Precision Bearing Housings for Reliable Motion Systems

High-quality bearing housings designed for precision, stability, and long-term reliability in mechanical transmission systems.

Common Challenges in Bearing Housing Selection

Are these issues affecting your production efficiency and equipment performance?

Dimensional Deviation

Poor dimensional accuracy causes mounting difficulties, forcing time-consuming adjustments during installation and delaying production schedules.

Premature Material Failure

Substandard materials lead to early bearing housing damage, increasing maintenance costs and creating unexpected downtime in critical operations.

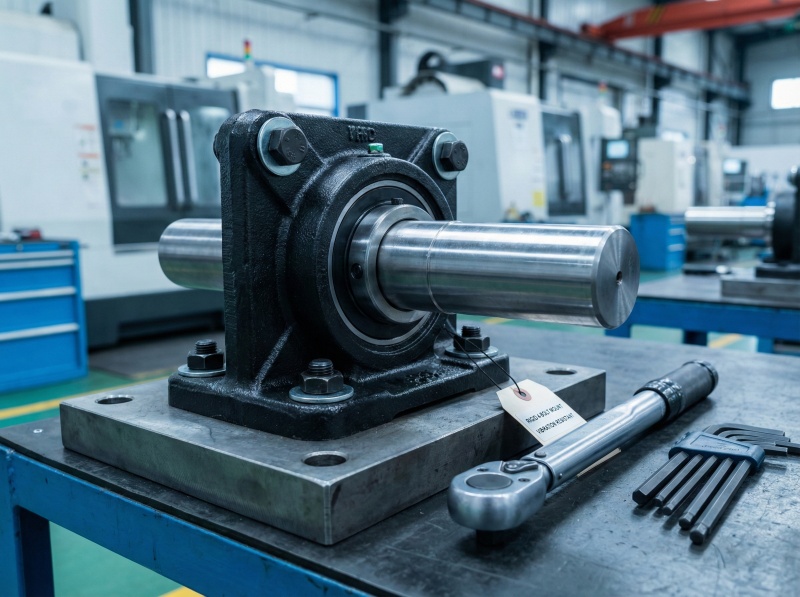

Vibration and Noise Issues

Excessive vibration compromises equipment precision, accelerates wear on adjacent components, and creates unacceptable noise levels in manufacturing environments.

Lack of Selection Guidance

Without proper technical support, buyers struggle to match bearing housings to their specific applications, resulting in performance issues and wasted investment.

Inventory and Lead Time

Insufficient stock availability creates delivery delays, disrupting project timelines and forcing expensive expedited shipping or production stoppages.

Poor After-Sales Response

Slow technical support leaves buyers without solutions when problems arise, extending downtime and increasing frustration during critical maintenance periods.

Ready to eliminate these challenges from your operations?

Discover Our SolutionsWhy Choose Our Bearing Housings

Engineered solutions that directly address your most critical operational challenges

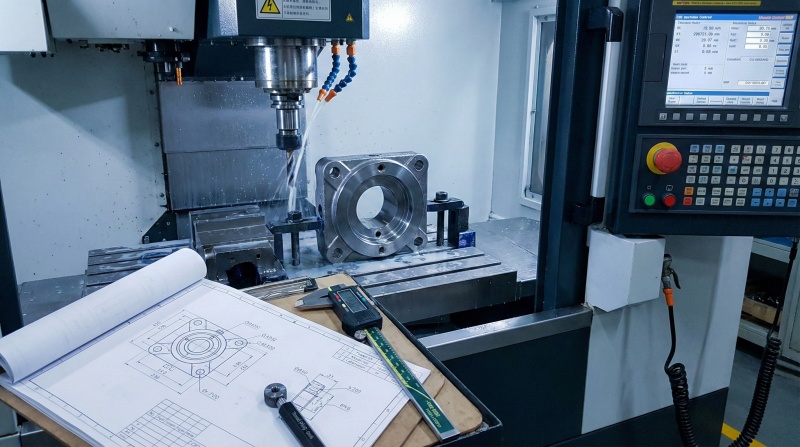

Precision CNC Machining

Advanced CNC technology ensures dimensional tolerance within ±0.01mm, guaranteeing perfect fit every time and eliminating installation headaches that waste valuable production time.

Premium Material Selection

High-strength cast iron and aluminum alloys provide exceptional durability and stability, extending service life by up to 3x compared to standard materials while maintaining consistent performance.

Ready Stock Availability

Extensive inventory of common models enables same-day or next-day shipping, keeping your projects on schedule and eliminating costly delays from extended lead times.

Expert Engineering Support

Dedicated technical team provides comprehensive selection guidance based on your load requirements, operating conditions, and performance goals, ensuring optimal product match for your application.

100% Inspection Protocol

Rigorous quality control system inspects every single unit before shipment, guaranteeing batch-to-batch consistency and eliminating the risk of defective products disrupting your operations.

Rapid Technical Response

Professional after-sales team delivers solutions within 4 hours during business days, minimizing downtime and providing the technical confidence you need for smooth operations.

Experience the difference that precision engineering makes

Request Technical ConsultationComplete Bearing Housing Solutions

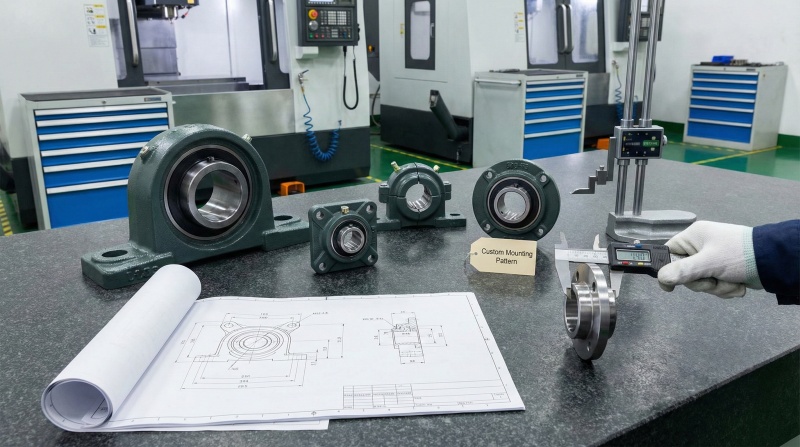

Comprehensive range of bearing housings engineered for diverse industrial applications and mounting requirements

Pillow Block Housing

Versatile self-aligning design for standard shaft mounting applications. Features robust base for stable installation and excellent load capacity in horizontal configurations.

View Details →

Flange Housing

Ideal for vertical shaft support and wall mounting scenarios. Compact footprint maximizes space efficiency while providing reliable axial and radial load support.

View Details →

Split Housing

Two-piece construction enables easy bearing replacement without shaft removal. Perfect for maintenance-intensive applications and reducing downtime during servicing.

View Details →

Square Housing

Rigid four-bolt mounting provides maximum stability for heavy-duty operations. Superior vibration resistance ensures precision performance in demanding industrial environments.

View Details →

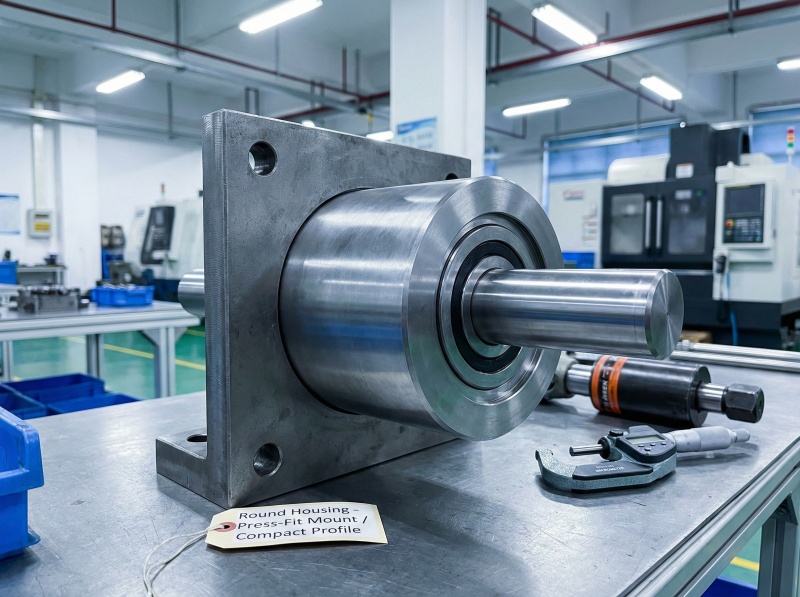

Round Housing

Cylindrical design for press-fit installation in machine frames. Streamlined profile offers space-saving benefits while maintaining structural integrity under continuous operation.

View Details →

Stainless Housing

Corrosion-resistant stainless steel construction for harsh environments. Excellent choice for food processing, chemical plants, and humid conditions requiring sanitary design.

View Details →Explore our complete bearing housing catalog with technical specifications

View All ModelsUnderstanding the Fundamentals of Bearing Housings

Bearing housings ensure alignment and protection, enabling smooth and stable mechanical motion.

Definition and Function

A bearing housing is a mechanical component that securely holds bearings in position while providing structural support for rotating shafts. It maintains proper alignment, distributes loads evenly, and protects bearings from contamination and external forces.

Key Structural Components

Primary elements include the housing body for structural integrity, bearing seat for precise fit, sealing system to prevent contamination, mounting holes for installation, and lubrication ports for maintenance access.

Working Principle

The housing constrains the bearing's outer race while allowing free rotation of the inner race with the shaft. This arrangement transfers loads from the shaft through the bearing to the housing structure, preventing shaft deflection and maintaining operational accuracy.

Impact on Mechanical Stability

Proper bearing housing selection directly affects equipment performance by ensuring shaft concentricity, minimizing vibration transmission, extending bearing service life, and maintaining precision alignment critical for production quality and operational efficiency.

Precision Fit

Tight dimensional tolerances ensure proper bearing seating, eliminating play that causes vibration and premature wear while maintaining shaft alignment accuracy.

Durable Materials

High-quality cast iron or aluminum alloys provide strength to withstand operational loads while resisting deformation under stress and temperature variations.

Lubrication System

Integrated grease ports and channels facilitate routine maintenance, ensuring bearings receive proper lubrication to minimize friction and extend operational life.

Easy Installation

Standardized mounting patterns and self-aligning capabilities simplify setup procedures, reducing installation time and minimizing risk of alignment errors during assembly.

Sealing Protection

Effective sealing systems prevent contamination from dust, moisture, and debris while retaining lubricants, crucial for maintaining bearing performance in challenging industrial environments.

Custom Options

Flexibility to modify dimensions, materials, and configurations allows precise matching to unique application requirements, optimizing performance for specialized operating conditions.

Want to learn how to choose the right bearing housing?

Read Technical Guide →Customization & OEM Capability

Flexible manufacturing solutions tailored to your exact specifications and branding requirements

Custom Shape & Size

Precision engineering enables modification of housing dimensions, mounting patterns, and geometric configurations to match your unique mechanical requirements and space constraints perfectly.

Logo Engraving

Professional laser engraving or embossing of your company logo, part numbers, and identification marks ensures brand consistency and traceability throughout your supply chain.

Special Coating

Advanced surface treatments including zinc plating, nickel coating, powder coating, and specialized corrosion-resistant finishes extend service life in demanding environmental conditions.

Precision Hole Machining

CNC drilling and tapping capabilities allow addition of custom mounting holes, lubrication ports, sensor mounting points, and cable routing passages to your exact specifications.

Package Customization

Tailored packaging solutions including custom cartons, protective foam inserts, retail-ready displays, and branded shipping materials meet your distribution and presentation needs.

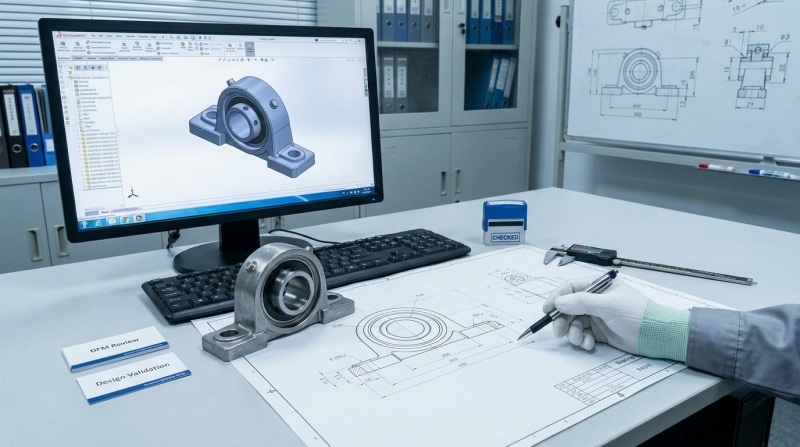

Technical Drawing Support

Experienced engineering team converts your concepts into production-ready CAD drawings, performs design validation, and optimizes manufacturability for cost-effective production.

Ready to bring your custom bearing housing design to life?

Start Your OEM ProjectManufacturing Process

Six-stage precision manufacturing system ensures consistent quality and performance

Raw Material Preparation

Premium-grade cast iron and aluminum alloys undergo rigorous incoming inspection for chemical composition and mechanical properties verification.

Precision CNC Machining

Advanced multi-axis CNC centers execute complex operations with ±0.01mm tolerance, ensuring dimensional accuracy for critical bearing seats and mounting surfaces.

Milling & Drilling

Secondary machining operations create mounting holes, lubrication channels, and custom features while maintaining precise angular and positional relationships.

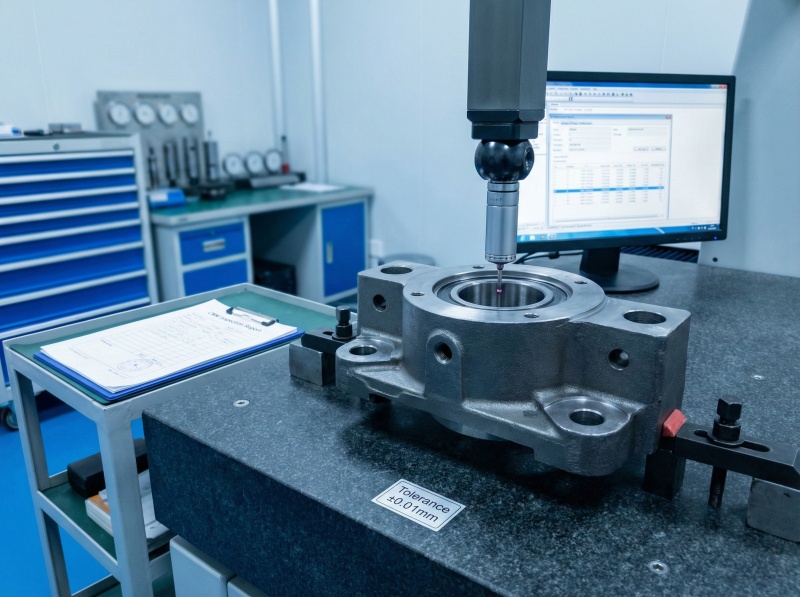

Inspection & Assembly

100% dimensional verification using CMM equipment confirms compliance with specifications before bearing installation and seal mounting in controlled environment.

Surface Finishing

Professional surface treatment including degreasing, phosphating, and powder coating application provides corrosion resistance and attractive appearance.

Final Packaging & Delivery

Careful packaging with rust prevention treatment, protective wrapping, and labeled cartons ensures product arrives in perfect condition for immediate installation.

Interested in visiting our manufacturing facility?

Schedule Factory TourBearing Housing Installation Guide

Step-by-step installation procedure for optimal performance and service life

Check Shaft Alignment and Clean Surface

Verify shaft straightness within 0.05mm tolerance and remove all dirt, debris, and protective coatings from mounting surfaces using appropriate cleaning solvents.

Apply Proper Lubrication

Fill bearing cavity to 50-70% capacity with manufacturer-recommended grease, ensuring even distribution around bearing elements without over-packing.

Insert Bearing into Housing

Carefully position bearing in housing seat, checking for proper seating depth and ensuring seals face correct direction according to environmental conditions.

Align and Tighten Mounting Bolts

Position housing on mounting surface, verify alignment using dial indicator, then torque bolts to specification in cross-pattern sequence to prevent distortion.

Verify Concentricity and Rotation

Measure shaft runout with dial gauge and manually rotate shaft to confirm smooth operation without binding or excessive resistance throughout full revolution.

Run Test for Vibration Level

Start equipment at low speed and progressively increase to operating RPM while monitoring vibration amplitude and temperature rise to confirm proper installation.

Need professional installation assistance?

Contact Technical SupportApplication Scenarios

Proven performance across diverse industrial sectors and demanding operating conditions

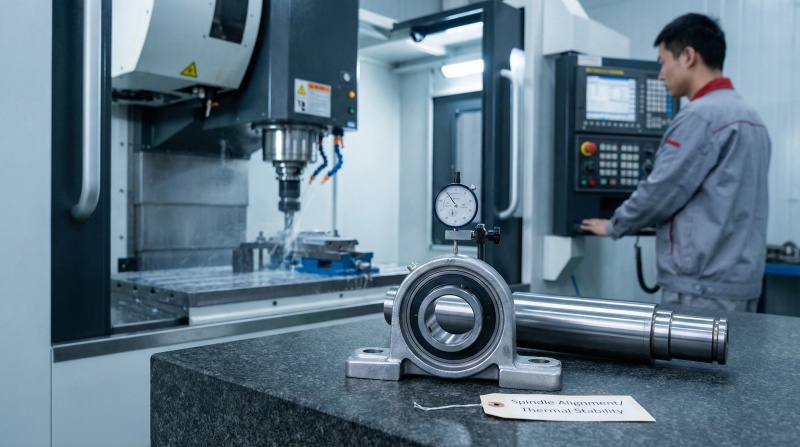

CNC Machinery

High-precision bearing housings maintain spindle alignment in CNC mills and lathes, ensuring machining accuracy while withstanding cutting forces and thermal expansion during continuous operation.

Conveyor System

Robust cast iron housings support conveyor rollers and drive shafts in distribution centers, providing reliable performance under heavy loads and dusty conditions with minimal maintenance requirements.

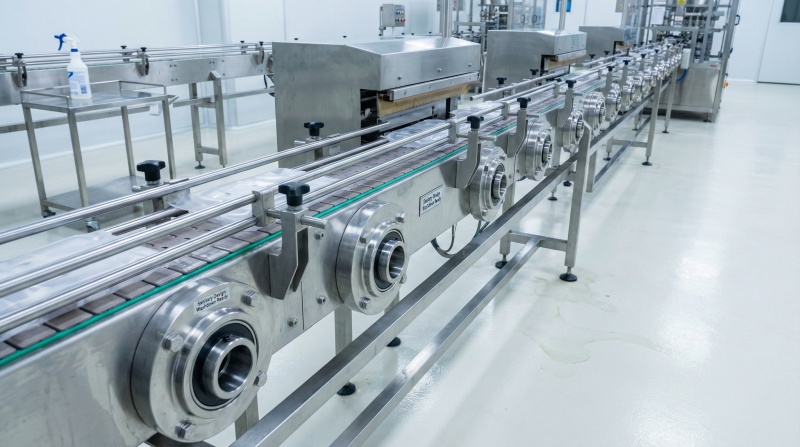

Packaging Equipment

Stainless steel housings excel in food packaging lines where sanitary design prevents contamination while sealed construction resists frequent washdowns and cleaning chemicals used in production.

Automation Lines

Lightweight aluminum housings reduce moving mass in robotic systems and pick-and-place units, enabling higher acceleration rates and improved cycle times without sacrificing structural integrity.

Textile Machines

Split bearing housings facilitate quick bearing replacement on spinning frames and weaving looms during scheduled maintenance, minimizing production downtime and maximizing equipment utilization rates.

Robotics

Precision-machined housings with tight tolerances support articulated robot joints, maintaining positional accuracy through millions of cycles while absorbing dynamic loads from rapid directional changes.

Discover which bearing housing solution fits your application

View Application GuideQuality Control & Inspection System

Comprehensive multi-stage quality assurance ensures every bearing housing meets exact specifications

Material Composition Test

Spectroscopic analysis verifies chemical composition of incoming materials, ensuring alloy specifications match requirements and metallurgical properties meet strength and durability standards.

Dimensional Accuracy Check

Precision measurement using CMM equipment confirms dimensional tolerance within ±0.01mm across critical features including bearing bore, mounting surfaces, and hole positions.

Surface Finish Inspection

Roughness measurement and visual inspection prevent surface defects that could cause premature wear, ensuring smooth bearing contact surfaces and proper seal mating.

Concentricity Measurement

Precision gauge testing confirms bearing bore concentricity relative to mounting surfaces, preventing shaft misalignment that causes vibration and accelerated bearing wear.

Corrosion & Salt Spray Test

Accelerated corrosion testing in salt spray chamber validates coating performance and rust resistance, ensuring housings withstand harsh environmental conditions throughout service life.

Final Assembly Audit

100% inspection protocol verifies bearing installation quality, seal positioning, lubrication adequacy, and overall assembly integrity before packaging and shipment authorization.

Request detailed quality control documentation for your project

View Our QC Report →Material Comparison

Understanding material properties helps you select the optimal bearing housing for your application requirements

| Material | Strength | Corrosion Resistance | Weight | Cost | Suitable For |

|---|---|---|---|---|---|

| Cast Iron | ★★★★★ | ★★☆☆☆ | Heavy | Low | Standard industrial use, heavy-duty applications, cost-sensitive projects |

| Aluminum Alloy | ★★★☆☆ | ★★★★☆ | Light | Medium | Automation equipment, lightweight systems, high-speed applications |

| Stainless Steel | ★★★★☆ | ★★★★★ | Medium | High | Food processing, chemical plants, humid environments, clean rooms |

Right material, right performance — choose what fits your system best. Cast iron offers maximum strength at lowest cost for general applications. Aluminum reduces weight for faster acceleration in automation. Stainless steel excels in corrosive environments where contamination prevention is critical. Our engineering team can help match material properties to your specific operating conditions.

Unsure which material suits your application?

Consult Our Material GuideCustomer Testimonials

Trusted by manufacturing companies worldwide for reliable bearing housing solutions

We've been ordering pillow block housings from this supplier for 2 years. The quality consistency is exceptional, and their technical support helped us optimize our automated assembly line. Zero defects in the last 6 months.

The custom split housing design they engineered for our mining conveyors reduced maintenance downtime by 40%. Their ability to handle large-volume orders with tight tolerances is impressive.

Excellent partnership for our heavy-duty machinery production. Their flange housings meet DIN standards perfectly, and the pricing is very competitive. Fast shipping to Europe is a big plus.

We needed stainless steel housings for food processing equipment. The quality exceeded expectations, and they provided all necessary FDA-compliant documentation. Highly recommend for sanitary applications.

Their square housings are perfect for our packaging machinery. The lead time is reasonable, and they always accommodate our rush orders during peak season. Excellent communication throughout.

Working with this supplier transformed our conveyor belt production efficiency. Their bearing housings are durable, and the custom branding option helped our OEM business. Great long-term partner.

Join 500+ satisfied customers worldwide

Read More FeedbackGlobal Projects & Export Experience

Serving manufacturers worldwide with proven export capabilities and international quality standards

Discover how we can support your global operations

Explore Our Global Network →Request a Quote / Contact Form

Get in touch with our engineering team for technical consultation and fast quotation

Talk Directly with Our Engineer Team

Our technical experts are ready to assist with product selection, custom design, and application engineering. Fast quotation with 24-hour response guarantee.

Response Time

Within 4 hours during business days

Languages

English, Chinese, Technical Support

Business Hours

Monday - Friday: 8:00 AM - 6:00 PM (GMT+8)

Location

China, serving customers worldwide