High-Precision Lead Screws for Smooth Linear Motion

Engineered for automation equipment, 3D printers, CNC machines, and laboratory instruments requiring reliable linear positioning

Common Challenges Buyers Face

We understand the critical issues that keep engineers and procurement managers up at night when sourcing lead screws

Inconsistent Precision

Poor manufacturing tolerances create vibration and positioning errors that compromise your equipment's performance and accuracy

Short Service Life

Inadequate heat treatment from budget suppliers leads to premature wear, forcing costly replacements and production downtime

Delayed Deliveries

Unreliable lead times disrupt your assembly schedule, causing project delays and frustrated customers waiting for their orders

Compatibility Issues

Lack of technical guidance on matching lead screws with guide rails and bearings results in system inefficiency and integration headaches

Selection Confusion

Overwhelming choices between T8, TR10, TR12, and ACME series without clear guidance makes specification decisions frustrating and time-consuming

Poor After-Sales Support

Suppliers disappear after payment, leaving you stranded when technical questions arise or issues need immediate resolution

Ready to work with a supplier who understands these challenges?

Talk to Our Technical TeamWhy Engineers Choose Us

Technical expertise meets manufacturing excellence - your complete solution for precision lead screws and motion control systems

Expert Technical Team

Our mechanical design engineers provide professional selection support, ensuring you choose the optimal lead screw configuration for your specific application requirements

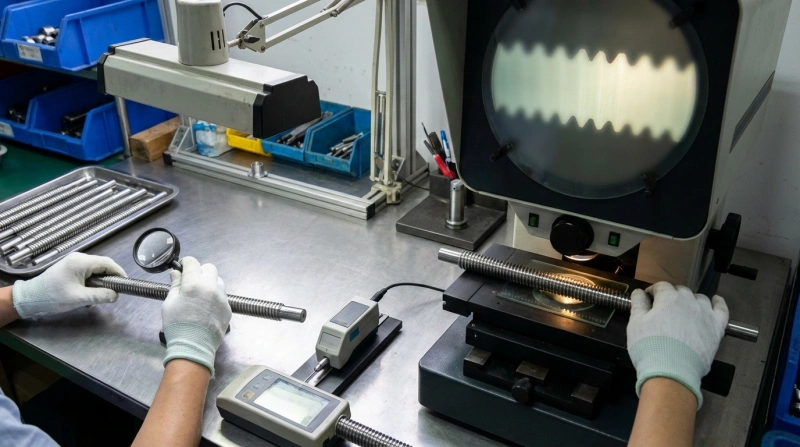

Precision Testing Equipment

Advanced concentricity and pitch accuracy measurement systems guarantee quality, with detailed factory inspection reports provided for complete traceability

Multi-Material Options

Choose from carbon steel, alloy steel, or stainless steel materials to match your operating environment, load requirements, and corrosion resistance needs

Flexible Customization

Custom pitch, thread profile, end machining, and nut specifications ensure perfect integration with your existing systems and unique design requirements

Reliable Delivery

Our agile 10-person team structure enables rapid response times and consistent delivery schedules that keep your production timeline on track

Global Validation

Trusted by equipment manufacturers in USA, UK, and Southeast Asia, with proven performance in demanding industrial applications worldwide

Experience the difference technical expertise makes

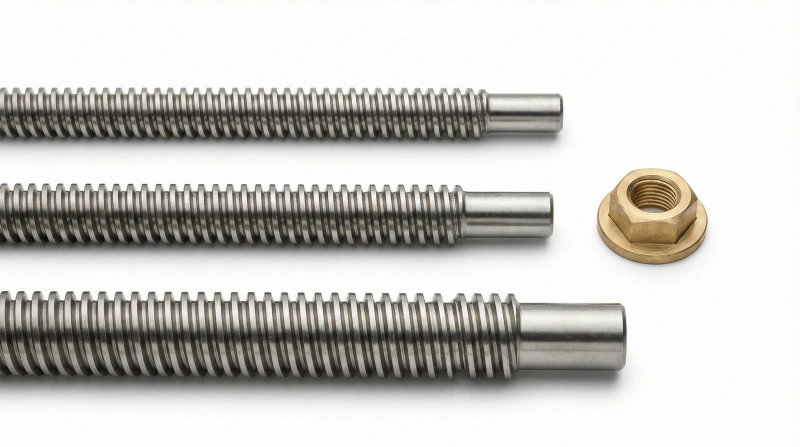

Explore Our SolutionsComplete Lead Screw Product Range

From standard T8 series to specialized custom configurations - find the perfect linear motion solution for your application

T8 Lead Screw Series

8mm diameter, 2mm pitch | Ideal for 3D printers, small CNC machines, and precision positioning applications

TR Series Lead Screws

TR10, TR12, TR14 options | Perfect for automation equipment requiring higher load capacity and longer service life

ACME Thread Series

29° thread angle | Superior strength for heavy-duty industrial machines, presses, and lifting equipment

Stainless Steel Models

304/316 grade options | Essential for medical devices, food processing, and corrosive environment applications

Complete Nut Assemblies

Brass, POM, bronze options | Pre-assembled combinations ensure perfect fit and eliminate compatibility concerns

Custom Configurations

Any size, pitch, length | Engineered to your exact specifications with special end machining and surface treatments

Can't find what you need? We specialize in custom solutions

Discuss Your RequirementsTechnical Specifications

Detailed dimensional and performance parameters for precise system integration

| Model | Dimensions | ||

|---|---|---|---|

| Ball Dia | Pitch | Lead | |

| T8 | 8mm | 1 | 1 |

| 8mm | 2 | 2 | |

| 8mm | 2 | 4 | |

| 8mm | 2 | 8 | |

| 8mm | 2 | 10 | |

| 8mm | 2 | 12 | |

| 8mm | 2 | 14 | |

| T10 | 10mm | 2 | 2 |

| 10mm | 2 | 4 | |

| 10mm | 2 | 8 | |

| 10mm | 2 | 10 | |

| 10mm | 2 | 12 | |

| 10mm | 2 | 14 | |

| 10mm | 2 | 16 | |

| T12 | 12mm | 2 | 2 |

| 12mm | 2 | 4 | |

| 12mm | 2 | 8 | |

| 12mm | 2 | 10 | |

| 12mm | 2 | 12 | |

Understanding Lead Screw Fundamentals

Make informed decisions with clear, practical knowledge about lead screw technology and selection criteria

Lead Screw vs. Ball Screw: Know the Difference

Lead screws use sliding contact for 20-50% efficiency at lower cost, making them perfect for positioning applications where speed isn't critical. Ball screws achieve 90% efficiency through rolling contact but cost significantly more. Choose lead screws when you need reliable, cost-effective linear motion without the maintenance complexity of ball bearings.

Trapezoidal vs. ACME Thread Profiles

Trapezoidal threads (30° angle) offer easier manufacturing and wider global availability as the ISO standard. ACME threads (29° angle) provide superior strength for heavy loads and easier nut replacement in high-wear applications. The choice depends on your load requirements, regional manufacturing standards, and maintenance accessibility needs.

Critical Terminology Explained

Pitch: Distance between adjacent threads (affects resolution). Lead: Linear travel per rotation (can equal or exceed pitch in multi-start threads). Thread Profile: Cross-sectional shape determining load capacity. Backlash: Free play when direction reverses (critical for precision positioning). Understanding these terms enables accurate specification and prevents costly mistakes.

Common Application Scenarios

3D printers use T8 screws for Z-axis control requiring precise layer positioning. CNC machines employ TR series for higher loads in milling operations. Medical equipment relies on stainless steel versions for sterile environments. Industrial presses utilize ACME threads for maximum load capacity. Each application demands specific combinations of material, pitch, and thread profile.

Thread Profile Comparison

Visual reference showing trapezoidal vs. ACME thread angles and their structural differences

Need help selecting the right lead screw for your application?

Get Free Technical ConsultationMaterial Science & Heat Treatment Essentials

Understanding material quality and thermal processing determines lead screw longevity and performance reliability

Judging Material Quality

Premium lead screws use verified alloy steel (45# or C45) with certified mill test reports. Visual inspection reveals uniform grain structure without inclusions. Hardness testing confirms proper carbon content.

Heat Treatment Importance

Proper induction hardening creates a hardened surface layer (HRC 50-58) while maintaining a tough core. This prevents premature wear while avoiding brittleness from over-hardening.

Nut Material Selection

POM: Low friction for clean environments. Brass: Good wear resistance. Bronze: Superior load capacity. Steel: Maximum strength for heavy-duty lifting.

Corrosion Resistance

Zinc Plating: Indoor use. Chrome: Industrial (2-5 years). 304 Stainless: Food/pharma (5-10 years). 316 Stainless: Marine/chemical environments.

Unlimited Customization Possibilities

Beyond standard products - we engineer lead screws tailored to your exact specifications

End Machining & Modifications

CNC turning for flat ends, threaded ends (M6-M20), keyways, flats for motor coupling, or custom profiles matching your existing shafts.

Special Pitch Configurations

Custom pitch from 0.5mm to 20mm for precise speed-to-resolution optimization. Multi-start threads for increased lead.

Nut Shape Customization

Flanged nuts with mounting holes, cylindrical nuts, anti-backlash spring-loaded designs, or fully custom geometries from your CAD files.

Precision Length Cutting

Any length from 50mm to 6000mm cut to ±0.5mm tolerance. We maintain thread integrity at cut ends.

Surface Treatment Options

Zinc plating for corrosion protection, chrome plating for hardness, black oxide for appearance, Teflon coating, or specialized coatings.

Complete System Integration

Matched guide rail systems, compatible linear bearings, shaft support blocks, and motor couplings for a complete solution.

Understanding Efficiency & Backlash Control

Master the trade-offs between efficiency, precision, and cost to optimize your linear motion system performance

Backlash Elimination Methods

Visual comparison of standard vs. anti-backlash nut configurations

Why Lower Efficiency Isn't Always Bad

Lead screws achieve 20-50% efficiency due to sliding friction, compared to 90%+ for ball screws. However, this "inefficiency" provides natural self-locking under vertical loads - eliminating the need for brakes in many applications. The simple sliding contact is also inherently more forgiving of contamination and requires no precision ball recirculation mechanisms that can fail.

Understanding Backlash Origins

Backlash (free play during direction reversal) occurs from the necessary clearance between screw threads and nut threads. Standard manufacturing tolerances create 0.05-0.2mm of backlash. While acceptable for many applications, precision positioning requires backlash reduction. Wear over time increases backlash, particularly in high-cycle applications with inadequate lubrication.

Anti-Backlash Solutions Explained

Spring-Loaded Split Nut: Two nut halves spring-preloaded against opposite thread flanks (reduces backlash to 0.01mm). Adjustable Double Nut: Two nuts with adjustable spacing - operator can eliminate backlash periodically. Oversized Nut: Slightly larger nut creates interference fit for zero backlash but increases friction. Choose based on precision requirements versus acceptable friction increase.

When Backlash Doesn't Matter

Unidirectional motion applications (lifting, pressing) aren't affected by backlash since direction reversal doesn't occur. Low-precision positioning (±1mm tolerance) masks typical backlash amounts. High-speed travel where positioning accuracy isn't critical. Understanding your actual precision needs prevents over-specifying expensive anti-backlash solutions unnecessarily.

Unsure which backlash solution fits your application?

Get Application AnalysisYour Complete Lead Screw Selection Guide

Eight critical factors to evaluate when specifying the perfect lead screw for your application requirements

Calculate Load Requirements

Determine the maximum static and dynamic loads your lead screw must support. Include safety factors for shock loads and acceleration forces. Axial loads, radial side loads, and moment loads all impact bearing selection. Heavier loads require larger diameters, ACME threads, or material upgrades to prevent yielding.

Define Travel Stroke Length

Measure the total linear distance your application requires plus overtravel allowance. Longer unsupported lengths require larger diameters to prevent critical speed whip and buckling. Consider intermediate support bearings for strokes exceeding 20:1 length-to-diameter ratios to maintain accuracy.

Establish Speed Requirements

Calculate maximum linear velocity needed and available motor RPM. Lead screw speed = RPM × lead. Higher speeds generate heat requiring lubrication systems. Critical speed calculations prevent resonance damage. Speed limitations typically range from 300-1000 RPM depending on diameter and support.

Specify Positioning Accuracy

Define required repeatability (±0.01mm precision machining vs ±1mm material handling). Tighter tolerances demand ground screws, anti-backlash nuts, and rigid mounting. IT5-IT6 tolerance grades for precision, IT7-IT9 for general purpose. Temperature compensation may be necessary for extreme accuracy.

Choose Thread Profile Type

Trapezoidal (ISO metric) offers 30° thread angle for global compatibility and easier manufacturing. ACME (imperial) provides 29° angle with superior load capacity and easier nut replacement. Square threads give maximum efficiency but are costly to manufacture. Match thread type to your regional standards and suppliers.

Select Appropriate Material

Carbon steel (C45/45#) for standard indoor applications offers best cost-performance. Alloy steel for high-strength requirements under shock loads. 304 stainless for food/pharma industries with moderate corrosion. 316 stainless for marine/chemical environments with aggressive corrosion. Material hardness determines wear life.

Determine Nut Material

POM (Delrin) for low friction, quiet operation, and clean environments (food/medical). Brass for traditional applications with moderate wear resistance. Bronze for high-load industrial applications requiring heat dissipation. Steel for maximum strength in pressing/lifting operations. Consider self-lubricating vs externally lubricated systems.

Assess Environmental Factors

Humidity and moisture levels dictate corrosion protection needs (plating vs stainless). Operating temperature range affects lubrication selection and material expansion. Contamination presence (dust, chips, chemicals) requires bellows protection or stainless steel. Outdoor installations need weather-resistant materials and sealed bearings.

Overwhelmed by these considerations? Our engineers simplify the process

Get Expert Selection AssistanceSix-Stage Quality Assurance Process

Every lead screw undergoes rigorous inspection at multiple checkpoints ensuring consistent precision and reliability

Material Verification

Incoming raw material certificates validated against specifications. Hardness testing confirms proper alloy composition. Only certified mill test reports accepted.

Pitch Precision Testing

CMM coordinate measuring machines verify thread pitch accuracy. Automated measurement ensures consistency within ±0.02mm tolerance.

Concentricity Inspection

Runout gauges measure radial variation. Thread-to-shaft alignment verified to prevent vibration. Straightness testing ensures smooth linear motion.

Surface Quality Check

Visual inspection identifies scratches or defects. Thread profile verification using optical comparators. Surface roughness measured to spec.

Assembly Function Test

Screw-nut assemblies tested under load. Smooth operation verified through full travel range. Backlash measured and documented.

Final Inspection Report

Complete dimensional report generated with all critical measurements. Traceability codes enable batch tracking. Digital records maintained.

Built on Technical Expertise & Manufacturing Excellence

More than a supplier - your strategic partner in precision linear motion solutions with proven global capabilities

Deep Technical Design Experience

Our mechanical engineers bring over 10 years of hands-on experience in motion control system design. We don't just sell components - we solve motion challenges. From concept through implementation, our team provides application engineering support that prevents costly specification mistakes.

Robust Manufacturing Network

Strategic partnerships with certified factories provide manufacturing flexibility without quality compromise. Our vendor qualification process ensures consistent standards across all suppliers. Multi-source capability eliminates single points of failure in your supply chain.

Complete System Solutions

Beyond standalone lead screws, we provide fully integrated linear motion systems. Matched guide rails, support bearings, and mounting hardware eliminate compatibility concerns. Single-source procurement simplifies your supply chain and reduces administrative overhead.

International Trade Expertise

Seamless global logistics with comprehensive export documentation. Established shipping partnerships ensure reliable delivery to USA, UK, Europe, and Southeast Asia. Technical support continues post-delivery with multilingual communication capabilities.

Ready to experience the difference technical expertise makes?

Become a PartnerTrusted by Engineers Worldwide

Real feedback from customers who rely on our lead screws in demanding applications across diverse industries

"After struggling with inconsistent quality from our previous supplier, YiCheng's technical team helped us specify the right ACME lead screws for our CNC plasma tables. The concentricity reports they provide give us confidence, and we haven't had a single positioning issue in 8 months of production."

"We needed custom-length TR12 lead screws with specialized end machining for our automated material handling systems. YiCheng delivered exactly to spec with faster turnaround than local suppliers. The anti-backlash nuts they recommended eliminated the positioning drift we were experiencing."

"As a distributor, consistent quality and reliable delivery are critical for our business. YiCheng has become our preferred supplier for T8 and TR series lead screws. Their flexible MOQs allow us to stock diverse sizes without excessive inventory investment. Customer feedback on their products has been overwhelmingly positive."

"Our diagnostic imaging equipment requires 316 stainless steel lead screws meeting strict cleanliness standards. YiCheng understood our requirements immediately and provided material certificates. The quality matches European suppliers at significantly better pricing, and their technical knowledge impressed our entire engineering team."

Join hundreds of satisfied customers across 20+ countries

View More Case StudiesGet High-Precision Lead Screws with Fast Delivery & Technical Support

Submit your requirements and receive a detailed quote within 24 hours. Our engineers are ready to help you find the perfect solution.