Concept

Concept

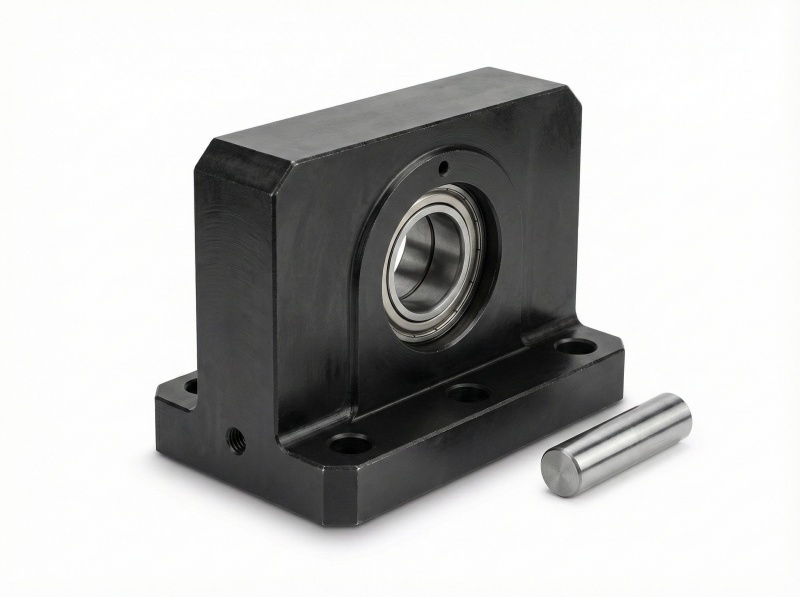

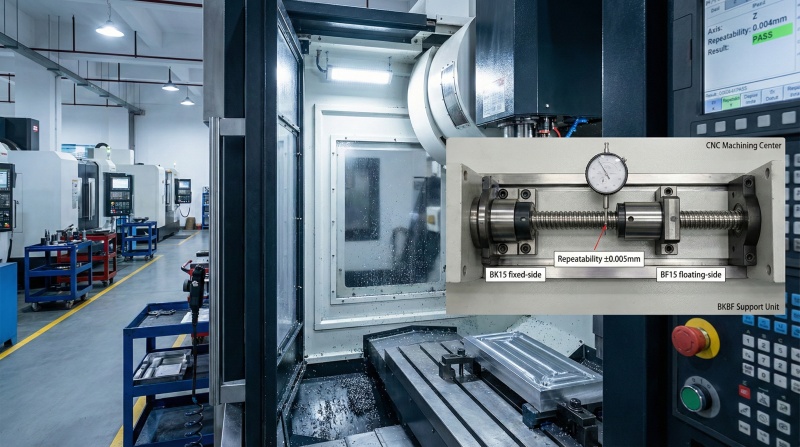

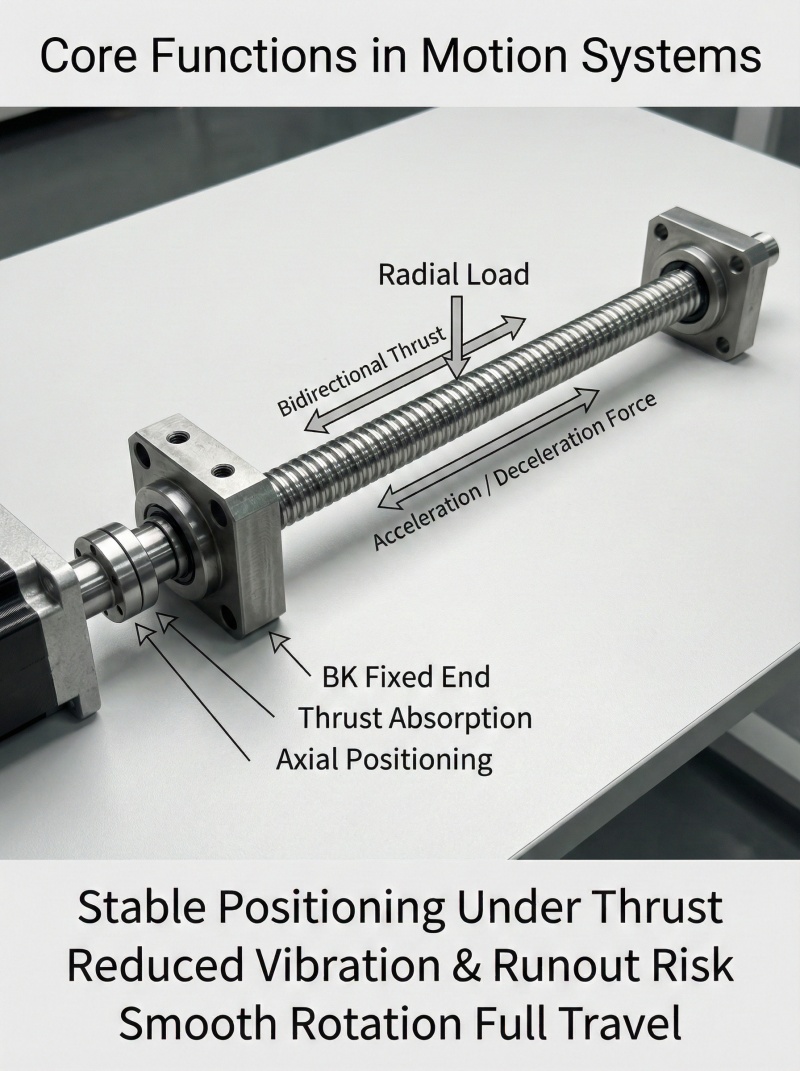

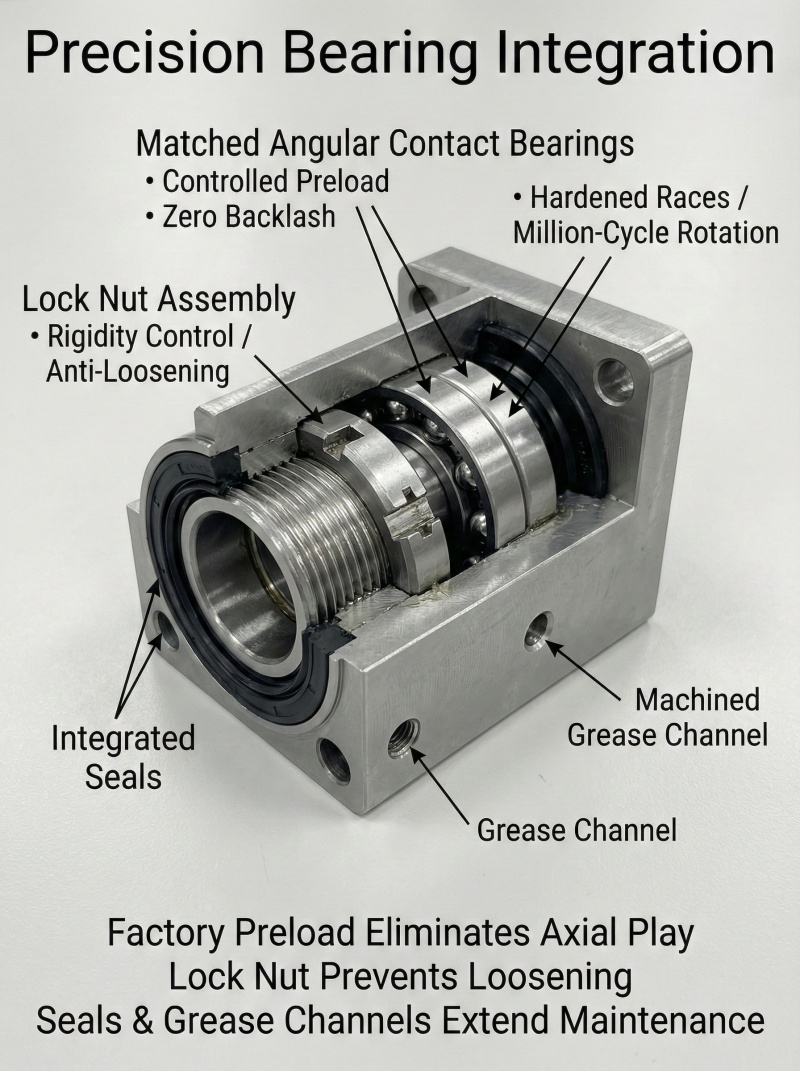

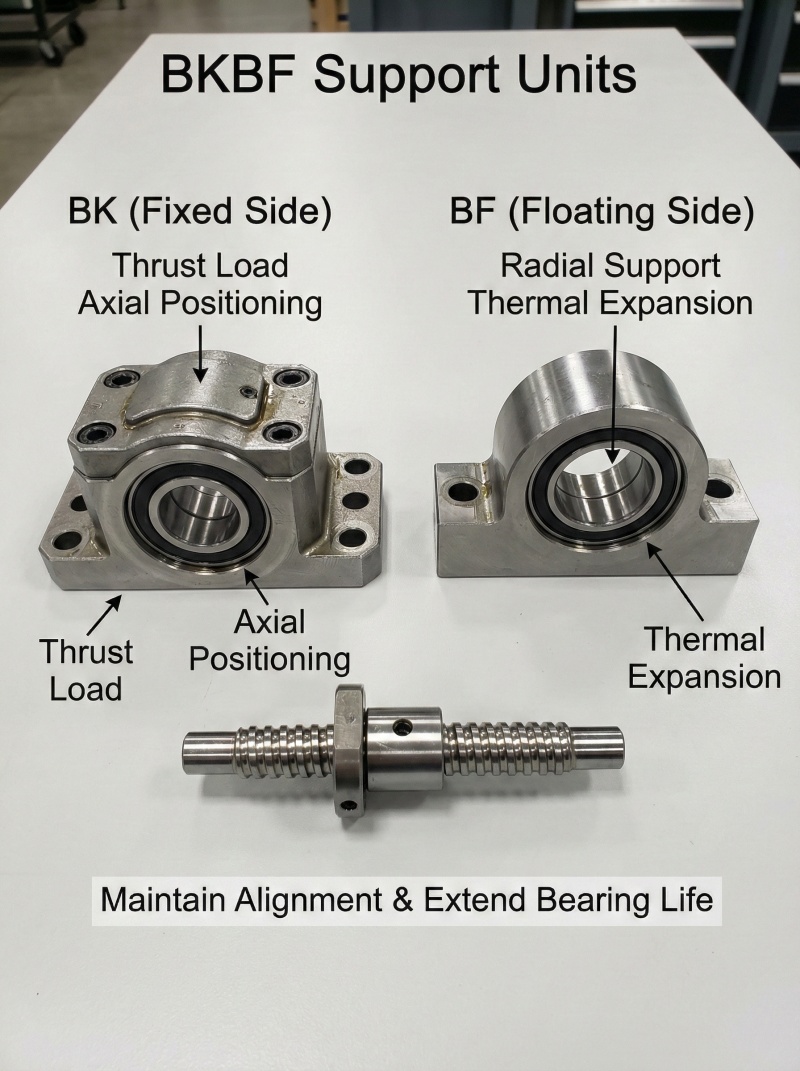

What Are BKBF Support Units?

BKBF support units are precision bearing blocks that secure and guide ball screw shafts in linear motion systems. The "BK" fixed-side unit constrains axial movement and absorbs thrust loads, while the "BF" floating-side unit provides radial support and accommodates thermal expansion.

- BK: Fixed end for thrust absorption and axial positioning

- BF: Support end for radial load and expansion compensation

- Maintains shaft alignment and extends bearing service life