Response Time

Within 4 hours during business days

24-hour technical support available

Don't let poor-quality circular guides compromise your production efficiency and increase downtime costs

Low-grade circular guides cause vibration and position drift during operation, leading to defective products and wasted materials.

Inferior materials and poor heat treatment result in quick deterioration, forcing frequent replacements and increasing maintenance costs.

Tight tolerances in cheap guides make assembly time-consuming and frustrating, requiring expensive rework and delaying projects.

Unbalanced components and poor finishing create excessive noise pollution and resonance, affecting workplace environment and product quality.

Batch variations from unreliable suppliers cause unpredictable performance, making quality control impossible and customer satisfaction suffer.

Delays from suppliers disrupt your production schedule, forcing rush orders at premium prices and causing missed deadlines with your customers.

Eliminate these problems with our precision-engineered circular guides

Get Expert Solutions NowEngineered solutions that deliver measurable improvements to your operations

Advanced CNC grinding equipment ensures consistent precision across all units, eliminating positioning errors and improving your product quality

Comprehensive range of sizes and configurations match diverse mechanical structures, enabling seamless integration into your existing systems

Premium bearing steel with anti-corrosion treatment extends component lifespan by 300%, reducing your long-term maintenance expenses

Substantial inventory of standard models enables rapid shipment, keeping your production schedules on track without delays

Eliminate middleman markups with direct manufacturer pricing, saving you 20-35% compared to distributors while maintaining premium quality

50,000-cycle endurance testing validates performance under real-world conditions, ensuring reliable operation throughout the rated service life

Ready to experience superior performance and reliability?

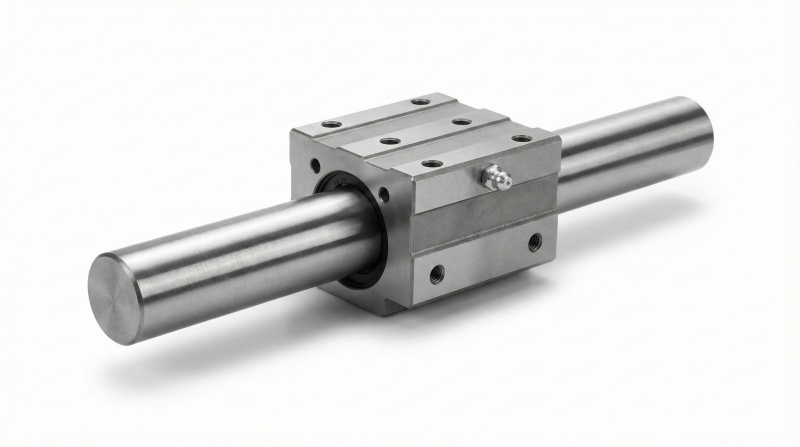

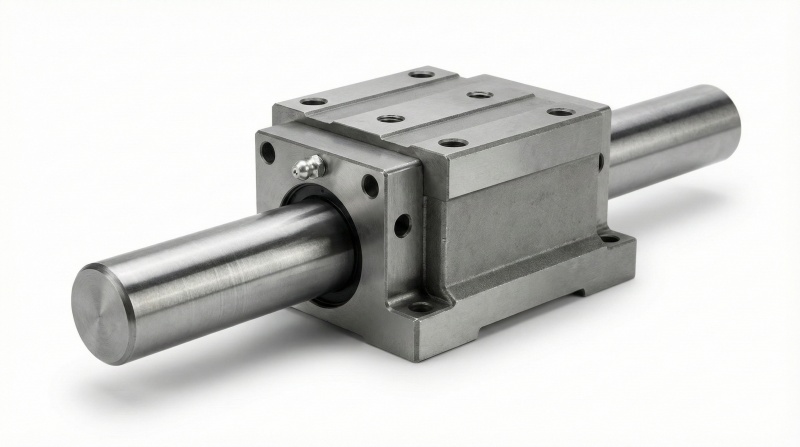

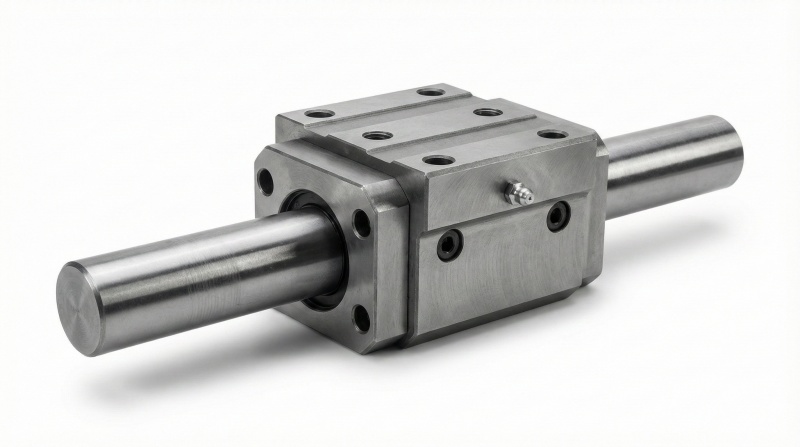

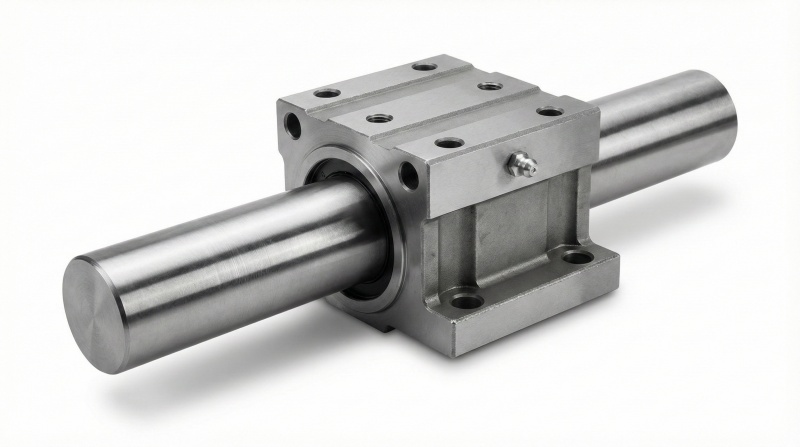

Request Your Custom QuotePremium quality circular guides engineered for demanding industrial applications

Need custom specifications or bulk pricing?

Contact Our Sales TeamLearn the key components that make circular guides essential for precision linear motion

Precision-machined steel casing provides structural support and maintains alignment under load, ensuring stable operation in demanding applications

Hardened raceway surface enables smooth rolling contact with minimal friction, delivering consistent motion quality over millions of cycles

Precision steel balls distribute load evenly across the contact surface, maximizing load capacity while maintaining low friction coefficient

Engineered geometry handles multi-directional forces effectively, providing stable performance even under complex loading conditions

Need technical guidance for your specific application?

Consult Our EngineersThe engineering principles behind precise linear motion control

Precision engineering for rotary-to-linear motion conversion

Ball bearings eliminate sliding friction by maintaining pure rolling contact, reducing coefficient of friction to 0.002-0.004 for exceptional efficiency

Multiple ball bearing contact points evenly distribute forces across the raceway surface, enabling high load capacity without compromising smoothness

Optimized bearing geometry achieves 95%+ mechanical efficiency in converting rotational input to linear output, minimizing energy loss

Sealed lubrication system maintains consistent film thickness between rolling elements, extending maintenance intervals and component lifespan

Tailored circular guide solutions designed to meet your exact specifications and application requirements

Advanced production processes and rigorous quality control ensure every circular guide meets international standards

High-precision CNC lathes machine raw materials to exact dimensions with ±0.005mm tolerance

Controlled hardening process achieves HRC 58-62 surface hardness for superior wear resistance

Multi-axis grinding centers achieve mirror-finish raceways with Ra 0.2μm surface roughness

Clean-room assembly with precision ball selection ensures optimal clearance and smooth operation

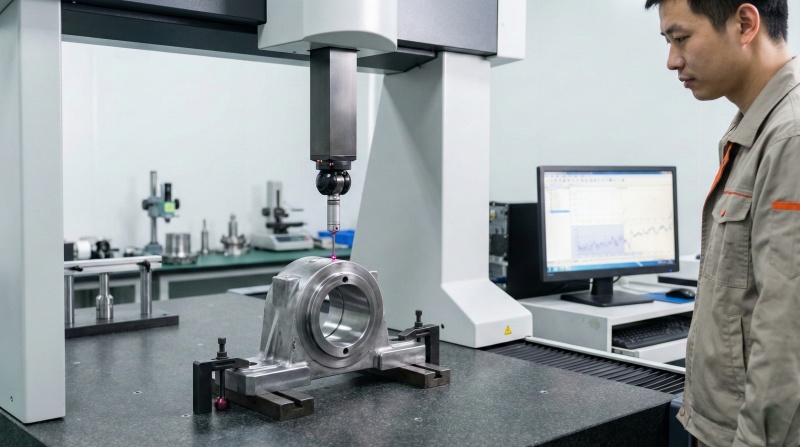

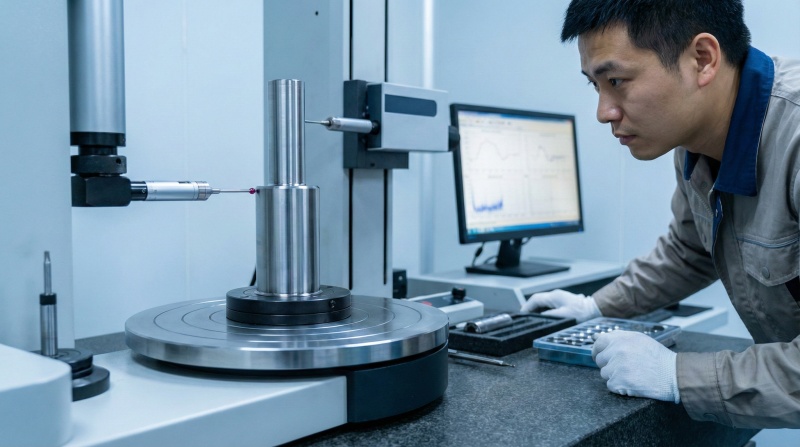

CMM measurement, load testing, and running accuracy verification certify each product before shipment

Understanding the key differences helps you select the optimal guide system for your specific application

| Performance Factor | Circular Guide (Round Rail) | Linear Guide (Profile Rail) |

|---|---|---|

| Precision Level | Standard precision (±0.05mm) | High precision (±0.01mm) |

| Load Capacity | Moderate (suitable for light-medium loads) | High (handles heavy loads efficiently) |

| Motion Type | Linear motion with rotational tolerance | Strictly linear motion only |

| Installation Complexity | Simple - forgiving to misalignment | Precise mounting surface required |

| Cost Effectiveness | Lower initial investment | Higher cost but longer service life |

| Maintenance Requirements | Minimal - self-aligning design | Regular inspection needed |

| Ideal Applications | 3D printers, simple automation, DIY CNC | Industrial CNC, precision robotics |

State-of-the-art measurement systems validate every specification and ensure consistent quality

Modern production facility equipped with advanced machinery and experienced technical team

Trusted by manufacturers worldwide for reliable circular guide solutions

"Excellent precision and smooth operation. We've installed these circular guides in 12 CNC machines and they perform consistently well. The technical support team helped us select the perfect specifications. Highly recommended for automation projects."

"Outstanding quality-to-price ratio. The circular guides arrived well-packaged and installation was straightforward thanks to the forgiving tolerances. They've been running 24/7 for 8 months without any issues. Will definitely order again."

"Professional service from quote to delivery. The customization options allowed us to get exactly what we needed for our robotic assembly line. Fast shipping and excellent after-sales support. A reliable partner for motion control components."

Tell us about your project and receive a detailed quotation within 24 hours

Within 4 hours during business days

24-hour technical support available

English, Chinese

Professional technical documentation

Worldwide delivery available

DHL, FedEx, Sea freight options