Precision Linear Rail Solutions for Industrial Motion

High precision, high rigidity, low noise operation, making your equipment run more smoothly.

Common Challenges in Linear Motion Systems

Industrial equipment operators face critical issues that impact productivity, precision, and profitability

Inconsistent Precision

Unstable rail accuracy causes repetitive positioning errors, leading to defective products and wasted materials in your production line

Short Service Life

Premature rail wear forces frequent maintenance shutdowns, increasing downtime costs and disrupting your manufacturing schedule

Insufficient Load Capacity

Inadequate rigidity and load handling create unwanted vibrations, compromising your equipment's accuracy and finished product quality

Poor Technical Support

Model mismatches and lack of supplier engineering assistance result in costly installation errors and delayed project completion

Slow Delivery Times

Insufficient inventory and extended lead times stall your production upgrades, causing missed deadlines and lost business opportunities

Hidden Costs

Unclear pricing structures and unexpected expenses make budget planning difficult, eroding your project profit margins

Ready to eliminate these costly problems from your operations?

Get Expert Solution NowWhy Choose Our Linear Rails

Engineered solutions that directly address your motion control challenges with proven results

Complete Precision Range

Full accuracy grade selection (C / H / P / SP) ensures you get the exact precision your application demands, eliminating costly over-specification or performance gaps

High-Rigidity Design

Superior structural engineering delivers exceptional stiffness and load capacity, minimizing deflection and vibration for consistently smooth, accurate motion

Extensive Model Selection

Multiple material options and slider configurations let you optimize performance for your specific environment, from dust-prone to high-speed applications

Rapid Supply Capability

Substantial stock of common sizes means immediate availability for urgent projects, keeping your production schedule on track without compromise

Expert Engineering Support

Experienced mechanical engineers provide comprehensive selection guidance, ensuring optimal rail specification for your load, speed, and accuracy requirements

100% Quality Inspection

Every rail undergoes rigorous smoothness verification and full inspection protocols, guaranteeing flawless operation from the moment of installation

Experience the difference precision manufacturing makes

Request Technical ConsultationLinear Rail Fundamentals

Understanding the technology behind precision linear motion helps you make informed decisions for your applications

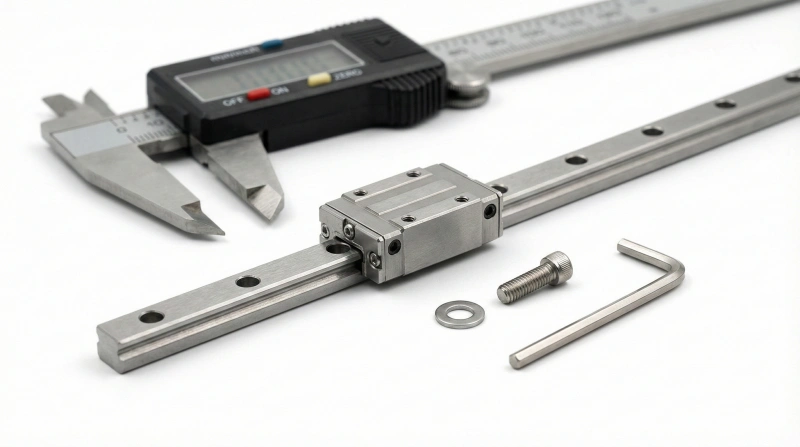

Linear Rail System Components

A linear rail system combines a precision-ground rail with ball-bearing sliders. The rail provides a straight guideway while sliders move along it with minimal friction, enabling repeatable positioning accuracy down to microns for demanding applications

Understanding Precision Grades

Accuracy grades (C, H, P, SP) define allowable straightness and parallelism tolerances. Higher grades mean tighter tolerances: C-grade suits general automation, H-grade fits precision machinery, while P and SP grades serve ultra-high-precision applications like semiconductor equipment

Linear Rail vs Circular Guide Comparison

Linear rails offer superior load capacity, rigidity, and precision compared to circular guides. Their four-direction load capability handles complex forces better, making them ideal for CNC machines and heavy-duty automation where circular guides would deflect or bind

Diverse Application Scenarios

Linear rails excel in CNC machining centers providing cutting tool precision, automation equipment enabling fast pick-and-place operations, 3D printers delivering layer accuracy, and medical devices requiring sterile, smooth motion for patient safety

Need help understanding which solution fits your needs?

Talk to Our Application EngineersLinear Rail Model Selection Guide

Critical factors to consider when specifying linear rails for optimal performance and longevity

Load Requirements

Calculate both dynamic load (moving conditions) and static load (stationary holding) to ensure adequate capacity. Include safety factors for shock loads and moment loads from off-center weights to prevent premature bearing failure

Speed & Acceleration

Higher velocities and rapid acceleration cycles demand rails with superior ball recirculation systems and appropriate preload. Match rail specifications to your motion profile to avoid excessive wear and maintain positioning accuracy over time

Precision Level Selection

Choose accuracy grade based on your tolerance requirements. General automation accepts C-grade, precision machining needs H-grade, while ultra-fine applications require P or SP grades for micron-level positioning repeatability

Preload Classification

Preload eliminates internal clearance, enhancing rigidity and positioning precision. Light preload suits high-speed applications, medium preload balances performance, and heavy preload maximizes stiffness for heavy cutting operations

Length & Mounting Method

Rail length must accommodate full travel plus slider length. Consider mounting surface flatness requirements and select appropriate installation method—top mounting, side mounting, or inverted—based on your machine structure

Environmental Factors

Assess operating conditions including dust exposure, temperature extremes, vibration levels, and moisture. Specify seals, corrosion-resistant materials, and appropriate lubrication to ensure reliable performance in challenging environments

Unsure about the right specifications for your application?

Get Free Selection AssistancePremium Linear Rail Series

Industry-leading linear motion solutions engineered for precision, durability, and performance across demanding applications

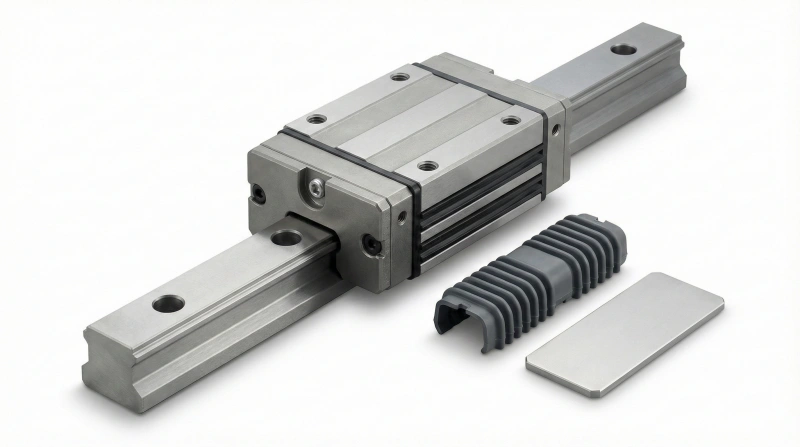

HGH / HGW Series

Heavy-duty linear guide rails delivering exceptional load capacity and rigidity for demanding industrial applications

- Load capacity up to 55,000N

- High moment rigidity

- Four-direction equal load design

EGH / EGW Series

Standard profile rails offering optimal balance between performance and cost for general automation equipment

- Versatile mounting options

- Excellent price-performance ratio

- Wide range of sizes available

MGW / MGN Miniature Rails

Compact precision guides perfect for space-limited applications requiring high accuracy in tight dimensions

- Ultra-compact design

- High precision grade available

- Ideal for small automation

QR Series Slider Blocks

Specialized slider blocks with quiet operation technology, reducing noise levels without compromising performance

- Low noise operation

- Smooth motion characteristics

- Extended service life

OSG Special Models

Application-specific rail designs engineered for unique environmental conditions and specialized requirements

- Corrosion-resistant options

- High-temperature capability

- Custom sealing solutions

Custom Extended Length Rails

Non-standard length rails manufactured to your exact specifications, supporting large-format equipment requirements

- Lengths up to 6 meters

- Precision-matched joints

- Maintained accuracy standards

Can't find the exact model you need?

Contact Our Product SpecialistsTechnical Parameters Reference

Comprehensive specifications to assist in precise model selection and system design

| Model Series | Rail Width (mm) | Block Length (mm) | Dynamic Load C (kN) | Static Load Co (kN) | Precision Grade | Weight (kg/m) | Ball Circulation |

|---|---|---|---|---|---|---|---|

| HGH15 | 15 | 34.5 | 9.05 | 13.5 | C, H, P, SP | 1.53 | Gothic Arch |

| HGH20 | 20 | 44.0 | 14.32 | 21.2 | C, H, P, SP | 2.36 | Gothic Arch |

| HGH25 | 25 | 54.0 | 22.13 | 33.2 | C, H, P, SP | 3.98 | Gothic Arch |

| HGH30 | 30 | 64.0 | 31.86 | 48.0 | C, H, P, SP | 5.40 | Gothic Arch |

| EGH15 | 15 | 40.0 | 8.12 | 12.1 | C, H, P | 1.42 | 2-Point Contact |

| EGH20 | 20 | 48.0 | 12.85 | 19.0 | C, H, P | 2.18 | 2-Point Contact |

| MGN9 | 9 | 23.3 | 2.35 | 3.43 | C, H, P | 0.48 | Gothic Arch |

| MGN12 | 12 | 29.3 | 4.68 | 6.86 | C, H, P | 0.85 | Gothic Arch |

• Load ratings are based on a service life of 50km under standard conditions

• Precision grades: C (Normal), H (High), P (Precision), SP (Super Precision)

• Actual load capacity may vary based on preload, lubrication, and operating conditions

• Contact our engineers for detailed calculations and application-specific recommendations

Need complete technical specifications or CAD files?

Download Full CatalogLinear Rail Customization Services

Tailored modifications to meet your exact application requirements and specifications

Non-Standard Lengths

Rails manufactured to your precise length requirements from 100mm to 6000mm, eliminating need for cutting or joining standard sizes, reducing installation complexity

Special Hole Patterns

Custom mounting hole positions, thread types, and spacing patterns machined to match your equipment design, ensuring perfect fitment without modification

Machined End Features

Precision chamfering, counterbores, and end-face modifications for easier installation and integration with existing machinery components

Protective Coatings

Anti-corrosion treatments, specialized surface coatings, and enhanced sealing options for harsh environments including chemical exposure and extreme temperatures

Selectable Preload Levels

Choose from light, medium, or heavy preload classifications optimized for your specific speed, load, and rigidity requirements

OEM Branding Services

Professional laser engraving or marking with your company logo, part numbers, and specifications for seamless integration into your branded product lines

Have unique requirements beyond standard offerings?

Discuss Custom SolutionsEngineering & Technical Support

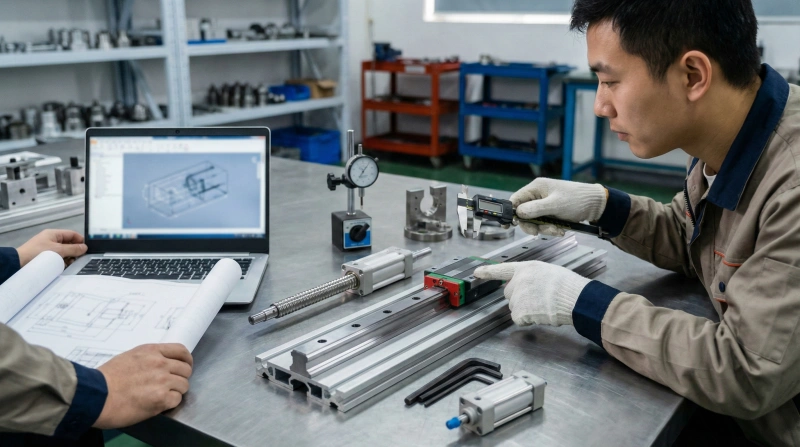

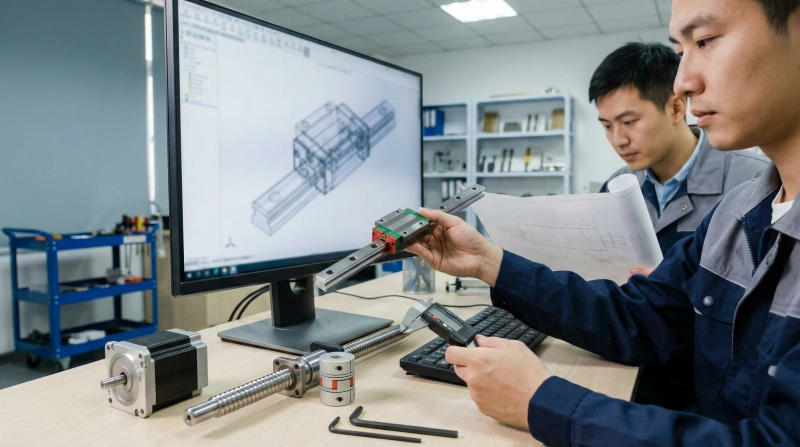

Comprehensive design assistance from experienced mechanical engineers ensuring optimal linear rail selection and implementation

Free Model Selection

Our engineers analyze your load requirements, speed profiles, duty cycles, and environmental conditions to recommend the optimal rail series, size, and accuracy grade for maximum performance

Drawing Review Service

Submit your CAD files for professional evaluation of mounting arrangements, clearances, and integration details to identify potential issues before manufacturing begins

Complete System Design

Comprehensive linear motion system design including motor sizing, drive mechanism optimization, and structural support recommendations for integrated solutions

Design Improvement Tips

Leverage our decades of experience to optimize your designs for reduced costs, improved performance, simplified assembly, or extended service life

CAD Model Library

Access comprehensive 3D CAD models and 2D drawings in all major formats including STEP, IGES, DWG, and PDF for seamless design integration

24/7 Technical Support

Round-the-clock access to our engineering team for troubleshooting, application questions, and ongoing project support throughout your product lifecycle

Ready to leverage professional engineering expertise for your project?

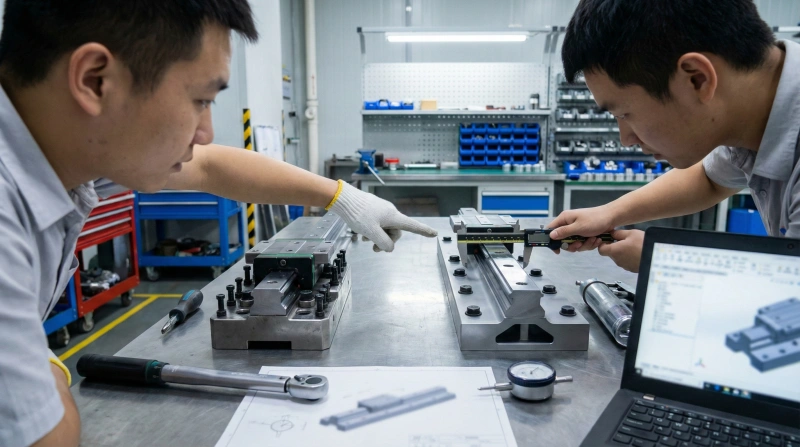

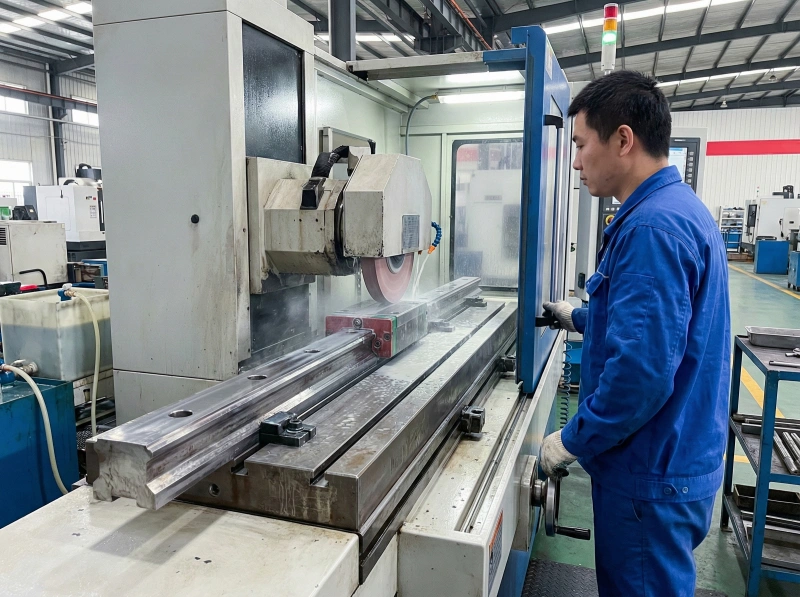

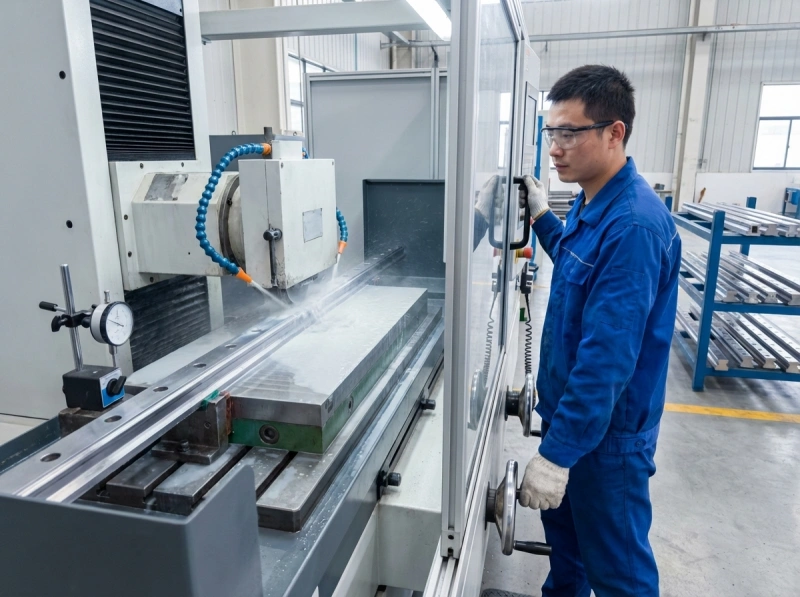

Schedule Technical ConsultationQuality Control & Inspection System

Rigorous multi-stage testing protocols ensure every linear rail meets exact specifications before shipment

Material Composition Testing

Spectroscopic analysis verifies alloy composition meets specifications, ensuring proper hardness, wear resistance, and dimensional stability throughout the rail's service life

Hardness Verification

Rockwell hardness testing at multiple points confirms proper heat treatment depth and uniformity, critical for achieving specified load ratings and preventing premature surface wear

Precision Measurement

CMM measurement validates straightness, parallelism, and dimensional accuracy against tolerance specifications. Each rail is certified to its stated precision grade through documented inspection

Smooth Motion Testing

Every slider assembly undergoes motion testing across full travel length to detect any roughness, binding, or inconsistencies. Only units exhibiting perfectly smooth operation pass final inspection

Surface Finish Inspection

Visual and optical inspection identifies surface defects, coating irregularities, or finish imperfections that could affect appearance, corrosion resistance, or functional performance

Final Pre-Shipment Audit

100% reinspection before packaging verifies model number accuracy, completeness of accessories, proper lubrication application, and protective packaging to prevent transit damage

Want to see our quality documentation and certifications?

Request Quality ReportsProduction Capacity & Supply Chain Excellence

Robust manufacturing infrastructure and strategic inventory management ensure consistent product availability

Strong Manufacturing Network

Strategic partnerships with certified factories provide production flexibility and capacity scalability, allowing us to meet sudden demand surges without compromising quality or delivery timelines

Ready-to-Ship Inventory

Comprehensive stock of popular sizes and configurations enables same-day or next-day shipment for urgent requirements, eliminating production lead time delays for standard models

Flexible Order Quantities

Whether you need single rails for prototyping or container loads for production, we accommodate all order sizes without minimum order quantity restrictions or price penalties for small batches

Expedited Delivery Options

Multiple shipping methods including air freight and express courier services ensure your rails arrive when needed, with real-time tracking visibility throughout the delivery process

Need to confirm stock availability for your project?

Check Inventory StatusManufacturing Excellence & Quality Facilities

Behind every precision linear rail is advanced manufacturing technology and experienced craftsmanship

Interested in visiting our facilities or partner workshops?

Schedule Factory TourCustomer Success Stories

Trusted by industry professionals worldwide for delivering precision, reliability, and exceptional service

"The HGH series rails transformed our CNC machining accuracy. Positioning repeatability improved by 40% and we've experienced zero failures after 18 months of continuous operation. Their engineering team provided excellent technical support during installation."

"Outstanding product quality at competitive pricing. We switched from our previous supplier and immediately noticed smoother motion characteristics. The complete technical documentation and CAD files made integration seamless. Highly recommended for European automation projects."

"Their custom length rails solved a critical design challenge. Fast delivery exceeded expectations - received our order in 10 days including custom modifications. The technical consultation helped us optimize our gantry design for better load distribution."

"We've standardized on their MGN miniature rails for all our 3D printer models. Consistent precision across batches and excellent availability. Their inventory management system ensures we never face production delays. Professional partnership from start to finish."

"Exceptional engineering support during our medical device development. They helped us select the right precision grade and preload for our application. The stainless steel option meets all our hygiene requirements. Patient feedback on equipment smoothness has been outstanding."

"Reliable supply partner for our packaging machinery production line. They consistently deliver on schedule with zero quality issues. Their batch-to-batch consistency means we don't need to adjust our assembly process. True professional-grade components at fair pricing."

Join hundreds of satisfied customers worldwide

Start Your Success StoryReady to Start Your Linear Rail Project?

Tell us your device load, speed, and size to receive a quick selection and quotation. Our engineering team is ready to help you select the perfect linear rail solution for your application.