High Precision Ball Screws for Industrial Automation

Engineered to deliver exceptional positioning accuracy and reliability for your most demanding motion control systems

Get QuoteCommon Challenges When Sourcing Ball Screws

Understanding your concerns helps us deliver better solutions. Here are the critical issues affecting production efficiency and equipment performance.

Poor Accuracy

Excessive positioning errors cause product defects and reduce manufacturing yield, leading to costly rework and customer complaints.

Short Service Life

Premature wear forces frequent replacements, increasing downtime and maintenance costs while disrupting production schedules.

Technical Communication Gap

Suppliers without engineering expertise struggle to understand your specifications, resulting in wrong selections and project delays.

Excessive Noise

Loud operation indicates bearing wear or poor assembly quality, signaling impending failure and reducing equipment lifespan.

Inferior Materials

Low-grade steel causes rapid wear and jamming, compromising smooth motion and requiring premature system overhaul.

Inconsistent Quality

Performance variations between production batches make maintenance unpredictable and complicate inventory management.

These challenges don't have to slow your production. Let's solve them together.

Discuss Your RequirementsEngineered for Precision and Durability

Our ball screws combine advanced manufacturing technology with premium materials to deliver consistent performance across millions of cycles.

±0.005mm Precision

CNC thread grinding ensures repeatable accuracy across the entire stroke length, eliminating positioning errors that compromise product quality.

Premium Alloy Steel

SCM440 chromium-molybdenum steel with vacuum heat treatment achieves 58-62 HRC hardness, resisting wear for extended operational life.

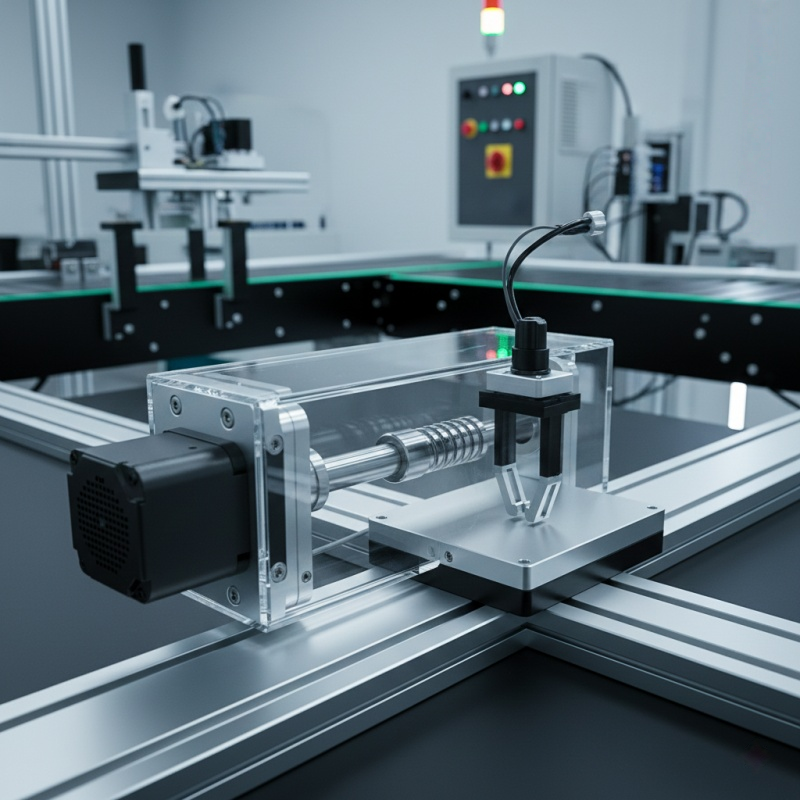

Automated Grinding

German-technology grinding machines maintain thread profile consistency, ensuring smooth ball circulation and eliminating backlash.

Anti-Corrosion Treatment

Black oxide or nickel plating protects against rust in humid environments, maintaining performance in challenging industrial conditions.

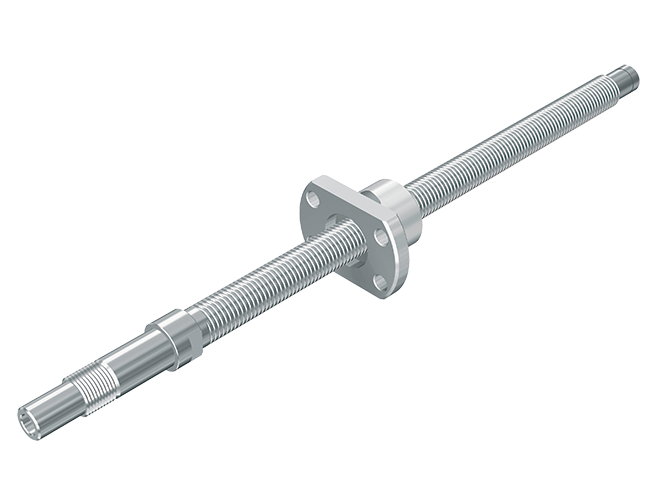

Custom End Machining

Shaft ends machined to your drawings with keyways, threads, or flanges—ready for direct installation without additional modification.

Factory Direct Supply

Eliminate distributor margins and reduce lead times with direct manufacturer access, getting components faster at competitive pricing.

Experience the difference that precision engineering makes in your production line.

Request Technical SpecificationsWhy Clients Choose Our Ball Screws

We address each pain point with concrete solutions backed by manufacturing expertise and quality systems that ensure consistent results.

Guaranteed Consistency

Advanced CNC grinding centers maintain identical specifications across all units, eliminating batch-to-batch variations that complicate equipment setup and maintenance planning.

Engineering Expertise

Our technical team understands load calculations, critical speeds, and preload requirements—providing selection guidance that prevents costly misapplication and ensures optimal performance.

Flexible Customization

Mix different models in single orders with custom leads, nut types, and lengths—eliminating minimum order constraints that force oversized inventory investments.

Dual Quality Verification

Coordinate measuring machines verify both geometric accuracy and functional performance under load, catching defects before shipment rather than after installation.

Rapid Response

Engineering-focused sales team provides detailed quotations within hours, not days—accelerating your project timeline and reducing procurement cycle stress.

Installation Support

Application engineers assist with mounting alignment, preload adjustment, and troubleshooting—ensuring proper installation that maximizes component life and system performance.

Partner with a manufacturer who understands both your technical needs and business pressures.

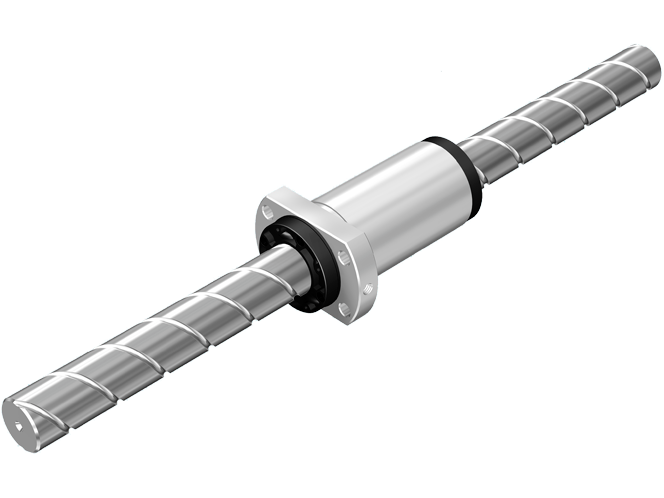

Start Your ProjectOur Featured Ball Screw Models

Industry-standard configurations ready for immediate integration into your motion systems, with custom options available for specialized requirements.

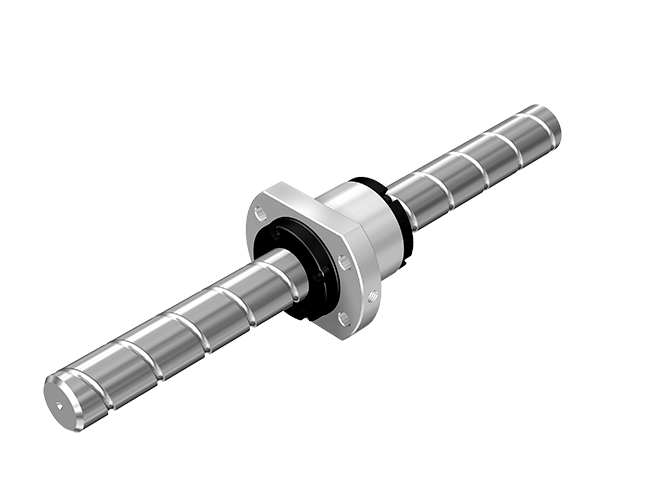

SFU1605

C7 PrecisionIdeal for 3D printers, engraving machines, and light-duty CNC applications requiring cost-effective precision positioning with 16mm diameter shaft.

View Details

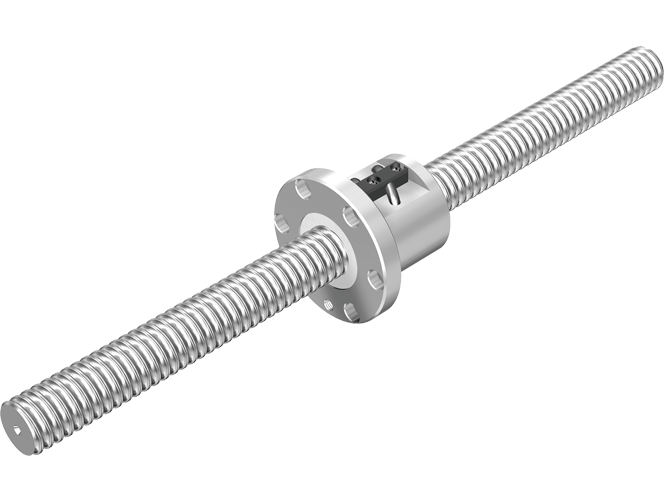

SFU2005

C5 PrecisionPerfect for CNC milling machines and industrial robots demanding higher rigidity and accuracy, supporting increased thrust loads with 20mm shaft.

View Details

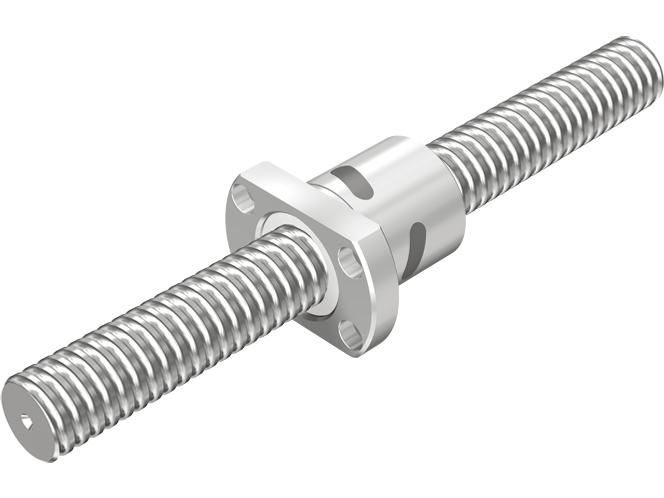

SFU2504

C5 PrecisionDesigned for medical equipment and semiconductor manufacturing where stainless steel construction prevents contamination and corrosion in clean environments.

View Details

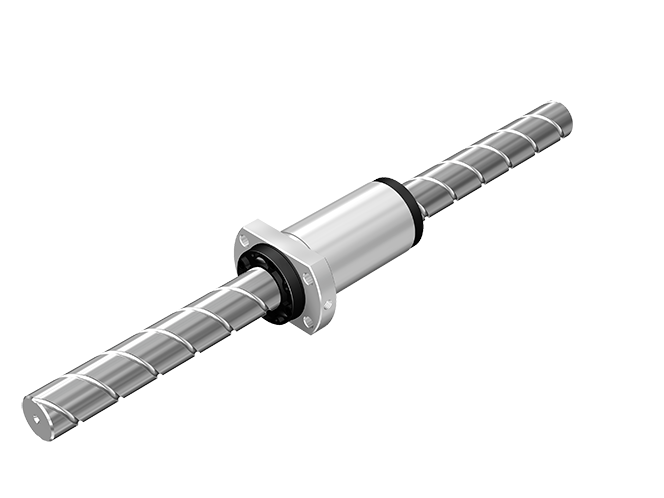

SFU3205

C7 PrecisionHeavy-duty solution for plasma cutting tables and large gantry systems requiring maximum load capacity with 32mm diameter shaft and robust construction.

View Details

SFU4008

C5 PrecisionPremium choice for injection molding machines and press brakes where 40mm shaft diameter provides exceptional rigidity for high-force applications.

View Details

Custom Models

C3-C10 AvailableSpecialized configurations with non-standard leads, preload options, and unique end machining tailored to your exact application requirements.

View DetailsCan't find the exact specification? Our engineering team can create custom solutions for unique applications.

Request Custom QuoteTechnical Specifications

Detailed dimensional and performance parameters for precise system integration

| Model | Dimensions | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d | Lead | Ball Dia | D | A | B | L | W | X | H | Q | NO.of Circuite | |

| SFU1204-4 | 12 | 4 | 2.381 | 22 | 40 | 10 | 40 | 32 | 4.5 | 30 | 4 | |

| SFU1604-4 | 16 | 4 | 2.381 | 28 | 48 | 10 | 40 | 38 | 5.5 | 40 | M6 | 4 |

| SFU1605-3 | 5 | 3.175 | 28 | 48 | 10 | 43 | 38 | 5.5 | 40 | M6 | 3 | |

| SFU1605-4 | 5 | 3.175 | 28 | 48 | 10 | 50 | 38 | 5.5 | 40 | M6 | 4 | |

| SFU1610-3 | 10 | 3.175 | 28 | 48 | 10 | 47 | 38 | 5.5 | 40 | M6 | 3 | |

| SFU2005-3 | 20 | 5 | 3.175 | 36 | 58 | 10 | 43 | 47 | 6.5 | 44 | M6 | 3 |

| SFU2005-4 | 5 | 3.175 | 36 | 58 | 10 | 51 | 47 | 6.6 | 44 | M6 | 4 | |

| SFU2010-3 | 10 | 3.175 | 36 | 58 | 10 | 47 | 47 | 6.6 | 44 | M6 | 3 | |

| SFU2505-4 | 25 | 5 | 3.175 | 40 | 63 | 10 | 51 | 51 | 6.6 | 48 | M6 | 4 |

| SFU2510-4 | 10 | 3.175 | 40 | 63 | 12 | 85 | 51 | 6.6 | 48 | M6 | 4 | |

| SFU3205-4 | 32 | 5 | 3.175 | 50 | 81 | 12 | 52 | 65 | 9 | 62 | M6 | 4 |

| SFU3206-4 | 6 | 3.175 | 50 | 81 | 12 | 57 | 65 | 9 | 62 | M6 | 4 | |

| SFU3210-4 | 10 | 6.35 | 50 | 81 | 14 | 90 | 65 | 9 | 62 | M6 | 4 | |

| SFU4005-4 | 40 | 5 | 3.175 | 63 | 93 | 14 | 55 | 78 | 9 | 70 | M8 | 4 |

| SFU4010-4 | 10 | 6.35 | 63 | 93 | 14 | 93 | 78 | 9 | 70 | M8 | 4 | |

| SFU5005-4 | 50 | 5 | 5.175 | 75 | 110 | 15 | 55 | 93 | 11 | 85 | M8 | 4 |

| SFU5010-4 | 10 | 6.35 | 75 | 110 | 16 | 93 | 93 | 11 | 85 | M8 | 4 | |

| SFU5020-4 | 20 | 7.144 | 75 | 110 | 16 | 138 | 93 | 11 | 85 | M8 | 4 | |

| SFU6310-5 | 63 | 10 | 6.35 | 90 | 125 | 20 | 97 | 108 | 11 | 100 | M8 | 5 |

| SFU8010-6 | 80 | 10 | 6.35 | 105 | 145 | 20 | 98 | 125 | 13.5 | 110 | M8 | 6 |

Customization Possibilities

Flexible manufacturing capabilities allow us to adapt every aspect of ball screw design to your unique operational requirements and space constraints.

Shaft Diameter & Lead Range

Specify any shaft diameter from 12mm to 80mm and lead values from 1mm to 40mm, enabling precise matching to your torque, speed, and positioning requirements.

Custom Nut Design

Choose from flange, cylindrical, or custom-shaped nuts with variable preload settings, return tube options, and specialized mounting patterns for direct integration.

Coating & Plating Selection

Select from black oxide, nickel, chrome, or Teflon coatings based on your environment—providing corrosion resistance, reduced friction, or food-grade compliance as needed.

End Machining Per Drawing

Upload your CAD drawings for precisely machined shaft ends including keyways, threads, tapers, or mounting flanges—eliminating post-delivery modifications and installation complexity.

Preload Tuning

Factory-set preload eliminates backlash for applications requiring bidirectional accuracy, with light, medium, or heavy preload options matching your stiffness and smoothness priorities.

Material Customization

Beyond standard SCM440 steel, we offer stainless steel 304/316 for corrosion resistance, carbon steel for economy, or specialized alloys for extreme temperature environments.

Every customization is engineered to enhance your system performance while simplifying integration.

Discuss Custom RequirementsOEM / ODM Workflow

Transparent 10-step process ensures accurate specifications, quality verification, and on-time delivery for every custom order.

Inquiry

Submit specifications or application details through email, form, or direct contact with technical team.

Drawing Confirmation

Engineers review requirements and create detailed technical drawings for your approval and verification.

Quotation

Receive comprehensive pricing including tooling, unit costs, and delivery timeline within 24 hours.

Sampling

Physical prototypes produced to validate design, material selection, and manufacturing process accuracy.

Accuracy Test

CMM inspection verifies dimensional accuracy, lead error, and surface finish against specifications.

Feedback

Client reviews samples and test reports, requesting modifications or approving for mass production.

Production

Full-scale manufacturing begins using approved specifications and validated process parameters.

QC

100% inspection of critical dimensions plus statistical sampling for comprehensive quality verification.

Packing

Individual protection with oil paper, foam padding, and moisture barriers in wooden crates for safe transit.

Delivery

Shipment via express, air, or sea freight with full tracking and documentation for customs clearance.

Every step is designed to minimize risk and maximize the likelihood of first-time-right production success.

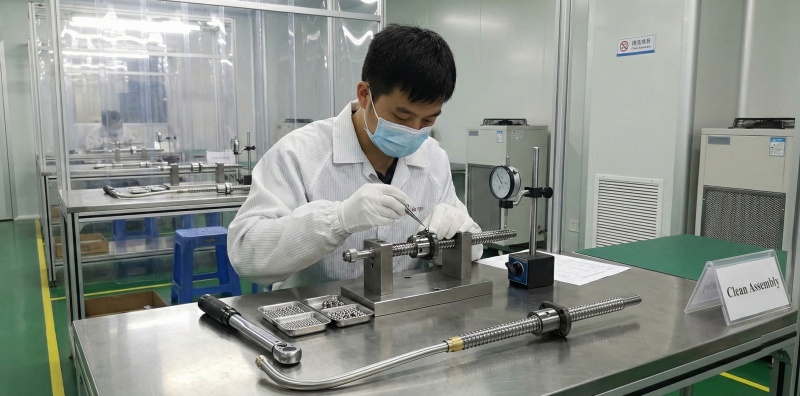

Start Your Custom ProjectPrecision Manufacturing Process

Six critical stages combine advanced machinery with skilled craftsmanship to deliver consistently accurate ball screws that perform reliably over millions of cycles.

Material Cutting

Premium alloy steel bars precisely cut to length with tight tolerance control, removing material stress and ensuring dimensional stability throughout machining.

Thread Grinding

CNC grinding machines create precise ball grooves with controlled lead accuracy and surface finish, forming the foundation for smooth motion and long service life.

Heat Treatment

Vacuum hardening achieves 58-62 HRC surface hardness while maintaining core toughness, dramatically increasing wear resistance and extending operational lifespan.

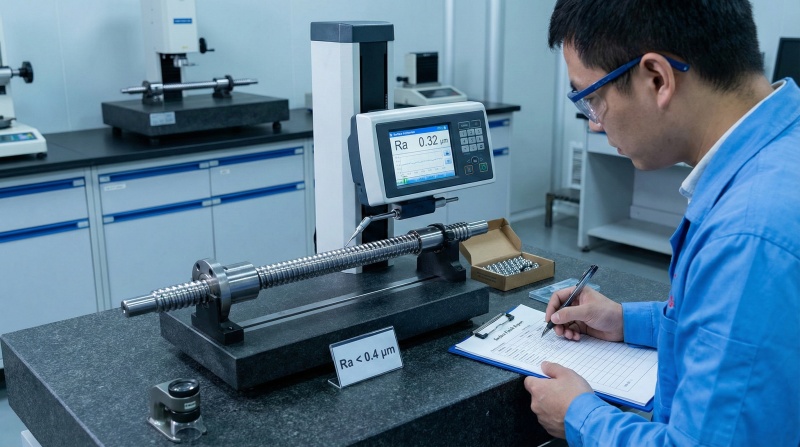

Polishing

Precision polishing reduces surface roughness to Ra 0.4μm or better, minimizing friction and noise while enabling smooth ball circulation through the raceway.

Assembly

Clean room assembly prevents contamination as precision-graded balls are loaded into nuts, with preload adjustment and return tube installation verified by functional testing.

Final Inspection

CMM verification confirms lead accuracy, dimensional compliance, and geometric tolerances with full documentation, ensuring only conforming units reach customers.

Decades of manufacturing expertise ensure consistent quality from first piece to last in every production run.

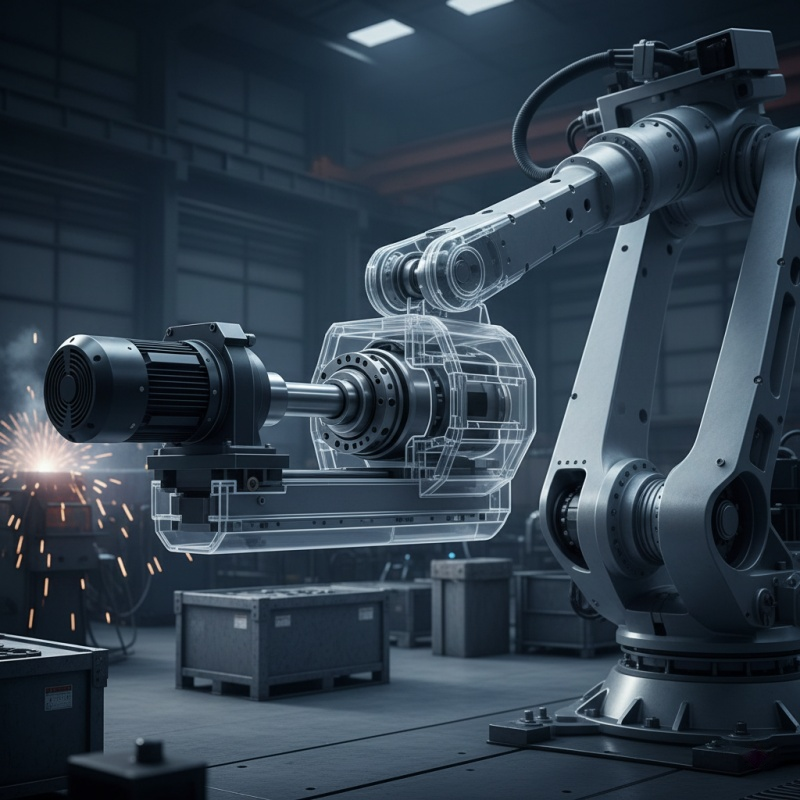

Learn About Our FacilityApplications of Ball Screws

Proven performance across diverse industries where precision motion control is critical to product quality, process efficiency, and operational reliability.

Whatever your application, our engineers can recommend the optimal ball screw configuration for your performance requirements.

Find Your Application SolutionProfessional Engineering Support

Comprehensive technical assistance throughout product selection, installation, and operational optimization ensures maximum performance and system reliability.

-

Design Consultation

Engineers review your application requirements including loads, speeds, and environmental factors to recommend optimal ball screw specifications that prevent over-engineering or under-specification.

-

Sample Verification

Pre-production samples allow functional testing in your actual equipment, validating mechanical fit, motion smoothness, and performance characteristics before committing to volume production.

-

Installation Guidance

Detailed installation procedures cover mounting techniques, bearing support methods, coupling selection, and alignment tolerances—preventing installation errors that compromise performance or accelerate wear.

-

After-Sales Maintenance

Technical support continues post-delivery with troubleshooting assistance, maintenance scheduling recommendations, and lubrication guidance to maximize service life and minimize unexpected downtime.

Access engineering expertise that bridges the gap between component specifications and system performance.

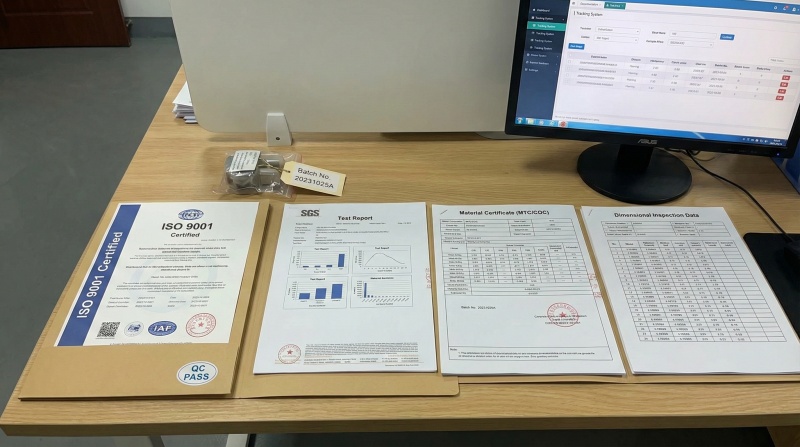

Connect With Our EngineersStrict Quality Control for Every Batch

Multi-stage inspection protocols and advanced testing equipment ensure dimensional accuracy, functional performance, and long-term reliability meet or exceed industry standards.

Precision Inspection

Coordinate measuring machines verify lead accuracy, pitch error, and straightness to ±0.005mm tolerance, confirming geometric specifications match design requirements before assembly.

Surface Finish Testing

Profilometers measure raceway surface roughness to confirm Ra values below 0.4μm, ensuring smooth ball circulation without micro-pitting that causes premature wear or increased friction.

Noise Testing

Sound level meters detect abnormal vibration or bearing defects during rotation tests, identifying assembly issues or ball quality problems before units leave the factory.

Hardness Testing

Rockwell testing confirms surface hardness reaches 58-62 HRC after heat treatment, validating metallurgical properties necessary for wear resistance and extended service life.

Load Testing

Dynamic load testing under rated conditions validates thrust capacity, preload maintenance, and nut return tube functionality, ensuring reliable performance under operational stresses.

Certification Documentation

ISO 9001 certified manufacturing with complete test reports, material certificates, and dimensional inspection data provided with every order for traceability and compliance verification.

Quality assurance isn't just testing—it's a commitment to delivering components that perform as promised.

Review Our Quality StandardsSecure Packaging & Global Delivery

Professional packaging protects precision components during transit while flexible shipping options ensure timely delivery to manufacturing facilities worldwide.

Protective Packaging

Each ball screw wrapped in oil paper to prevent corrosion, cushioned with PE foam tubes protecting threads and ends, then sealed in plastic film with desiccant packs controlling moisture exposure during storage and transport.

Wooden Crate Transport

Heavy-duty plywood crates with internal bracing prevent shifting during handling, while fumigation certification meets international shipping regulations for ocean freight to any destination globally without customs complications.

Global Express & Freight

Small orders ship via DHL/FedEx for 5-7 day delivery, while larger quantities use consolidated ocean freight with door-to-door service including customs clearance assistance, ensuring predictable arrival times for production scheduling.

From factory floor to your receiving dock, we ensure components arrive in perfect condition ready for installation.

Discuss Shipping OptionsTrusted by Global Manufacturers

Real feedback from engineering teams and procurement managers who rely on our ball screws for their most demanding applications.

We switched to these ball screws for our automatic screw-driving machines after quality issues with our previous supplier. The positioning accuracy improved immediately, reducing our defect rate by 35%. The engineering support during selection was outstanding—they understood our torque requirements and recommended the perfect preload configuration.

For our robotic welding systems, reliability is everything. These ball screws have been running three shifts daily for over two years with zero failures. The consistent quality between batches means we can order with confidence knowing every unit will perform identically. The technical documentation made integration straightforward, saving weeks of development time.

We needed custom lengths and end machining for our CNC router retrofit project. The team provided CAD drawings for approval within 24 hours and delivered samples in two weeks. The custom keyway machining was perfect—no secondary operations needed. Lead time and pricing beat three other quotes, and the ball screws have exceeded performance expectations.

Join hundreds of manufacturers who have improved their equipment performance and reduced maintenance costs.

Share Your RequirementsRequest a Quote or Send Your Drawing

Let our engineers help you find the perfect ball screw solution. Submit your specifications or upload technical drawings for fast, accurate quotations.

Why Work With Us?

Our engineering-focused approach ensures you get exactly the right ball screw for your application, not just what we have in stock.

- Response within 4 business hours

- Technical consultation included

- Free sample evaluation available

- Custom specifications welcomed

- Competitive factory-direct pricing

- Global shipping arrangements

Upgrade Your Motion System Efficiency Today!

Let our engineers design your perfect solution with precision ball screws engineered for performance, reliability, and long service life.