Challenges That Impact Your Production Efficiency

Manufacturing teams worldwide face critical issues with linear guide systems that directly affect output quality, equipment lifespan, and operational costs

Inconsistent Accuracy

Dimensional variations and positioning errors compromise product quality, leading to increased rejection rates and costly rework that drains your profitability

Premature Wear & Failure

Rails that wear out faster than expected create unplanned downtime, emergency maintenance costs, and production schedule disruptions that impact your delivery commitments

Poor Concentricity Control

Alignment issues between rail and carriage cause uneven load distribution, accelerating component degradation and reducing overall system reliability

Excessive Noise & Vibration

Rough operation creates workplace noise pollution, indicates friction problems, and signals imminent failure requiring immediate attention and unplanned intervention

Unreliable Lead Times

Delayed deliveries stall your production schedules, miss critical project milestones, and damage your reputation with customers waiting for finished products

Lack of Technical Support

Without expert guidance on rail selection and system design, you risk choosing incorrect specifications that lead to performance issues, compatibility problems, and wasted investment

Stop struggling with unreliable guide rail systems that compromise your production quality

Discover Our SolutionsHow We Eliminate These Challenges

Our advanced manufacturing processes and quality control systems directly address each pain point, delivering guide rails that exceed industry standards and customer expectations

High-Precision Grinding Equipment

Our CNC grinding machines maintain tolerances within ±2μm, ensuring every rail delivers consistent accuracy that keeps your production within specification and reduces defect rates to near zero

Induction Hardening Process

High-frequency hardening creates a hardened layer of HRC58-62, dramatically extending operational life to over 50,000km of travel while maintaining smooth performance throughout the rail's lifetime

Advanced Measurement Systems

Three-coordinate measuring machines verify every dimensional parameter, guaranteeing perfect concentricity and parallelism that eliminate alignment issues and ensure optimal load distribution across all contact surfaces

Optimized Seal Design

Multi-layer dust protection shields and advanced seal geometry prevent contamination ingress while maintaining low friction, delivering whisper-quiet operation and extending maintenance intervals by up to 300%

Integrated Supply Chain

Our in-house production facility and strategic material partnerships ensure consistent 7-14 day delivery windows, keeping your projects on schedule and eliminating the uncertainty of extended lead times

Dedicated Engineering Team

Our application engineers provide complimentary technical consultation, calculating load requirements, recommending optimal rail series, and validating your design choices to ensure perfect specification match from the start

Experience the difference that precision manufacturing and expert support deliver

Request Technical ConsultationComplete Linear Guide Rail Series

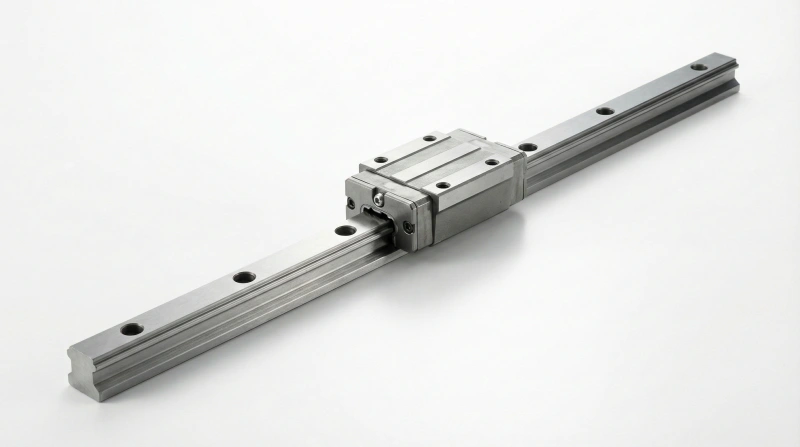

From compact miniature systems to heavy-duty industrial applications, our comprehensive product range delivers precision motion solutions for every manufacturing requirement

H Series - Heavy Duty

Engineered for maximum load capacity and rigidity, the H Series handles demanding applications where high moment loads and extended service life are critical requirements

- Load capacity up to 85kN

- Four-direction equal load design

- Ideal for large CNC machines

E Series - Enhanced Performance

Balanced design offering optimal combination of load capacity, precision, and smooth operation for general industrial automation and precision machinery applications

- Versatile medium load capacity

- Excellent cost-performance ratio

- Suitable for robotic systems

Q Series - Quiet Operation

Advanced ball circulation design and optimized raceway geometry deliver ultra-quiet performance for environments where noise reduction is a priority consideration

- Industry-leading low noise levels

- Smooth motion control

- Perfect for medical equipment

Narrow Type - Space Saving

Compact width design maximizes space utilization in tight installations while maintaining precision performance and reliability for space-constrained equipment designs

- Reduced mounting width

- High rigidity despite compact size

- Ideal for multi-axis systems

Wide Type - Superior Stability

Extended width configuration provides exceptional moment rigidity and stability for applications requiring superior resistance to overturning moments and offset loads

- Maximum moment load capacity

- Enhanced anti-vibration properties

- Best for gantry systems

Miniature Series - Precision Micro Motion

Ultra-compact design for small-scale precision applications, delivering high accuracy and smooth operation in minimal footprint for specialized instrumentation and testing equipment

- Rail width from 7mm

- Precision grade up to P class

- Perfect for optical devices

Not sure which series fits your application? Our engineers will help you select the perfect solution

Request Product Selection GuideUnderstanding Linear Guide Rail Technology

Master the fundamental principles that make linear guide rails essential for precision motion control in modern manufacturing systems

Load Support Function

Distributes weight and forces across multiple contact points, preventing deflection and maintaining consistent positioning accuracy under dynamic loading conditions.

Precision Motion Guidance

Constrains movement to a single axis while resisting lateral forces, ensuring straight-line travel without deviation or play that compromises machining precision.

Ultra-Low Friction Design

Rolling element design minimizes resistance to motion, reducing drive force requirements by up to 95% compared to sliding contact systems.

Superior to Linear Shafts

Guide rails provide significantly higher moment load capacity through their raceway design, handling overturning moments that would cause shafts to bind.

Four-Direction Load Distribution

Four-row ball configuration distributes loads equally in all directions, enabling guide rails to support 3-5x higher loads than equivalent diameter systems.

Critical Industrial Applications

Essential for CNC machining centers, laser cutting systems, industrial robots, and automated assembly lines requiring positional accuracy of ±5μm.

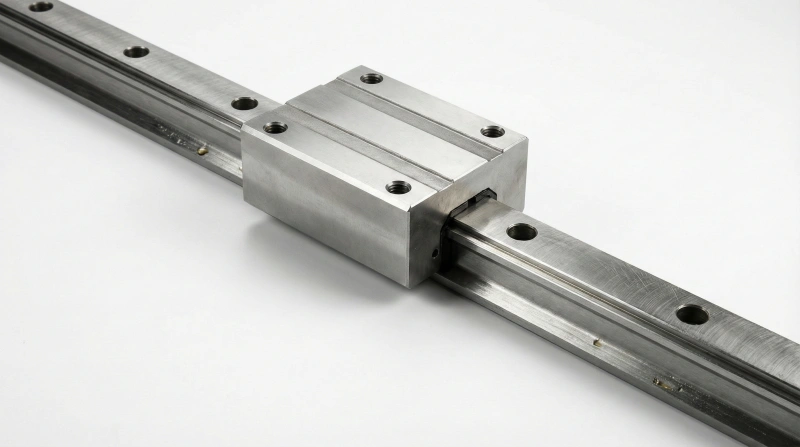

Linear Guide Rail Structure Explained

Six critical components working together to deliver precision motion control and extended service life in demanding industrial applications

Precision Rail Track

Hardened steel foundation with four precision-ground raceway grooves machined to ±2μm tolerance, maintaining accuracy through millions of cycles.

Slider Block Assembly

Carriage with matched raceway geometry distributes loads evenly across ball contact points for smooth motion and easy mounting integration.

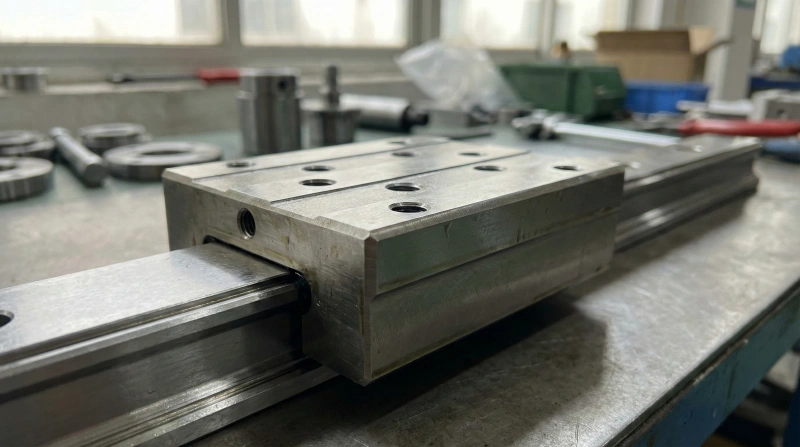

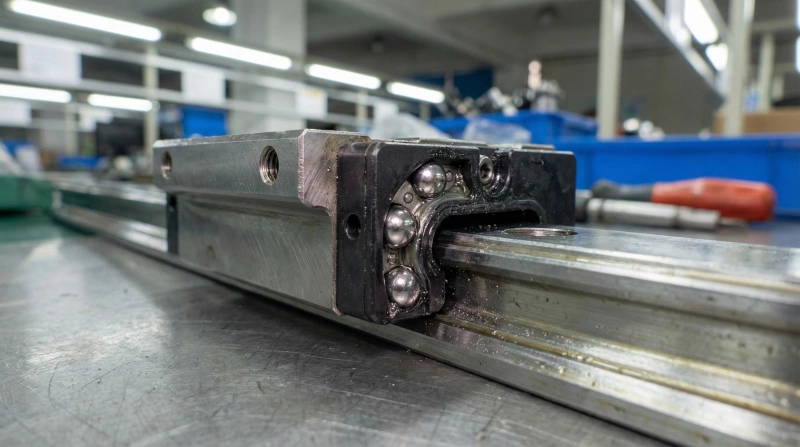

Ball Circulation Path

Continuous rolling element circulation reduces friction by 95% while supporting high loads, enabling unlimited travel length with consistent performance.

Multi-Layer Sealing

Advanced seal geometry prevents contamination ingress while retaining lubrication, extending maintenance intervals by 300% in harsh environments.

Raceway Grooves

Four-row raceway design distributes loads in all directions, providing superior rigidity and 3-5x higher load capacity than shaft systems.

Preload Mechanism

Precise preload adjustment eliminates clearance and maintains positional accuracy, ensuring zero backlash for bidirectional precision motion control.

Technical Specifications

Detailed dimensional and performance parameters for precise system integration

| Model | Size | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | W | N | H1 | L | B*C | M*1 | L1 | H2 | G | WR | HR | P | dxDxh | Weight/meter | |

| HDW15CA | 24 | 47 | 16 | 4.6 | 66 | 38*30 | M5*8 | 40 | 4.3 | 5 | 15 | 14 | 60 | 4.5x7.5x5.3 | 1.5kg |

| HDW20CA | 30 | 63 | 21.5 | 5 | 78 | 53*40 | M6*9 | 48.8 | 7 | 15.6 | 20 | 18 | 60 | 6x9.5x8.5 | 2.7kg |

| HDW25CA | 36 | 70 | 23.5 | 7 | 88 | 57*45 | M8*12 | 57 | 7.8 | 15.6 | 23 | 22 | 60 | 7x11x9 | 3.6kg |

| HDW30CA | 42 | 90 | 31 | 9 | 109 | 72*52 | M10*12 | 72 | 7 | 15.6 | 28 | 26 | 80 | 9x14x12 | 5.2kg |

| HDW35CA | 48 | 100 | 33 | 9.5 | 109 | 82*62 | M10*13 | 80 | 8 | 15.6 | 34 | 29 | 80 | 9x14x12 | 7.2kg |

| HDW45CA | 60 | 120 | 37.5 | 14 | 138 | 100*80 | M12*15 | 105 | 8.5 | 16 | 45 | 38 | 105 | 14x20x17 | 12.3kg |

Comprehensive Quality Control System

Every linear guide rail undergoes rigorous multi-stage inspection protocols ensuring dimensional accuracy and reliability

Full Dimensional Inspection

Precision measurement of all critical dimensions including rail width, height, raceway position, and mounting hole locations using calibrated instruments.

CMM Coordinate Measurement

Three-coordinate measuring machines verify geometric accuracy including straightness, parallelism, and perpendicularity to micron-level precision.

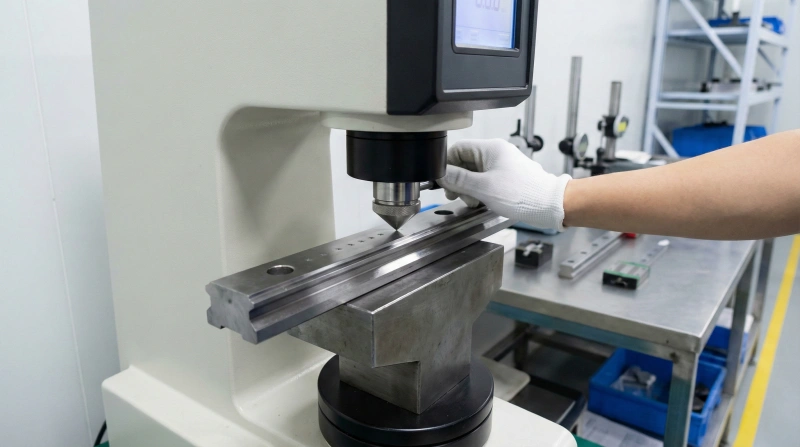

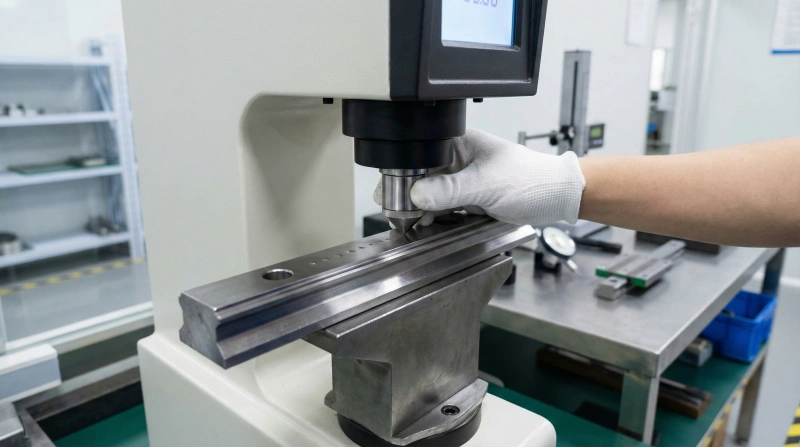

Hardness Testing

Rockwell hardness verification at multiple locations across raceway surfaces confirms heat treatment effectiveness and uniformity.

Surface Finish Analysis

Raceway surface roughness measured to verify grinding quality meets Ra 0.2μm specification, guaranteeing smooth ball rolling motion and minimal friction.

Endurance Life Testing

Sample rails undergo accelerated life testing under maximum rated loads and speeds, validating design life calculations and confirming L50 life ratings.

Seal Performance Validation

Dust ingress testing and seal integrity verification ensure protection systems maintain effectiveness throughout operational life.

Comprehensive Customization Options

Tailored manufacturing capabilities ensure every linear guide rail perfectly matches your unique application requirements

Custom Length

Any rail length from 100mm to 6000mm manufactured to your exact specifications, eliminating field cutting and ensuring optimal fit.

Special Hole Patterns

Modified mounting hole spacing and positioning to match existing equipment footprints, simplifying retrofits and upgrades.

Non-Standard Dimensions

Custom rail width, height, or cross-section profiles engineered for unique load distribution requirements or space constraints.

Enhanced Hardness

Increased surface hardness specifications up to HRC65 for extreme wear environments, extending service life in abrasive conditions.

Precision Machining

Additional machined surfaces, reference edges, or datum features added to rails for simplified alignment and assembly.

Special Lubrication

Custom lubrication systems including food-grade greases, high-temperature compounds, or solid lubricants for specialized environments.

Seamless Procurement Process

From initial inquiry to delivery and beyond, our streamlined process ensures you receive the right linear guide rail solution on time and within budget

Technical Consultation

Share your application requirements, load specifications, and operating conditions. Our engineers analyze your needs and recommend optimal rail series, accuracy grade, and configuration to ensure performance and cost-effectiveness.

Professional Selection Guidance

Receive detailed technical recommendations including load calculations, life expectancy analysis, and mounting suggestions. We provide CAD models and dimensional drawings to facilitate your design integration and verification.

Transparent Quotation

Receive comprehensive pricing covering rails, carriages, and accessories with clear lead times and shipping options. Volume discounts and flexible payment terms available for large projects or ongoing supply agreements.

Quality-Controlled Manufacturing

Production follows strict quality protocols with multi-stage inspection. Receive progress updates and inspection reports throughout manufacturing. Final testing confirms all specifications before packaging for shipment.

Delivery & After-Sales Support

Secure packaging ensures damage-free delivery with full documentation including inspection certificates and installation guides. Technical support continues post-delivery with troubleshooting assistance and maintenance recommendations.

Ready to start your linear guide rail procurement?

Begin Your ProjectTrusted by Industry Leaders Worldwide

Manufacturing professionals across diverse industries rely on our linear guide rails for critical motion control applications

"We've retrofitted twelve CNC machines with these guide rails over the past two years. The positioning accuracy improvement was immediately measurable - we reduced our scrap rate by 40% on tight-tolerance aerospace components. Lead times are reliable and technical support is excellent."

"Our automated assembly line runs 24/7 and these guide rails have proven incredibly durable. After 18 months of continuous operation, we're seeing no degradation in performance. The quiet operation is a bonus - our facility noise levels dropped significantly. Excellent value for high-volume production."

"We needed custom-length rails with special mounting patterns for a robotic welding cell. The engineering team provided detailed load calculations and recommended the perfect specification. Delivery was on schedule and the rails dropped right in - saved us considerable integration time."

"Running high-speed packaging lines for pharmaceutical products demands reliability. These guide rails maintain consistent performance through millions of cycles. The sealed design handles our washdown requirements perfectly. Quality documentation is thorough - important for our regulatory compliance."

Join hundreds of satisfied customers achieving better performance with our guide rails

Start Your Success Story