High-Performance Pneumatic Cylinder Supplier

Customized Pneumatic Cylinder Solutions for Machinery Manufacturers

Industry Challenges We Solve

Machinery manufacturers face critical operational obstacles that impact production efficiency and equipment reliability. These recurring challenges demand immediate solutions from a trustworthy pneumatic component partner.

Premature Cylinder Failure

Air leakage within months forces unplanned maintenance shutdowns, reducing your equipment uptime and customer satisfaction while increasing warranty claims that damage profit margins.

Unreliable Supply Chain

Inconsistent delivery schedules from suppliers create production delays, forcing you to maintain expensive safety stock while risking project timeline failures that frustrate end customers.

Slow Custom Response

Standard cylinders don't fit your unique space constraints or load requirements, but suppliers take weeks to respond to custom specifications, delaying your engineering schedule and market launch.

Accessory Compatibility Issues

Mounting brackets and clevis attachments from different suppliers don't match cylinder specifications, creating assembly headaches and requiring custom fabrication that adds cost and time to production.

Limited Technical Support

Sales representatives lack pneumatic engineering knowledge to recommend proper bore sizes and stroke lengths for your application load calculations, leaving you to troubleshoot performance problems alone after purchase.

Unclear Pricing Structure

Hidden costs for modifications, minimum order quantities, and vague lead time commitments make budget planning difficult, while language barriers complicate negotiations with overseas suppliers during urgent procurement.

Stop losing money to these recurring problems. Partner with a cylinder manufacturer who eliminates these obstacles.

Discuss Your RequirementsSolutions That Deliver Measurable Results

Our pneumatic cylinders transform operational challenges into competitive advantages through engineering precision, quality materials, and manufacturing systems designed specifically for machinery OEMs and automation integrators.

Premium Sealing Technology

Japanese-standard polyurethane seals withstand 3 million cycles without degradation, extending maintenance intervals from months to years while eliminating unexpected downtime that disrupts your production schedules.

Precision Honed Tubes

CNC honing achieves Ra 0.4μm surface finish inside aluminum alloy tubes, ensuring smooth piston travel that prevents jerky motion and maintains positioning accuracy even after extended operation under variable loads.

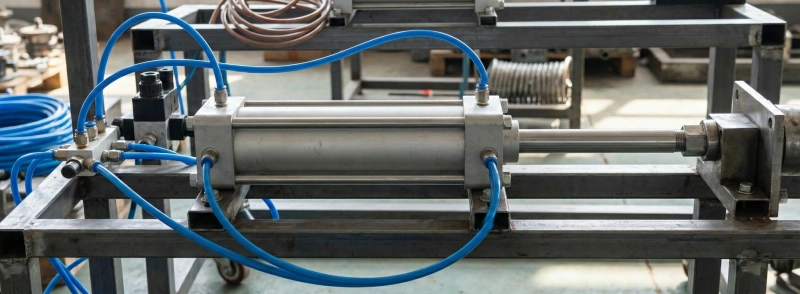

100% Leak Testing Protocol

Every cylinder undergoes automated pressure decay testing at 150% working pressure for 60 seconds, catching microscopic defects before shipping—guaranteeing zero field failures that would damage your equipment reputation with customers.

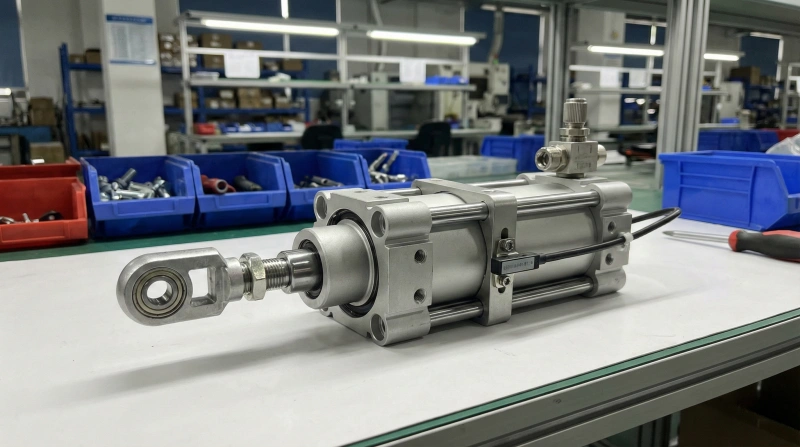

Complete Accessory System

Matching clevis mounts, trunnion brackets, and sensor switches ship together in one package, eliminating compatibility guesswork and assembly delays while ensuring proper mounting alignment for optimal force transmission.

Engineering Consultation Service

Pneumatic engineers calculate required thrust forces and recommend appropriate bore sizes based on your payload weight and cycle speed requirements—preventing oversizing that wastes air consumption and undersizing that causes sluggish performance.

Predictable Delivery Schedule

Standard models ship within 7 days, custom configurations within 21 days with tracking updates every 48 hours, allowing accurate production planning without buffer stock investments that tie up working capital unnecessarily.

These aren't just features—they're solutions to the exact problems costing you money every month.

Calculate Your SavingsBest-Selling Pneumatic Cylinder Models

These proven configurations serve thousands of automation applications worldwide, offering immediate availability with documented performance data that accelerates your design validation and reduces engineering risk.

SC Standard Cylinder

- Bore Range: 32-125mm

- Stroke: 25-1000mm

- Application: General automation, packaging machinery

- Features: Double-acting, magnetic piston

SDA Compact Cylinder

- Bore Range: 12-100mm

- Stroke: 5-100mm

- Application: Electronics assembly, medical devices

- Features: Space-saving design, high rigidity

TN Double Rod Cylinder

- Bore Range: 16-63mm

- Stroke: 50-500mm

- Application: Textile machinery, transfer systems

- Features: Dual rod ends, superior guiding

MAL Mini Cylinder

- Bore Range: 16-40mm

- Stroke: 25-300mm

- Application: Robotics, small part handling

- Features: Aluminum body, lightweight design

MA Lightweight Cylinder

- Bore Range: 16-100mm

- Stroke: 25-1000mm

- Application: Material handling, conveyor systems

- Features: Cost-effective, quick response

Magnetic Sensor Cylinder

- Bore Range: 32-100mm

- Stroke: 50-500mm

- Application: Automated positioning, detection systems

- Features: Built-in sensor groove, precise control

Can't find your exact specification? We customize any cylinder parameter to match your requirements.

Request Custom ConfigurationProven Industry Applications

Our pneumatic cylinders power critical operations across diverse industries, delivering reliable performance in demanding environments from high-speed production lines to precision positioning systems requiring consistent accuracy over millions of cycles.

Industrial Automation

Assembly line actuators, automated material handling, and robotic pick-and-place systems rely on our cylinders for precise positioning and rapid cycling, maintaining production throughput targets while minimizing downtime from component failures that disrupt manufacturing schedules.

Packaging Machinery

High-speed cartoning, bottle filling, and sealing equipment demand cylinders withstanding constant motion at elevated temperatures, our designs prevent seal degradation and maintain consistent cycle times essential for meeting production quotas without quality compromises.

Textile Equipment

Loom actuators, fabric tensioning systems, and cutting mechanisms require smooth motion control without jerking that damages delicate materials, our precision bore finishing and seal selection deliver gentle acceleration preventing thread breakage or fabric marking defects.

Food Processing Machinery

Sanitary design cylinders with stainless steel construction and FDA-approved seals meet strict hygiene standards for direct food contact applications, withstanding washdown procedures and preventing contamination risks while maintaining performance reliability critical for continuous production.

Robotics & Automation

Collaborative robots and automated guided vehicles integrate our compact cylinders for gripper actuation and lifting functions, lightweight construction reduces moving mass enabling faster cycle times while magnetic sensing simplifies position feedback integration with PLC control systems.

Automotive Industry

Welding fixture clamping, parts transfer mechanisms, and quality inspection stations demand cylinders delivering consistent force output across temperature extremes, our designs maintain positioning accuracy essential for tight tolerance assembly preventing rework costs and warranty claims.

Don't see your industry listed? Our engineers specialize in custom solutions for unique applications.

Discuss Your ApplicationUnderstanding Cylinder Types

Selecting the right cylinder type for your application ensures optimal performance, longevity, and cost-effectiveness. This guide helps engineers match cylinder configurations to specific automation requirements and space constraints.

SC Standard Cylinder

Versatile double-acting design for general industrial applications requiring reliable linear motion with magnetic piston sensing capability for position detection and automated control integration.

SDA Compact Cylinder

Space-saving thin profile ideal for tight installation spaces in electronics assembly and semiconductor equipment, delivering high force output within minimal mounting footprint for dense machinery layouts.

TN Double Rod Cylinder

Dual-sided rod extension provides superior load guiding and prevents rotation, perfect for applications requiring parallel motion transfer or mounting work pieces on both stroke ends simultaneously.

MAL Mini Cylinder

Lightweight compact construction designed for robotic arms and pick-and-place systems where minimizing moving mass is critical for achieving fast cycle times and reducing motor load requirements.

MA Light-Duty Cylinder

Economic solution for conveyor systems and material handling where budget constraints are important, offering reliable performance for moderate duty cycles at competitive pricing without compromising basic quality standards.

Magnetic Piston Cylinder

Features integrated magnetic piston ring enabling external reed switch sensors to detect position without drilling ports into barrel, simplifying automation control circuits for precise stroke end verification.

Still unsure which cylinder type fits your application? Our engineers provide free technical consultations.

Speak With an EngineerPneumatic Cylinder Operation Fundamentals

Understanding cylinder operating principles helps optimize air consumption, prevent installation errors, and troubleshoot performance issues that can arise from improper pressure regulation, inadequate flow capacity, or mechanical binding during operation.

Compressed Air Input

Pneumatic system supplies filtered, regulated air through directional control valve ports. Proper air preparation removes moisture and particles preventing seal damage while pressure regulation ensures consistent thrust output.

- Filter removes particles down to 5 microns

- Pressure regulator maintains stable supply (typically 0.5-0.7 MPa)

- Lubricator optional depending on seal material compatibility

- Flow capacity must match cylinder volume requirements for desired speed

Single-Acting Operation

Air pressure extends piston rod in one direction while internal spring or external force returns it. This design reduces air consumption by 50% but limits available retract force to spring strength plus load assistance.

- Compressed air enters one chamber pushing piston outward

- Spring compression stores return energy during extension

- Valve exhaust vents extend chamber allowing spring return

- Ideal for gravity-assisted applications or where retract force is minimal

Double-Acting Operation

Compressed air alternately enters opposite cylinder chambers creating bidirectional powered motion. This configuration provides controlled force in both directions essential for pushing/pulling operations against resistance.

- 5-way valve directs air to extend chamber while exhausting retract side

- Piston moves forward with force determined by pressure × piston area

- Valve reversal sends air to rod-side chamber for powered retraction

- Rod-side force lower due to piston rod area reducing effective surface

Cushioning Mechanism

Adjustable cushions decelerate piston before stroke ends preventing destructive impact forces. This feature extends equipment life dramatically in high-speed or heavy-load applications by absorbing kinetic energy pneumatically.

- Cushion spear enters chamber seal restricting exhaust flow

- Trapped air compresses creating back-pressure deceleration

- Adjustable needle valve controls cushion strength

- Eliminates mechanical shock transmitted to mounting structure and payload

Need help calculating required air flow, determining optimal pressure, or selecting cushion settings?

Consult Application EngineerFlexible Customization Capabilities

Our manufacturing flexibility accommodates unique design requirements that standard cylinders can't address, eliminating compromise between ideal performance and available components while maintaining competitive lead times.

Bore Size Customization

Specify any bore diameter between standard sizes to achieve precise thrust output matching your load calculations, eliminating oversized cylinders that waste compressed air and undersized units causing sluggish response or stalling under peak loads.

Stroke Length Adaptation

Order exact stroke lengths from 5mm to 2000mm without rounding to catalog sizes, optimizing equipment footprint and preventing over-travel that adds unnecessary cycle time or requires external mechanical stops for position accuracy.

Special Mounting Brackets

Design custom mounting interfaces including trunnion brackets with non-standard hole patterns, foot mounts with precision-machined datum surfaces, or flange adapters matching your existing machinery structure to eliminate welding or fabrication after delivery.

Temperature-Resistant Seals

Upgrade to Viton or silicone seals for operation in -40°C to +150°C environments, preventing premature failure in oven curing processes, cold storage applications, or outdoor installations exposed to seasonal temperature extremes that degrade standard NBR rubber.

Magnetic Ring Integration

Add embedded magnetic rings at custom positions along stroke length for multi-point position sensing using external reed switches, enabling complex motion sequences without installing multiple cylinders or expensive servo systems for intermediate stop positions.

Accessory Package Solutions

Receive cylinders with pre-mounted clevis joints, rotating rod eyes, or threaded rod ends machined per your drawings, plus matching sensor brackets and speed controllers configured as complete assemblies ready for installation without sourcing accessories from multiple suppliers.

Upload your technical drawings and specifications for a detailed customization feasibility assessment.

Submit Custom RequirementsStreamlined OEM/ODM Workflow

Our structured development process eliminates uncertainty from custom pneumatic component projects, providing clear milestones and approval checkpoints that prevent costly rework while maintaining tight delivery schedules for your production launch.

Requirement Analysis

Technical team reviews your application details including load forces, cycle rates, environmental conditions, and space constraints to recommend optimal cylinder type, bore size, and configuration preventing over-specification or performance shortfalls.

Engineering Review & Validation

CAD engineers analyze your 2D/3D drawings for manufacturing feasibility, identifying potential interference issues, mounting stress concentrations, or seal compatibility concerns before tooling investment, with proposed optimizations to reduce cost or improve reliability.

Quotation & Timeline Proposal

Receive detailed pricing breakdown separating tooling costs from per-unit pricing, with clear MOQ requirements and delivery schedules for prototype samples versus production quantities, enabling accurate budget planning and project timeline commitments to your end customers.

Prototype Sample Production

First article samples undergo full dimensional inspection and functional testing under simulated load conditions, with test reports and actual measurements provided for your engineering validation before authorizing mass production tooling and component procurement.

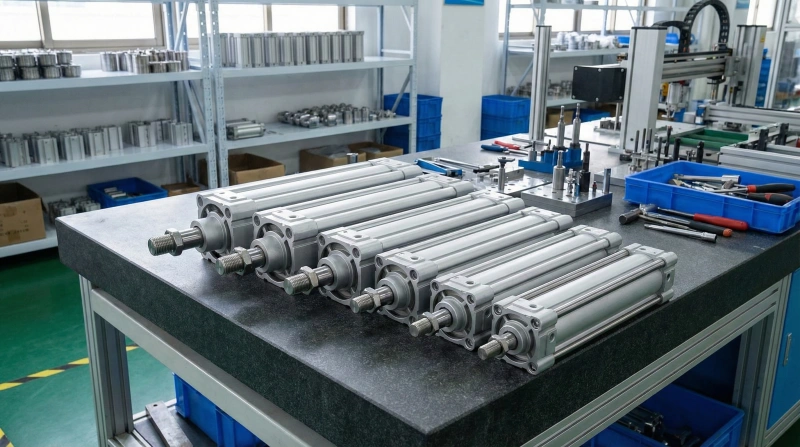

Batch Manufacturing

Production runs follow approved samples exactly using dedicated fixtures and inspection protocols that maintain consistency across batches, with statistical process control catching drift before defects occur and eliminating surprise quality issues during your assembly operations.

Quality Control & Testing

Every cylinder completes pressure testing, stroke verification, and seal integrity checks per documented procedures, with random sample destructive testing validating material properties and weld strengths meet specifications for your safety-critical or high-duty-cycle applications.

Packaging & Logistics

Cylinders receive protective packaging preventing rod damage and contamination during shipping, with proper labeling including your part numbers and batch codes facilitating traceability, while coordinating delivery timing with your production schedules to minimize warehouse storage requirements.

After-Sales Support

Technical support continues through product lifecycle with troubleshooting assistance, replacement part availability for years, and design modification support when your equipment evolves, protecting your service parts business and customer equipment uptime without supplier obsolescence concerns.

Ready to start your custom cylinder project with predictable timelines and clear communication?

Initiate Your OEM ProjectManufacturing Process Excellence

Controlled production workflows combining precision machining, rigorous testing, and systematic quality verification ensure every cylinder meets performance specifications and durability standards critical for machinery OEM reputation and customer satisfaction.

Material Preparation

Aluminum extrusions and steel rod stock undergo receiving inspection verifying material certifications before precision cutting to length with controlled tolerances, ensuring dimensional consistency across production batches and eliminating wasted material from incorrect sizing.

CNC Precision Machining

Computer-controlled machining centers bore cylinder tubes, turn piston components, and thread end caps with micron-level accuracy, using dedicated fixtures preventing tolerance stack-up that would cause binding or air leakage compromising performance reliability.

Surface Treatment

Piston rods receive hard chrome plating achieving Rc 60 hardness for scratch resistance, while cylinder tubes undergo anodizing creating corrosion-resistant oxide layer, extending service life in humid or chemically contaminated industrial environments.

Precision Assembly

Trained technicians install seals with proper stretch preventing premature wear, torque end caps to specification avoiding leaks, and verify smooth piston travel throughout stroke ensuring friction-free motion critical for positioning accuracy and energy efficiency.

Leak Testing Validation

Automated test stations pressurize each cylinder to 1.5x working pressure monitoring for pressure decay, catching microscopic seal defects or porosity before shipping, guaranteeing zero field failures that damage equipment reputation and generate costly warranty claims.

Protective Packaging

Individual cartons with foam inserts protect piston rods from impact damage during shipping, while sealed packaging prevents moisture ingress and contamination, with clear labeling including part numbers and batch codes facilitating inventory management and traceability.

Experience manufacturing quality that protects your brand reputation and reduces warranty expenses.

Schedule Factory Video TourComprehensive Quality Assurance

Multi-stage inspection protocols verify every critical parameter affecting cylinder performance and longevity, catching defects before they reach your assembly line and protecting your equipment reputation with validated quality documentation.

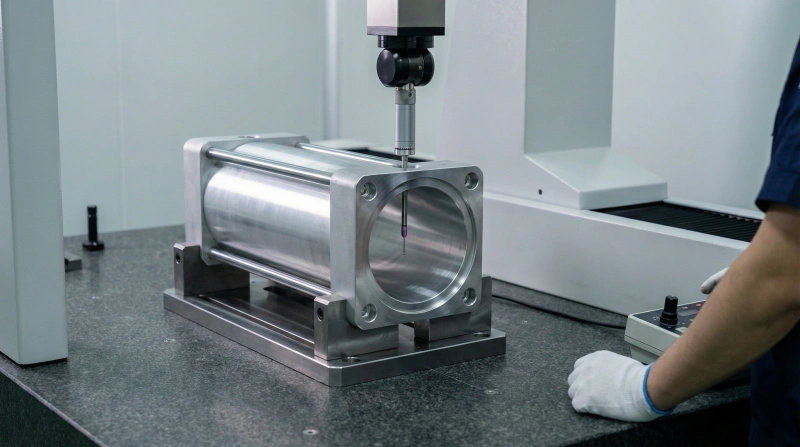

Bore Precision Measurement

Coordinate measuring machines verify internal bore diameter, roundness, and surface finish meet specifications within 0.01mm tolerance, preventing piston seal wear and air leakage caused by dimensional variations that compromise thrust consistency.

Air Tightness Verification

Every cylinder undergoes automated pressure decay testing at 150% rated pressure for 60 seconds, detecting microscopic leaks through seals or port threads invisible to visual inspection, ensuring zero failures from assembly defects after installation.

Surface Hardness Testing

Rockwell hardness testing validates piston rod chrome plating achieves Rc 60 minimum, confirming scratch resistance needed for long-term operation in abrasive environments where surface damage accelerates seal failure and causes premature replacement costs.

Cycle Endurance Validation

Random samples complete 100,000 cycle endurance tests under loaded conditions, measuring force consistency and stroke accuracy degradation over time, validating seal materials and lubrication strategies deliver promised service life in real-world duty cycles.

Seal Integrity Inspection

Visual and dimensional checks verify proper seal installation without twisting or damage, confirming correct compression preventing both immediate leaks and premature wear from improper seating that causes gradual performance degradation requiring early maintenance interventions.

Final Functional Test

Complete stroke operation tests at working pressure verify smooth motion throughout travel without binding, cushion effectiveness at stroke ends, and port functionality, catching assembly errors before shipping rather than after your production line integration attempts.

Quality documentation and test reports available for regulatory compliance and traceability requirements.

Request Quality CertificatesCustomer Success Stories

Real feedback from machinery manufacturers and automation integrators who've experienced measurable improvements in equipment reliability, reduced maintenance costs, and enhanced customer satisfaction after switching to our pneumatic cylinder solutions.

Switching to YiCheng cylinders cut our warranty claims by 60% in the first year. Their engineers helped us right-size components, eliminating oversized units wasting compressed air. Delivery consistency finally lets us maintain lean inventory without production stoppages.

Custom mounting brackets arrived pre-assembled exactly to our CAD specs, saving two weeks of fabrication time per machine build. The technical support team actually understands pneumatic system design—rare to find suppliers with genuine engineering expertise instead of just order-takers.

After struggling with two other Chinese suppliers who couldn't maintain quality consistency, YiCheng's batch-to-batch reliability finally solved our assembly line headaches. Clear English communication and proactive shipping updates made procurement stress-free for our Thailand operation.

Join hundreds of satisfied equipment manufacturers who trust our cylinders in their machines.

Start Your PartnershipGet Your Custom Quotation

Our engineering team responds within 12 hours with detailed specifications, pricing, and delivery timelines tailored to your exact requirements. Upload technical drawings for fastest turnaround on custom configurations.

Ready to Get Your Pneumatic Cylinder Quote?

Engineer team replying within 12 hours with detailed specifications, competitive pricing, and delivery schedules. Start building more reliable equipment with cylinders designed for your exact requirements.