High-Precision Linear Shaft Supplier for Automation Systems

Professional Linear Shaft Solutions | Custom Machining Support | Compatible with Multi-Brand Guide Rails & Linear Components

Common Challenges When Sourcing Linear Shafts

Many buyers face critical issues that compromise their automation systems. Identify these problems before they impact your production efficiency and equipment lifespan.

Lack of Technical Understanding

Suppliers without engineering expertise cannot guide you on proper shaft selection, leading to compatibility issues and system failures in your automation equipment.

Poor Straightness Tolerance

Substandard straightness causes bearing seizure, uneven wear, and positioning errors that directly compromise your precision requirements and production quality.

Chrome Plating Peeling

Low-quality chrome plating flakes off quickly, exposing the shaft to corrosion and accelerating wear, resulting in frequent replacements and unexpected downtime costs.

Inconsistent Dimensional Tolerance

Unstable manufacturing processes create diameter variations that prevent proper bearing fitment, causing excessive play or binding that ruins operational smoothness.

Bearing & Housing Incompatibility

Mismatched components from different suppliers create assembly difficulties and performance issues, forcing you to source from multiple vendors and increasing project complexity.

Slow Delivery & No Small Batch Options

Long lead times and high MOQs stall your prototyping and testing phases, delaying product development cycles and forcing you to overstock inventory unnecessarily.

Don't let these problems derail your automation projects.

Discover Our SolutionsWhy Leading Manufacturers Choose YiCheng Linear Shafts

Every challenge has a precision-engineered solution. Our technical expertise and manufacturing capabilities directly address the pain points that compromise your automation systems.

Expert Engineering Team Support

Our mechanical engineers provide in-depth technical consultation throughout your project lifecycle, ensuring optimal shaft specifications match your load requirements, travel distance, and environmental conditions for peak system performance.

Superior Chrome Hardness HRC58-62

Advanced electroplating technology delivers consistent chrome layer hardness meeting international standards, significantly extending bearing life and maintaining smooth motion even under continuous high-load operations in industrial environments.

Precision Grinding to 0.01-0.03mm Straightness

State-of-the-art grinding machines and strict quality protocols guarantee exceptional straightness tolerance, eliminating bearing friction issues and ensuring smooth linear travel that maintains positioning accuracy across your automation system's full stroke length.

ISO Standard Dimensional Accuracy

Certified manufacturing processes and advanced measurement equipment ensure diameter tolerances consistently meet g6/h6 standards, providing reliable bearing fits and interchangeability that streamlines your assembly process and reduces quality control issues.

Complete Linear Motion System Integration

One-stop solution for linear shafts, matched bearing housings, and compatible guide rails eliminates component compatibility concerns, saves procurement time, and reduces your vendor management overhead while ensuring optimal system performance from day one.

24-Hour Quick Quote & Flexible MOQ

Rapid response system provides detailed quotations within one business day, while our flexible minimum order quantities support prototype development and small-scale production runs, accelerating your product development timeline without inventory burden.

Experience the YiCheng advantage in precision linear motion.

Request Technical ConsultationComprehensive Linear Shaft Product Range

From standard cylindrical shafts to specialized hollow designs, we manufacture a complete spectrum of linear motion solutions that meet diverse automation requirements across industries.

Standard Cylindrical Linear Shaft

General-purpose hardened steel shafts for basic linear motion applications, offering excellent cost-performance balance for light to medium-duty automation equipment with reliable dimensional stability.

Material: SUJ2 | Surface: Induction Hardened HRC60±2

Precision Ground Linear Shaft

Ultra-smooth surface finish achieved through multi-stage grinding processes, ideal for high-precision CNC machines, measuring instruments, and semiconductor equipment demanding minimal friction and exceptional straightness.

Straightness: ≤0.01mm/1000mm | Surface Roughness: Ra 0.2μm

Hard Chrome Plated Linear Shaft

Premium chrome-plated surface delivers superior wear resistance and corrosion protection, extending operational lifespan in harsh environments including humid conditions, chemical exposure, and continuous-duty applications.

Chrome Hardness: HRC58-62 | Plating Thickness: 15-25μm

Hollow Linear Shaft

Weight-optimized design reduces moving mass for faster acceleration and lower energy consumption, perfect for high-speed pick-and-place systems, robotic arms, and applications requiring cable or fluid passage through the shaft.

Wall Thickness: 3-8mm | Weight Reduction: Up to 40%

Linear Bearing Compatible Shaft

Precisely engineered to match LM, LME, and other standard linear bearing series specifications, ensuring optimal clearance, smooth rolling action, and extended bearing life through perfect geometric compatibility.

Compatible with: LM Series, LME Series, Standard Sizes

Shaft with Bearing Housing Assembly

Pre-assembled shaft and bearing housing units arrive ready for installation, dramatically reducing assembly time and eliminating alignment challenges while ensuring factory-tested performance from the start.

Installation Time: Reduced by 70% | Pre-tested & Aligned

Can't find the exact specification? We customize linear shafts to your requirements.

Explore Custom OptionsLinear Shaft Fundamentals: Technical Knowledge Hub

Understanding the core principles behind linear shaft design, manufacturing, and application empowers you to make informed decisions that enhance your automation system's performance and longevity.

Linear Shaft Definition & Structure

A linear shaft is a precision-machined cylindrical rod that serves as the guiding element in linear motion systems. Working in conjunction with linear bearings, it enables smooth, accurate, and repeatable straight-line motion essential for automation equipment.

- Core Material: High-carbon chromium bearing steel (SUJ2/52100) provides exceptional hardness and wear resistance through heat treatment, ensuring long-term dimensional stability under load.

- Surface Layer: Grinding and optional chrome plating create the ultra-smooth, hardened surface that minimizes friction with bearing balls while resisting environmental corrosion.

- Geometric Precision: Strict control of straightness, cylindricity, and surface roughness guarantees consistent bearing contact and smooth motion throughout the shaft's length.

Surface Treatment Impact on Lifespan

Surface treatment directly determines your linear shaft's operational lifespan and reliability. The right treatment choice matches your application's environmental conditions and performance demands.

- Hard Chrome Plating: Increases surface hardness to HRC58-62, dramatically extending bearing life by 3-5 times while providing excellent rust protection for humid or corrosive environments.

- Precision Grinding: Reduces surface roughness to Ra 0.2μm or better, minimizing bearing friction and noise while improving positioning repeatability in high-precision applications.

- Combined Treatment: Chrome plating followed by final grinding delivers both maximum hardness and smoothness, representing the premium solution for demanding continuous-operation environments.

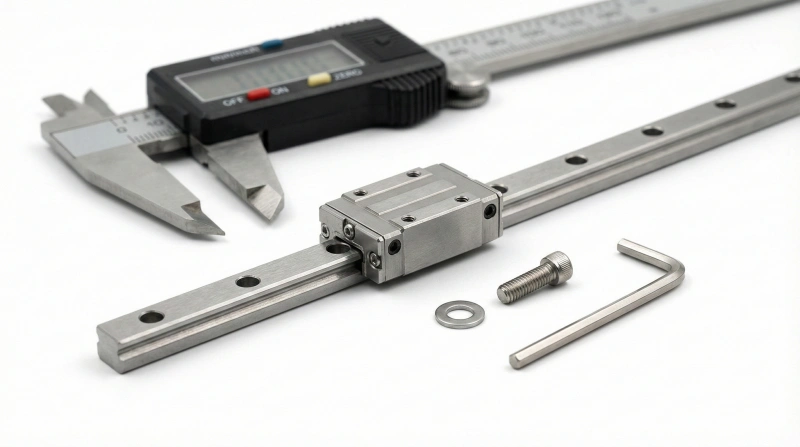

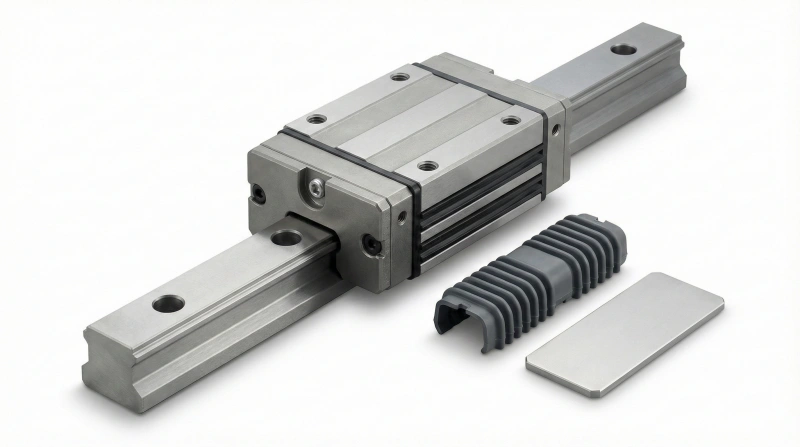

Linear Shaft vs. Guide Rail Systems

Understanding when to use linear shafts versus guide rails prevents costly specification errors and ensures optimal system performance for your specific application requirements.

- Linear Shafts: Excel in compact spaces with moderate loads, offering simpler installation, lower cost, and excellent performance for general automation equipment, 3D printers, and light CNC applications.

- Guide Rails: Handle higher loads and moments with greater rigidity, making them ideal for heavy machining centers, large gantry systems, and applications requiring multiple carriages on one rail.

- Hybrid Solutions: Many advanced systems combine both technologies—guide rails for primary load-bearing and linear shafts for auxiliary guidance, maximizing performance while controlling costs.

Common Application Industries

Linear shafts power precision motion across diverse industrial sectors, each with unique performance requirements that demand specific shaft characteristics and configurations.

- Automation Equipment: Assembly lines, pick-and-place robots, and conveyor systems rely on linear shafts for consistent positioning and rapid cycle times in manufacturing environments.

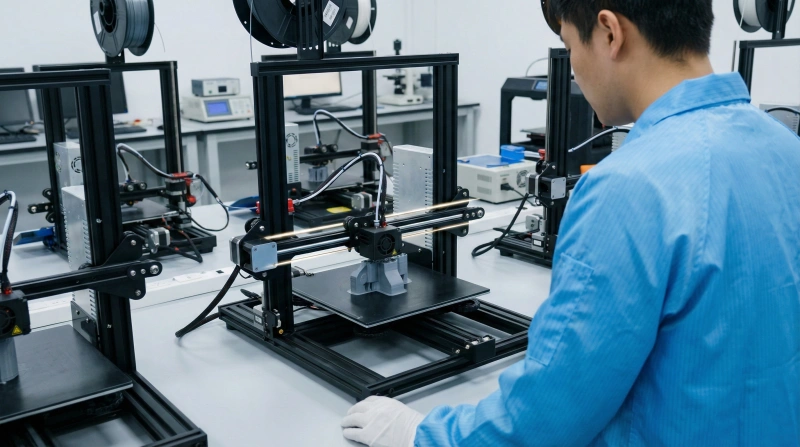

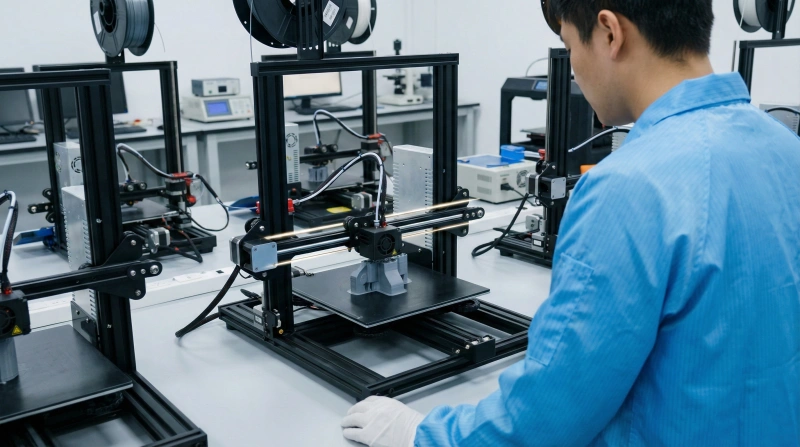

- 3D Printing & Prototyping: Precision motion platforms use hardened shafts to maintain dimensional accuracy throughout long print jobs, ensuring layer consistency and final part quality.

- Packaging Machinery: High-speed filling, labeling, and cartoning equipment depends on chrome-plated shafts to withstand continuous operation and resist contamination from product residues.

- Medical Equipment: Diagnostic devices, laboratory automation, and surgical robots require ultra-smooth shafts that deliver silent operation and exceptional positioning repeatability for patient safety.

Need help selecting the right linear shaft for your application?

Talk to Our EngineersFlexible Customization Capabilities

Transform standard linear shafts into precision-engineered solutions tailored to your unique automation challenges through our comprehensive custom machining services.

Non-Standard Length Cutting

Precision cutting to your exact length requirements from 100mm to 6000mm, eliminating material waste and reducing your secondary machining operations while maintaining strict perpendicularity and surface finish standards.

Custom Hole Drilling

Through-holes, blind holes, and tapped holes machined to your specifications for cable routing, lubrication passages, or mounting purposes, with precise positioning tolerances ensuring perfect alignment with your assembly requirements.

Flat Surface Machining

Precision-milled flats for anti-rotation features, sensor mounting surfaces, or alignment references, machined parallel or perpendicular to shaft axis with specified angular tolerances and surface finish requirements.

Special Surface Coatings

Alternative surface treatments beyond standard chrome plating including nickel plating for food-grade applications, black oxide for optical systems, or specialized coatings for extreme temperature or chemical resistance requirements.

Bearing & Housing Integration

Complete linear motion assemblies with pre-installed bearings, housings, and support units configured to your specifications, arriving fully tested and ready for immediate installation into your automation system.

Large Volume OEM Programs

Dedicated production runs with your private labeling, custom packaging, and quality documentation tailored to your distribution requirements, supported by stable pricing agreements and guaranteed delivery schedules for high-volume manufacturing needs.

Transform your design concept into reality with our engineering support.

Start Custom ProjectStreamlined OEM & ODM Service Process

From initial concept to final delivery, our systematic six-phase approach ensures your custom linear shaft project progresses smoothly with complete transparency and quality assurance at every milestone.

Engineering Drawing Review

Submit your technical drawings and specifications for comprehensive engineering review, identifying potential manufacturability issues and optimization opportunities before production begins.

Material & Specification Confirmation

Collaborate with our engineers to select optimal materials, tolerances, and surface treatments that balance performance requirements with cost-effectiveness for your application.

Process Planning & Validation

Develop detailed manufacturing process plans including machining sequences, coating procedures, and quality checkpoints, validated through first article inspection and approval.

Prototype Development

Manufacture sample prototypes for your evaluation and testing, ensuring all specifications meet your requirements before committing to full-scale production runs.

Volume Production

Execute full-scale manufacturing under strict quality control protocols with in-process inspections, comprehensive documentation, and real-time production status updates.

Packaging & Logistics

Custom packaging designed to protect your linear shafts during transit, coupled with reliable international shipping arrangements and complete traceability documentation.

Ready to launch your custom linear shaft project with confidence?

Initiate OEM PartnershipLinear Shaft Quality Indicators: Straightness & Lifespan

Understanding the critical relationship between straightness tolerance and operational lifespan empowers you to specify the right quality grade and avoid premature failures that compromise your automation system.

How Straightness Affects Bearing Performance

Straightness tolerance is the most critical geometric parameter determining linear shaft quality, as even minor deviations create uneven bearing contact pressure that accelerates wear and compromises positioning accuracy.

- Bearing Load Distribution: Perfectly straight shafts distribute bearing loads evenly across all ball elements, while bent shafts concentrate forces on specific points, dramatically increasing contact stress and accelerating ball wear.

- Friction and Smoothness: Straightness deviations beyond 0.03mm per meter cause noticeable resistance variations during bearing travel, manifesting as jerky motion, increased friction, and positioning repeatability errors in precision applications.

- System Binding Risk: Severely bent shafts can cause bearing seizure in multi-shaft parallel systems where geometric misalignment prevents smooth simultaneous motion, potentially damaging both shafts and bearings.

Chrome Plating Quality and Durability

Hard chrome plating serves as the critical protective barrier between bearing elements and the shaft core, with plating quality directly determining operational lifespan under continuous duty cycles.

- Hardness Requirements: HRC58-62 chrome hardness provides optimal resistance to bearing ball indentation and abrasive wear, while softer platings below HRC55 deteriorate rapidly under continuous rolling contact stress.

- Adhesion and Peeling: Poor electroplating processes create weak bonding between chrome layer and base material, resulting in flaking that exposes bare steel to corrosion and creates abrasive particles that destroy bearing seals.

- Thickness Consistency: Uniform 15-25μm plating thickness across the entire shaft length ensures consistent bearing clearances and wear characteristics, while thickness variations create performance inconsistencies and premature local failures.

Common Issues with Low-Quality Shafts

Substandard linear shafts exhibit characteristic failure modes that lead to costly downtime and complete system rebuilds, making initial quality investment critical for long-term reliability.

- Chrome Layer Flaking: Inadequate plating adhesion causes visible chrome peeling that generates abrasive debris, destroys bearing seals, and exposes steel substrate to rapid oxidation in humid environments.

- Excessive Shaft Bowing: Improper heat treatment or inadequate straightening results in visible shaft curvature that binds bearings, causes uneven wear patterns, and creates positioning errors in precision motion systems.

- Bearing Seizure: Combination of poor straightness and soft chrome plating creates high friction points where bearings bind and lock, potentially causing motor overload, position loss, or catastrophic mechanical damage.

Quality Inspection Methods

Professional linear shaft manufacturers employ sophisticated measurement techniques to verify geometric accuracy and surface quality, ensuring specifications meet international standards before shipment.

- Straightness Measurement: Precision dial indicators or laser measurement systems detect shaft bow across multiple angular orientations, identifying deviations as small as 0.005mm over 1000mm length spans.

- Surface Quality Testing: Contact profilometers measure surface roughness to verify Ra values, while visual inspection under magnification detects chrome plating defects like pitting, peeling, or contamination.

- Dimensional Verification: Calibrated micrometers and ring gauges confirm diameter tolerances meet g6 or h6 standards throughout shaft length, ensuring proper bearing clearances for smooth operation and adequate load capacity.

Questions about quality specifications for your application?

Consult Our EngineersLinear Shaft Applications Across Industries

From precision medical devices to heavy industrial automation, linear shafts enable reliable motion control in diverse applications where performance, accuracy, and durability are mission-critical requirements.

Automation Equipment

Assembly lines, pick-and-place systems, and industrial robots depend on precision linear shafts to achieve consistent positioning accuracy, rapid cycle times, and maintenance-free operation throughout millions of motion cycles in demanding production environments.

CNC Machines & Machining Centers

Multi-axis CNC equipment utilizes chrome-plated linear shafts for auxiliary axes and tool changers, delivering smooth motion under heavy loads while maintaining positioning repeatability essential for precision metal cutting and surface finishing operations.

Medical & Laboratory Devices

Diagnostic imaging systems, laboratory automation, and surgical robots require ultra-smooth linear motion with minimal noise and exceptional positioning accuracy, making precision-ground shafts with strict straightness tolerances essential for patient safety and reliable test results.

Logistics & Material Handling

Automated warehouses, sorting systems, and conveyor technologies employ linear shafts in carriage guidance systems that handle continuous operation demands, providing cost-effective motion solutions that balance performance with the high volume requirements of modern distribution centers.

3D Printing & Rapid Prototyping

Additive manufacturing platforms utilize hardened linear shafts to maintain dimensional accuracy throughout extended print cycles, with low friction characteristics enabling faster travel speeds and quieter operation critical for desktop and professional 3D printing applications.

Packaging & Filling Machinery

High-speed packaging lines leverage chrome-plated shafts to withstand continuous duty cycles in environments exposed to moisture, temperature fluctuations, and product contamination, where corrosion resistance and wear durability directly impact production uptime and maintenance costs.

Don't see your industry listed? We serve diverse applications worldwide.

Discuss Your ApplicationComprehensive Quality Control System

Multi-stage inspection protocols ensure every linear shaft meets strict international standards before shipment, protecting your production schedules from costly quality failures and unexpected downtime.

Material Incoming Inspection

Raw steel materials undergo rigorous chemical composition analysis and hardness verification before production authorization, ensuring consistent mechanical properties that form the foundation for reliable linear shaft performance.

Chrome Layer Testing

Advanced hardness testing equipment verifies chrome plating reaches HRC58-62 specifications across the shaft surface, while adhesion tests confirm plating integrity that prevents premature flaking under bearing contact stress.

Straightness Measurement

Precision dial indicators mounted on granite surface plates detect shaft bow deviations as small as 0.005mm, verifying straightness tolerances that ensure smooth bearing motion and prevent binding in multi-shaft parallel systems.

Surface Roughness Verification

Contact profilometers measure surface finish to confirm Ra values meet 0.2-0.4μm specifications, guaranteeing the ultra-smooth surface required for quiet operation and extended bearing life in precision motion applications.

Dimensional Tolerance Control

Calibrated micrometers and ring gauges verify diameter tolerances meet g6/h6 standards throughout shaft length, ensuring consistent bearing clearances that deliver smooth motion without excessive play or binding conditions.

Final Packaging Inspection

Pre-shipment sampling inspection confirms proper protective packaging, accurate labeling, and complete documentation including test certificates and traceability records that support your quality assurance requirements.

Quality documentation and test reports available for every shipment.

Request Quality CertificatesLinear Shaft Selection Guide: Engineering Best Practices

Make informed specification decisions by understanding how shaft diameter, length, surface treatment, and bearing compatibility interact to determine optimal system performance and longevity for your specific application.

Selecting Diameter Based on Load Requirements

Shaft diameter determines load capacity and system rigidity, requiring careful calculation of static and dynamic loads to prevent deflection that compromises positioning accuracy and accelerates bearing wear.

- Load Calculation: Sum all gravitational loads, acceleration forces, and external process forces acting on the moving carriage, then apply safety factors of 1.5-2.0 for general automation and 2.5-3.0 for shock-loaded applications.

- Deflection Limits: Maximum shaft deflection should not exceed 0.05mm per 1000mm length under full load to maintain bearing alignment, requiring larger diameters for long unsupported spans or heavy payloads.

- Standard Size Selection: Choose next larger standard diameter when calculated requirements fall between sizes, as undersized shafts cause excessive deflection leading to premature bearing failure and positioning errors.

Determining Optimal Shaft Length

Shaft length selection balances travel stroke requirements with structural rigidity, while considering support bearing placement to maintain straightness under operational loads throughout the motion range.

- Travel Stroke Calculation: Minimum shaft length equals required stroke plus bearing lengths plus 100-150mm safety margins at each end to prevent bearing overhang that creates moment loads and premature wear.

- Support Span Limits: Maximum unsupported shaft length varies with diameter—typically 20-30 times diameter for light loads, requiring intermediate support bearings for longer spans to prevent excessive mid-span deflection.

- Thermal Expansion: Consider 0.011mm/m/°C steel expansion coefficient when specifying lengths for high-temperature applications, allowing proper clearances at fixed mounting points to prevent thermal buckling stress.

Surface Treatment Selection Criteria

Surface treatment choice depends on environmental exposure and duty cycle severity, with chrome plating essential for corrosive conditions while precision grinding alone suffices for clean, temperature-controlled environments.

- Chrome Plating Benefits: Essential for humid environments, outdoor installations, and food processing where corrosion protection outweighs cost premium, extending service life 3-5 times versus unplated shafts in challenging conditions.

- Grinding-Only Applications: Adequate for enclosed machinery in climate-controlled facilities with regular maintenance schedules, offering cost savings when environmental protection is not critical to longevity.

- Special Coatings: Consider stainless steel substrates for extreme corrosion exposure, black oxide for optical systems requiring non-reflective surfaces, or specialized coatings for high-temperature or chemical process applications.

Matching Bearings and Housing Components

Proper bearing selection ensures compatibility with shaft diameter tolerances and surface finish, while housing alignment maintains geometry required for smooth motion and prevents premature component failure.

- Clearance Classification: Match bearing internal clearance to shaft diameter tolerance—g6 shafts pair with normal clearance bearings while h6 shafts require slight clearance adjustment to prevent binding or excessive play.

- Load Rating Verification: Select bearings with dynamic load ratings exceeding calculated system loads by 50-100%, accounting for impact factors, acceleration forces, and desired L10 life expectancy targets for maintenance planning.

- Housing Alignment: Specify housing mounting surfaces machined parallel within 0.02mm to ensure shaft parallelism, as misalignment creates moment loads that drastically reduce bearing life and cause binding in multiple-shaft systems.

Unsure about specifications for your project? Our engineers provide free consultation.

Get Engineering SupportYiCheng Linear Shaft Competitive Advantages

Our unique combination of technical expertise, integrated supply capabilities, and customer-focused service creates compelling value beyond simple product transactions, establishing long-term partnerships built on reliability and performance.

Complete Linear Motion System Integration

Single-source procurement for linear shafts, guide rails, ball screws, bearings, and coupling components eliminates compatibility concerns and vendor coordination overhead. Our engineers ensure optimal component matching while consolidated purchasing reduces your procurement costs and simplifies inventory management across multiple product lines.

Experienced Engineering Technical Support

Mechanical engineers with 15+ years in linear motion applications provide guidance throughout your project lifecycle, from initial specification selection through installation troubleshooting. This expertise helps you avoid costly design errors, optimize system performance, and accelerate time-to-market for new product development initiatives.

Proven International Market Experience

Fifteen years serving customers across USA, UK, Germany, Thailand, and 50+ countries provides deep understanding of diverse market requirements, international standards compliance, and cross-cultural business practices. Our established logistics networks and documentation expertise streamline customs clearance and delivery to your facility worldwide.

Flexible Manufacturing & Quick Response

Advanced production planning systems enable 24-hour quotation turnaround and flexible minimum order quantities supporting prototype development through high-volume production. This agility accelerates your product development cycles while eliminating inventory risk, allowing you to scale production responsively as market demand evolves.

Discover how our integrated approach simplifies your linear motion procurement.

Explore Partnership BenefitsWhat Our Customers Say About YiCheng Linear Shafts

Real feedback from automation engineers and equipment manufacturers who rely on our linear shafts for mission-critical motion control applications worldwide.

The straightness tolerance on these chrome-plated shafts is exceptional. We've been running them 24/7 in our assembly line for eight months with zero bearing failures. The technical support team helped us select the right specifications for our load requirements, which saved us from the oversizing mistakes we made with our previous supplier.

Quick response time and flexible MOQ made prototyping our new gantry system much easier. We ordered small quantities of three different shaft diameters to test, and YiCheng delivered everything within two weeks. The custom cutting service saved us significant machining costs, and the packaging protected everything perfectly during international shipping.

We consolidated our linear motion component purchases with YiCheng after comparing quality and pricing from multiple suppliers. The ability to order shafts, bearings, and support units together simplified our procurement significantly. Quality consistency has been excellent across multiple orders, and the test certificates provide the documentation our quality system requires.

For our medical device application, surface smoothness and quiet operation were critical requirements. The precision-ground finish on these shafts exceeded our expectations, and our testing showed noise levels well below competitive products. The engineering team understood our unique requirements immediately and recommended specifications that met both performance and budget constraints.

Join hundreds of satisfied customers worldwide.

Start Your Success StoryReady to Start Your Linear Shaft Project?

Whether you need standard specifications or custom-engineered solutions, our team is ready to support your automation project from initial consultation through production delivery. Experience the YiCheng difference with technical expertise, quality manufacturing, and customer-focused service.