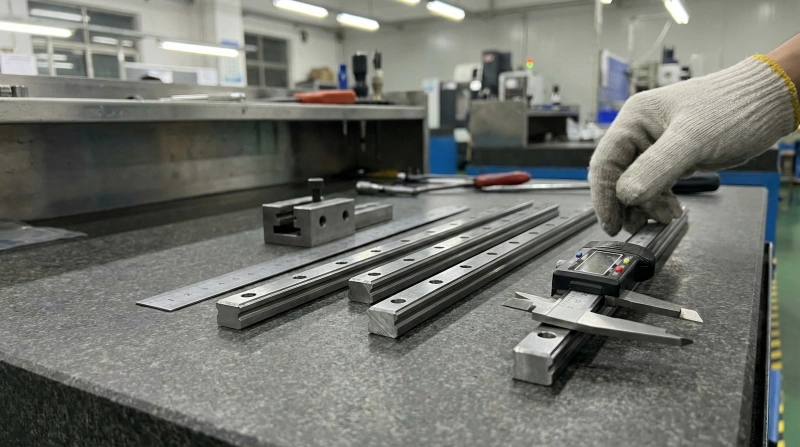

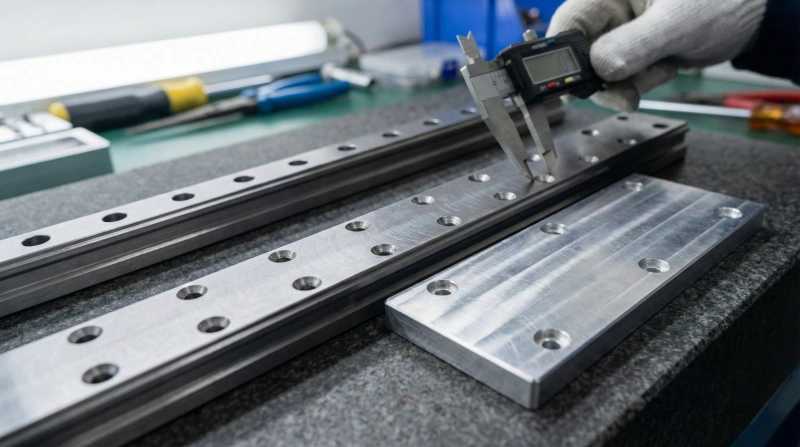

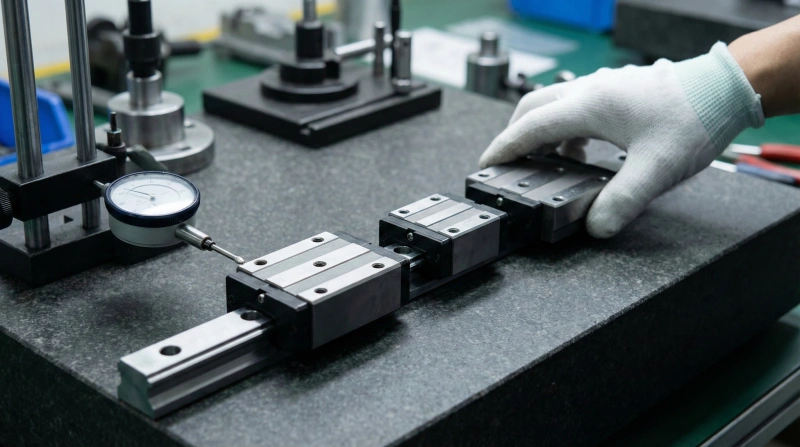

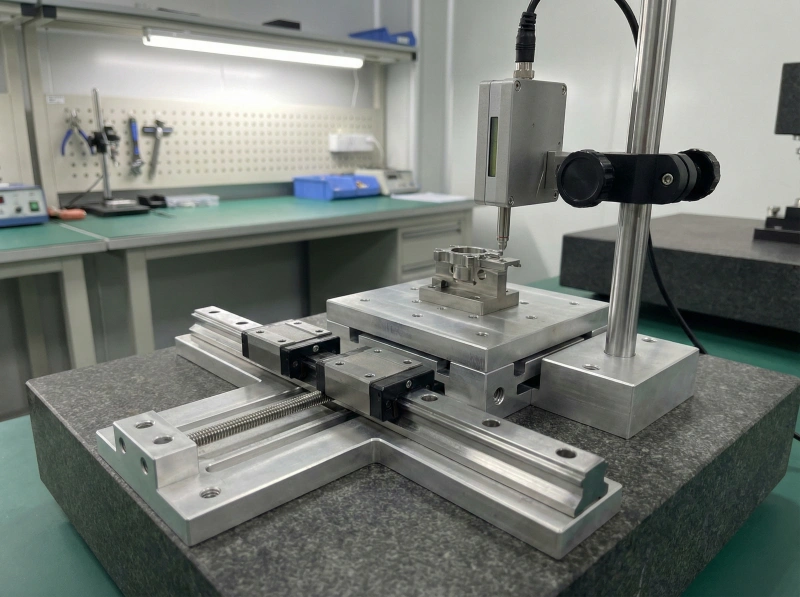

Quality Control System

Rigorous inspection protocols at every stage ensure consistent precision, low noise, and extended service life for every rail we deliver.

Precision Dimensional Inspection

CMM and video measuring systems verify critical dimensions, straightness, and parallelism batch by batch to ensure assembly consistency.

Noise & Smoothness Testing

We rigorously test running noise and ball circulation smoothness to prevent sticking or abnormal sounds that could cause rework.

Hardness & Heat Treatment

Verification of post-heat-treatment hardness ensures consistent wear resistance and prevents lifespan variations between batches.

Surface Finish Inspection

Rail surface roughness directly impacts running resistance and life. We strictly control machining texture and polishing consistency.

Assembly & Preload Control

Precise control of slider preload class strikes the perfect balance between "zero clearance" and "low friction" to avoid overheating.

Traceability & Batch Records

Every batch is recorded with inspection reports and production lot numbers, supporting full after-sales traceability and project acceptance.

Customer Testimonials

Trusted by engineers and manufacturers worldwide for quality and reliability

"These MGN12 rails transformed our 3D printer reliability. Smooth operation, zero backlash, and the custom length cutting saved us significant assembly time. Technical support was exceptional throughout the selection process."

"Outstanding quality mini guide rails for our medical analysis equipment. Consistent precision across batches and excellent small-quantity support for prototyping. Delivery times are reliable and communication is professional."

"Perfect solution for our miniature automation systems. The custom hole pattern service eliminated adapter plates from our design. Pricing is competitive and the engineering team understands motion control applications thoroughly."

"Reliable supplier for our optical positioning stages. Documentation is comprehensive, quality control is rigorous, and they accommodate our specific accuracy requirements. The nickel-plated option works perfectly in our clean room environment."

Join hundreds of satisfied customers worldwide

Read More Success StoriesGet Your Custom Mini Guide Rail Quote

Fill out the form below and our engineering team will respond within 24 hours with a detailed quotation and technical recommendations

Why Contact Us?

24-Hour Response Time

Fast quotations with detailed technical analysis

Expert Engineering Support

Professional guidance for optimal selection

Flexible Customization

Small batches and OEM/ODM services available

Quality Assurance

100% inspection with comprehensive documentation

Prefer direct communication?

Ready to Build Your Compact Motion System with Precision?

Experience professional engineering support, reliable quality, and fast delivery for your mini guide rail requirements. Let's bring your precision motion project to life with our proven solutions.